Breakwater

BREAKWATER, a barrier intended to break the force of water at a particular place. A breakwater provides the arti ficial protection necessary, when a harbour is formed in an ex posed situation, to supplement or complete such natural shelter as may be afforded by the configuration of the coast line or by the presence of outlying islands, reefs, etc. (see also the article HARBOURS). Although a harbour pier or jetty may be so placed and built as to serve the double purpose of a berthing place and a breakwater, the term breakwater is generally confined to a struc ture used solely for protection; indeed, in some cases break waters are isolated, so as to be cut off by water from the shore, as at Plymouth.

Breakwaters must be made sufficiently strong to withstand the impact of the waves during the worst storms to which they are exposed. It is therefore essential, before constructing a break water, to investigate carefully the exposure of the site, the dis tance of any sheltering land in the most stormy direction, the slope of the beach and the depth of the sea in the neighbourhood of the shore, and the protection, if any, afforded by outlying shoals or sandbanks. In a tidal sea, the height required for a breakwater and the extent of it exposed to breaking waves is affected by the difference in level between high and low water. The nature and the extent of any drift of sand or shingle along the shore must be ascertained. A study of the conditions of the cur rents is also necessary in order to avoid, in planning the works, the placing of the entrance to the sheltered area in such a position as to expose ships making the harbour to inconveniently strong cross-currents. These and other similar problems face the engi neer in planning the form and situation of the protective works of a harbour.

Winds.—Observations of the force, prevalence and direction of the winds belong to the science of meteorology (q.v.), but such records are valuable to the engineer in indicating from which di rections, open to the sea, the worst storms, and consequently the mum distance in a certain direction from the nearest land—or, as it is termed, the "f etch"—coincides with the line travelled by the strongest gales. The dimensions, indeed, of waves in the worst storms depend primarily on the extent of the sea in which they are raised; though in certain seas they are occasionally greatly increased by the exceptional velocities attained by hurri canes and typhoons.

Waves have been found to attain a maximum height (measured from trough to crest) of about 2of t. in the Mediterranean, 2 5f t. in the Bay of Biscay and 4of t. in the Atlantic ocean ; whilst waves of 5c to 6oft. in height are said to have been observed in the south Atlantic ocean off the Cape of Good Hope, where the ex panse of sea reaches a maximum. The length of large waves bears no definite relation to their height, and is apparently due, in the long waves often observed in exposed situations, to the combina tion of several shorter waves in their onward course. Thus waves of over 600ft. in length have been met with during severe gales in the Atlantic ocean; whilst waves from 600 to i,000ft. long are regarded as of common occurrence in the Pacific ocean during storms.

The rate of transmission of the undulation also varies with the exposure ; for the ordinary velocity of the apparent travel of waves in storms has been found to amount to about 22m. an hour in the Atlantic ocean, and to attain about 27m. an hour off Cape Horn. The large waves observed in mid-ocean do not, greatest waves, may be expected. Moreover, it is necessary for constructing or repairing a breakwater to know the period of the year when the calmest weather may be safely anticipated. In the parts of the world subject to periodical winds such as the mon soons, the direction and force of the winds vary with remarkable regularity according to the seasons, and even such uncertain oc currences as hurricanes and cyclones generally visit the regions in their track at definite periods of the year, according to the locality.

Waves.—The size of waves depends on the force of the wind and the distance along which it blows continuously, in ap proximately the same direction, over a large expanse of ocean. The greatest waves are, accordingly, encountered where the maxi however, reach the coast, because their progress is checked and their height and length reduced by encountering the shelving sea-bottom on approaching the shore.

The actual waves which have to be arrested by breakwaters therefore depend on the exposure of the site, the existence of con tinuous deep water close up to the shore and the depth in which the breakwater is situated. On the other hand, the height and con sequently the destructive force of waves are increased on running up a funnel-shaped bay by the increasing concentration of the waves in the narrowing width, just as the tidal range of a moderate tidal current is much augmented by its passage up the bay of Fundy, or the Bristol channel into the Severn estuary. This effect is intensified when the bay faces the direction of the strongest winds. Thus at Wick, on the north-east coast of Scotland, a mass of masonry weighing 1,35o tons, placed at the head of the break water projecting halfway across the bay and facing the entrance, was moved by the waves during a violent storm. On the same coast, a portion of Peterhead breakwater, weighing 3,30o tons, was shifted tin. in 1898. It has been estimated that the wave stroke necessary to move this mass amounted to 2 tons per sq.f t.

on the average over the face of the displaced wall. At Bilbao in Spain, where the bay, like that of Wick, is funnel shaped, a monolithic mass of 1,70o tons weight at the breakwater end was carried 1o5ft. into the harbour during a severe gale (Dec. 1894).

Where outlying sandbanks stretch in front of a coast, as for instance the sandbanks opposite Yarmouth sheltering Yarmouth roads, large waves cannot approach the land, for they break on the sandbanks outside. Waves indeed always break when, on running up a shoaling beach, they reach a depth approximately equal to their height; and the largest waves which can reach a shore protected by intervening sandbanks are those which are low enough to pass over the banks without breaking. Waves often break in depths of water greater than their own height, and any sudden change in the level of the sea bed over which a wave is travelling may bring about its disruption even in water of con siderable depth.

The force of the wind, as transmitted by degrees to the sea, is manifested as a series of progressing undulations without any material displacement of the body of water. So long as the wind continues to act on waves which it has brought into existence it continues to increase their height and length. The waves thus accumulate the energy which they receive from the wind. When a wave reaches a lee shore its energy has either to be dissipated by the breaking of the wave or to be reflected.

On encountering a vertical, or approximately vertical, obstacle to its onward course, each wave, on reflection, deals a blow against the obstacle proportionate to its size and rate of transmission. When a wave reaches shoal water the undulation is transformed into a breaking wave rushing up the sloping shore, till, on its energy being spent, it recoils back into the sea.

A breaking wave concentrates its transmitted force on a portion of the water forming the undulation, which consequently strikes a more powerful blow over a limited area against any structure than the more distributed shock of a simple undulation beating against a vertical wall. Moreover, the recoil or backwash of broken waves produces a greater scour than the simple reflection of an undulation from a vertical wall. The materials forming the covering of the slope and the toe of a breakwater mound must therefore be able to resist this erosive effect. The large concrete blocks often placed pell-mell as protection on the sloping face of a rubble mound breakwater absorb much of the energy of a breaking wave in their interstices and similarly reduce the force of the backwash. On the other hand, when a vertical surface is exposed to a heavy breaking wave a large mass of water is pro jected upwards and there is a heavy down stroke. Consequently the material at the toe of the wall is liable to displacement by the wash of recoil, unless the depth is sufficient to provide an ample cushion of water below the undulation. There are of course also stages of wave stroke to which a breakwater structure may be exposed which are intermediate between the complete breaker on a sloping beach and the pure reflection of a wave. (See also the articles WAVE THEORY and TIDES. Students of the subject should consult the works of Sir George Airy, Weber, Scott Russell, T. Stevenson, W. J. M. Rankine and W. H. Wheeler.) Protection of Unfinished Work.—The protection of un finished work during the seasonal periods of stormy weather is a difficult problem which has to be faced by the breakwater builder. Work may have to be entirely suspended for a portion of each year and the scar or unprotected end of the unfinished structure, exposed as it is on three sides out of four, is particularly liable to sea damage. At Bilbao, for instance, during the building of the main breakwater, long lengths at the outer end were destroyed year after year in the winter seasons. Special precau tions are usually taken to secure the safety of unfinished work in such circumstances.

Types of Breakwater.

Breakwaters may be classified under four general types : (I) a simple mound of stone rubble or con crete blocks, or a combination of the two materials; (2) a mound raised to near or above water level surmounted by a solid super structure of masonry or concrete; (3) a mound foundation fin ished off at a considerable depth below water level and surmounted by an upright wall breakwater of concrete or masonry; and (4) an upright wall breakwater, built up solid from the sea bottom to the top. The second and third types (frequently referred to as composite breakwaters) are, in fact, combinations of the first and fourth types. The classification is in some degree an arbitrary one, and examples can be cited in which one type merges in another. Generally, the choice of type is determined by the ma terials available at the site, the depth of water, the nature of the sea bed and, in some cases, by the facilities and plant which are available for the execution of the work. The length of time al lowable for the construction of a given length of breakwater has also, in some cases, a bearing on the Choice of design and method of construction.

(1) MOUND BREAKWATERS A rubble mound consists of a mass of stone, just as it is ob tained from a quarry, tipped into the sea along a predetermined line till the mound emerges out of the water. The stone is depos ited from barges or is carried to the work in wagons run out from the shore on staging ; frequently the two methods are com bined. The larger masses of stone are often selected for placing in the more exposed parts of the work and on the faces of the breakwater, and for this purpose the use of cranes may be neces sary. The mound thus deposited is gradually consolidated under the action of the sea and the weight of material. and a tolerably stable form is by degrees attained by continued deposits of stone. When the foundation is of soft and compressible material the stone rubble sinks into the sea bed owing to the weight of the super imposed materials. At Alexandria the rubble at the base of the north breakwater extension (1905-8) sank to a level of 2oft. be low the original bed, the silt of which was forced upwards at the sides of the mound.

The rubble mound system is wasteful of materials and entails a relatively high expenditure on maintenance. It can only be re sorted to where quarries near at hand are able to furnish large sup plies of stone at a cheap rate. When the site is an exposed one storm waves carry the stones on the top, if unprotected, forward on to the harbour slope, while the recoil of the wave on the outer face draws down' the stones on that side, thus flattening the slope. Frequent replenishing with a fresh deposit of stones is thus necessary. The inclination of the flattened sea slope, which ex tends from above high water to well below low water, depends on the exposure and the size of the stones on the face.

In order to avoid the injuries to which a rubble mound is sub jected by waves various methods have been devised for protect ing the top and the sea slope of the mound. For instance, the upper part of Plymouth, England, breakwater (fig. i) has been covered over by granite and limestone paving set in cement. In other cases the surface stones are selected, roughly masoned and set close together as at Portland, England (fig. 2) . The chief point of importance is to cover the outer slope and the top of the mound with the largest stones that can be procured, and when large stones are not readily obtainable concrete blocks furnish a convenient substitute.

Concrete Block Protection.

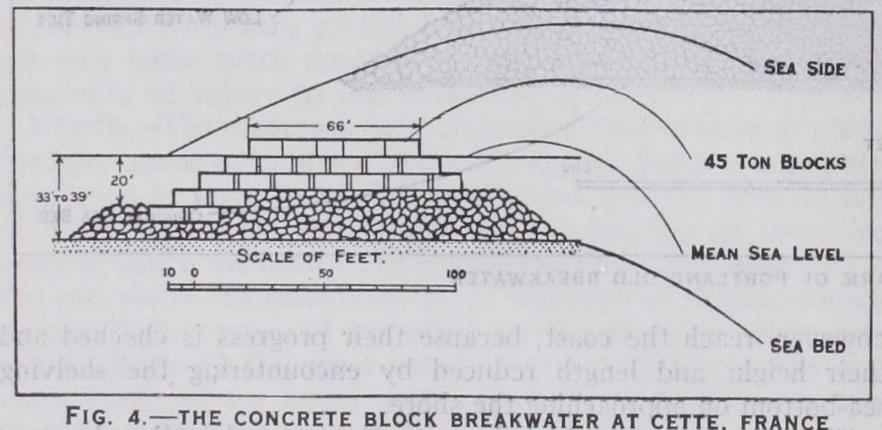

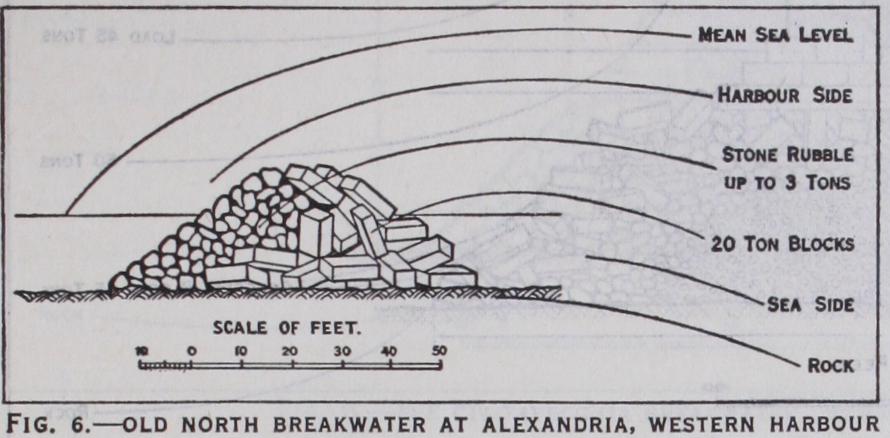

Where concrete blocks are em ployed it is usually as the outer covering on the top and sea slope of a rubble mound, as for example in the older breakwaters at Algiers, where the depth reaches loft., and at the ports of Cette and Bona (Algeria). The breakwater at Cette (fig. 4) has given trouble owing to the erosion of the sea bed and the unequal settle ment of the coursed blocks. A more usual arrangement is to deposit the blocks at random or pell-mell. Other examples of blockwork protection are the north-east breakwater at Colombo harbour, the extension of the west breakwater at Port Said (1912-22) (fig. 5) and the older part of the north breakwater at Alexandria (187o-74). In this case concrete blocks compose the outer half of the mound, sheltering the inner half consisting of small rubble (fig. 6). Occasionally a mound breakwater has been formed entirely with concrete blocks, as for instance the main portion of the western breakwater at Port Said (1864-68) (fig. 7).

Utility of Concrete

Blocks.—Concrete blocks possess the great advantage that they can be made wherever sand and shingle can be procured, and of a size only limited by the appliances which are available for handling them. In fact, in places where stone of any kind is difficult to procure at a reasonable cost, as for in stance at Port Said, concrete is indispensable. At Para (Brazil) blocks made of Portland cement and sand (without any stone or shingle) were used in the construction of the port works. Large artificial blocks, moreover, by enabling a comparatively steep slope to be formed with them on the sea side of a mound breakwater, reduce considerably the amount of materials required ; especially at exposed sites, and also for breakwaters extended into deep water. These large concrete blocks are deposited by cranes travel ling on staging or on the completed portion of the work, or are tipped into the sea from a sloping platform on barges, or floated out between pontoons, or slung out from floating cranes or der ricks. Sometimes when a mound breakwater has been raised out of water, advantage is taken of a calm period of the year and a low tide to form large blocks of concrete within timber framing on the top of the mound so as to afford additional protection.Advantages and Disadvantages of Mound Breakwaters. —The large mass of a mound breakwater gives it great stability; this type is, moreover, suited to construction on a sandy or silty sea bed. The large quantity of material required for its construc tion and the continuous maintenance necessary are, however, dis advantages. The type has, since the end of the i9th century, been employed to a limited extent, excepting perhaps in North Amer ica, and usually in comparatively sheltered positions of moderate depth. Well known examples of the mound breakwater, in addi tion to those already mentioned, are at Howth (the first example (2) MOUND BREAKWATERS WITH SOLID SUPER-STRUC, TURF AT OR NEAR WATER LEVEL This type is a modification of the first class and possesses most of its advantages and disadvantages. It comprises the majority of breakwaters constructed in the last quarter of the 19th and the early years of the 2oth centuries; but with the growing necessity of providing artificial shelter in great depths of water it has become more usual to build breakwaters in such situations with super structures carried down well below low water, as described later.

The solid superstructure reduces the amount of materials re quired, according to the depth at which it is founded, and the solid capping also serves to protect the top of the mound from the ac tion of the waves. In the case of a mound breakwater, portions of the highest waves generally pass over the top of the mound, and their force is also to some extent expended in passing through the interstices between the blocks or stones; whereas a super structure presents a solid face to the impact of the waves. A superstructure, accordingly, must be strongly built in proportion to the exposure and to the size of the waves liable to reach it. Special care, moreover, has to be taken to prevent the superstruc ture from being undermined, for the waves in storms, dashing up against this nearly vertical, solid obstacle, tend in their recoil down the face to scour and displace the materials of the mound at the outer toe of the superstructure and thereby undermine it. This risk is specially present where the superstructure is founded on the mound near low water level, and there is therefore no adequate cushion of water above the mound to withstand the recoil.

Superstructures.—The forms of superstructure exhibit con siderable variations, ranging from a few concrete blocks laid in courses on the top of the mound, or a paving protected by a parapet wall on the sea side, up to a solid structure which is some times of considerable height in situations where there is a large tidal variation. The object aimed at in the case of superstructures founded at or near low water level is to lay the foundations on the mound at the lowest level consistent with building a solid structure with stones or concrete blocks set in mortar, out of water in the ordinary manner. The desideratum in the case of superstructure foundations laid at some depth below low water (see section [3 ] These failures have led harbour engineers to recognize that destructive wave action can take place at depths of about soft. in situations of great exposure to the ocean, and down to more than 3oft. in the Mediterranean. In more sheltered positions the depths are proportionately less. Furthermore, the effect of the waves is at its maximum at sea level and the pressure of the wave on a vertical surface is more or less constant over the whole zone corresponding to the height of the wave, but below this zone it decreases rapidly (see E. Quellennec, Int. Congress of Navigation 1926, Paper 31). The pressure exerted at sea level by a wave in situations of great exposure may exceed three tons per square foot.

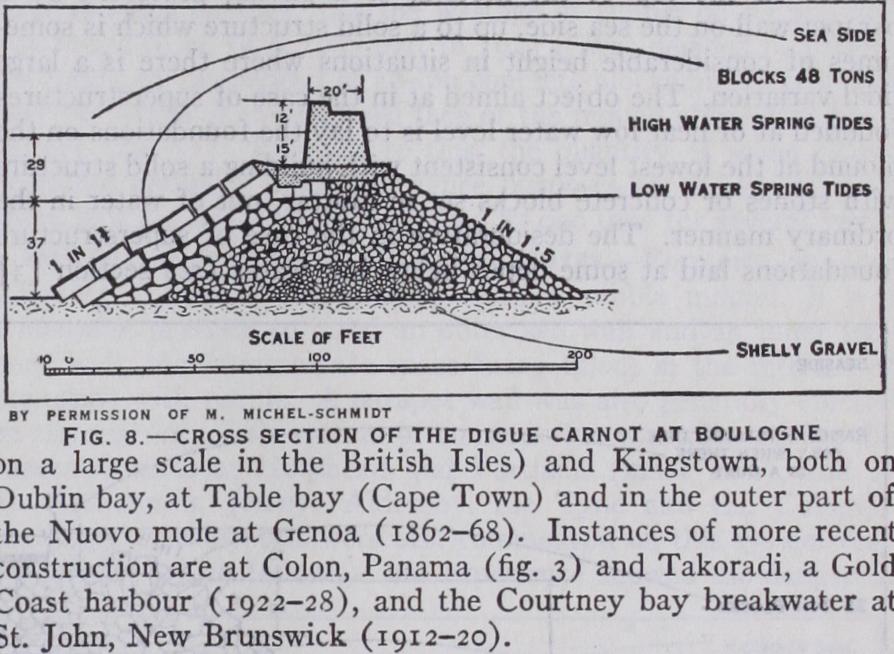

which follows) is to stop the raising of the mound at such a depth under water as to secure it from displacement by the waves. It is to the failure to provide adequately for this that the destruc tion or serious damage of many 19th century breakwaters is to be attributed. (See Sir W. Matthews, Proc. Inst. C.E., vol. clxxi. [19o8]. Sir Maurice Fitzmaurice has recorded, Proc. vol. ccxiv. [1922], that at Peterhead some 50-ton concrete blocks, joggled together and forming part of an apron protecting the rubble mound of breakwater about 45ft. below low water, were dis placed soft. and overturned during a gale.) Examples of rubble mound breakwaters surmounted by a super structure founded at or near low water or sea level are those at Cherbourg, Holyhead and Marseille, the Galliera and Giano moles at Genoa, the San Vincenzo mole at Naples, the east harbour breakwater at Alexandria, the digue Carnot at Boulogne, the north breakwater at Algiers and those at Fishguard, Le Havre, Oran, Civitavecchia and Casablanca, the latter in a much exposed posi tion on the Atlantic coast of Morocco (fig. 9). The very exposed breakwater at Alderney was commenced on this principle about the middle of the 19th century (see section [3] which follows).

The outer breakwaters at Leghorn and St. Jean de Luz have super structures founded at low water level on concrete block mounds. The breakwaters at Le Havre and Boulogne (fig. 8) are exam ples of the sorted mound surmounted by superstructure walls which, although founded well above low water, rise to a considera ble height on account of the large tidal range at these ports, viz., 242ft. and 29ft. respectively.

Marseille Breakwater.

The great breakwater at Marseille (see HARBOURS) is a successful example of the sorted rubble mound breakwater where a quay has been formed on the inner face, sheltered on the sea side by a narrow superstructure, founded at sea level, and protected on the sea slope of the mound from under mining by a wave breaker of large concrete blocks deposited pell mell (fig. 1o) on the rubble mound and having a flat slope from lowest water level up to the face of the superstructure wall well above highest sea level.

Other Mediterranean Breakwaters.

The outer portions of the San Vincenzo breakwater at Naples and the older parts of the Galliera mole at Genoa extend into depths of about 1 'oft. and 8oft. respectively, and have been provided with superstructures similar in type to, but more solid than, the superstructure at Marseille. The sorted rubble mounds are protected on the sea slope by stepped courses of concrete blocks from a depth of over Fishguard Breakwater.—The breakwater at Fishguard, con structed between 1900 and 1918, is an interesting example of a composite breakwater which, in spite of weaknesses inherent in the original design, has been made suitable to the exposed situa tion in which it has been installed. It was at first designed as a rubble mound carried up to about high water with concrete super structure and parapet ; but the wastage of rubble on its sea face was found to be so serious that in 1913 it was decided to protect the rubble by the deposit of 4o-ton concrete blocks placed pell-mell over the whole of the seaward face of the mound above low water springs (fig. 12). Previous to this, the quantity of stone rubble deposited annually for maintenance purposes on the sea face, of about half a mile in length, averaged 85,000 tons for several years.

Danger of Non-solid Superstructures.

Formerly, in con structing a large superstructure upon a rubble mound, it was a common practice to build an outer sea wall and an inner har bour wall, the intermediate space being filled, in the interest of economy, with rubble. A parapet wall was also generally erected on the sea side. This system of construction was adopted for the superstructures at Holyhead and Portland (inner arm), and at St. Catherine's, Jersey. Alderney, the Tyne and the Colombo south-west breakwaters were also commenced on this system (see section [3] which follows) ; but experience showed the danger in loft. below sea level. The outer extension of the main breakwater at Civitavecchia is an interesting example of the composite type of breakwater in which the rubble mound has been protected, and greatly reduced in volume and extent in deep water, by stepped courses of concrete blocks carried up from near the bottom of the mound (fig. 11). In all these cases, and in some other examples of similar construction, serious damage has occurred, largely due to the unequal settlement of the horizontally bedded courses of blocks. For this reason the Marseille type of sea face protection is to be preferred and is now generally adopted.exposed situations of a small breach in the comparatively weak outer wall, leading to the scouring out of the rubble filling and progressive destruction, and the practice was abandoned. (In certain cases the rubble filling was replaced by solid hearting.) Another cause of possible damage is due to the action of waves on the air which fills the interstices between the stones or blocks of mound and composite breakwaters. The violent compression of imprisoned air under a solid capping, or deck, exerts a destructive force which may blow up or displace the superstructure if its thickness and weight are not great enough to resist the pressure.

Breakwaters in North America.

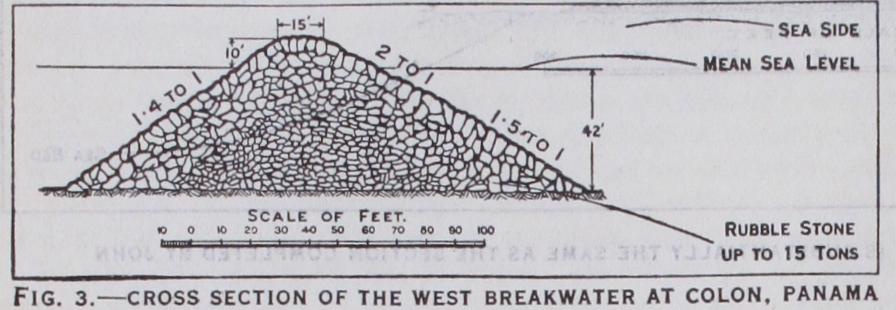

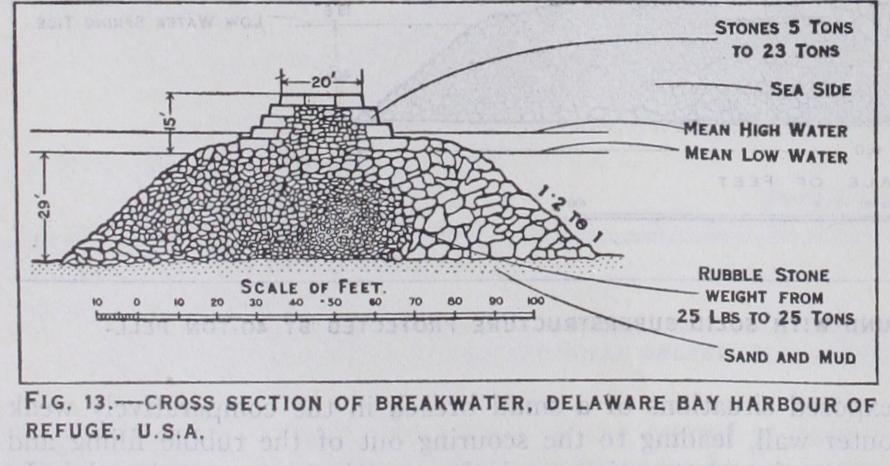

Many breakwaters con structed for forming harbours on the sea coasts of the United States and Canada and in the Great Lakes are of the rubble mound type. The two detached breakwaters sheltering the old Delaware harbour made many years ago were of this type. They were united towards the end of the 19th century by closing the gap between them, the new work being similar in section to that of the breakwater (fig. 13) formed in 1897-1901 for providing a harbour of refuge seaward of the original Delaware harbour. The breakwater, commenced in 1898, in San Padro bay, Los Angeles, in a depth of 48f t. at low water, is of the same form. A simple mound construction was adopted in 1910 for the Colon breakwater (fig. 3), when the construction of the Panama canal made the port, naturally a bad one, a harbour of impor tance.

(3) MOUND BREAKWATERS WITH SUPERSTRUCTURE BELOW LOW WATER As the main object of this class of breakwater is to keep the mound below the zone of wave disturbance in severe storms, it is evident that the depth at which the superstructure is founded should vary directly with the exposure and inversely with the size of the materials forming the mound.

Though composite breakwaters are still occasionally constructed with a superstructure founded on a rubble mound at, or above, low water, as described in the preceding section, the practice of placing the foundations at a considerable depth has become more usual. In Italian harbours, for instance, whereas at the close of the 19th century practically all the then existing breakwaters were of the former type, the deep submerged vertical-wall type has been adopted for nearly all breakwater construction in deep water since 1900. French engineers have, however, continued to favour the earlier form of the composite breakwater, the Marseille de sign being the prototype of most of the deep water breakwaters built by them during the first quarter of the loth century. They have, nevertheless, departed from this practice in the case of the later work carried out at Algiers, and it is probable that the fu ture extension of the breakwater at Marseille, to form the Bassin du Phare, in a depth exceeding iooft. will be similar to the Algiers design.

Alderney.

The depth at which wave action may adversely affect a rubble mound has been only very gradually realized. Thus in 1847 the Alderney breakwater, though fully exposed to the Atlantic ocean, was begun with a superstructure founded at low water upon a rubble mound. Within two years the foundations had to be carried 1 eft. below low water. This construction was adhered to up to close to the head, though the breakwater, com pleted in 1864, extended 4, 7oof t. from the shore into a depth of 13of t. at low tide, the spring rise being 18 feet. The recoil of the waves from the high superstructure wall brought about the degradation of the mound to a depth of 20 feet.

Colombo.

At Colombo, where the range of tide is only 2ft., the south-west breakwater (1875-85), which is exposed to the full force of the south-west monsoon, extends into a depth of 39ft. at low water. The superstructure was founded on a rubble mound croft. below low water. It is protected along its sea face by an apron of concrete in bags. The lesser depth of water and the lower superstructure, combined with the concrete bag protection, are factors which saved the breakwater from the failure which over took that at Alderney where the exposure is similar. Nevertheless, the experience gained of the action of the sea on the south-west breakwater led to the north-west detached breakwater at Colombo, of similar type, and constructed at a later date in a somewhat deeper but less exposed situation, being built with the foundations of the superstructure on the rubble mound placed at a depth of 3ift. below low water (fig. 14). In the building of the outer arm extension of the south-west breakwater (completed 1912) a sub merged wave breaker of 3o-ton concrete blocks deposited pell mell was constructed on the sea face of the upright wall (figs. 15 and 16), and this protection was extended along the whole of the sea face of the older part of the breakwater.

Peterhead.

The south breakwater for the harbour of refuge at Peterhead, begun in 1888, extends into a depth of 5 7f t. at low water (see HARBOURS) . For i,000ft. from the shore it was built as an upright wall on a rocky bottom, but the outer portion con sists of a superstructure wall of concrete blocks founded on a rubble base originally 3oft. below low water, increased after a storm in 1898 to 43 feet. The outer toe is protected by concrete blocks laid on the rubble mound. The northern breakwater at Peterhead (building 1928) is of the upright wall type on a rock foundation.

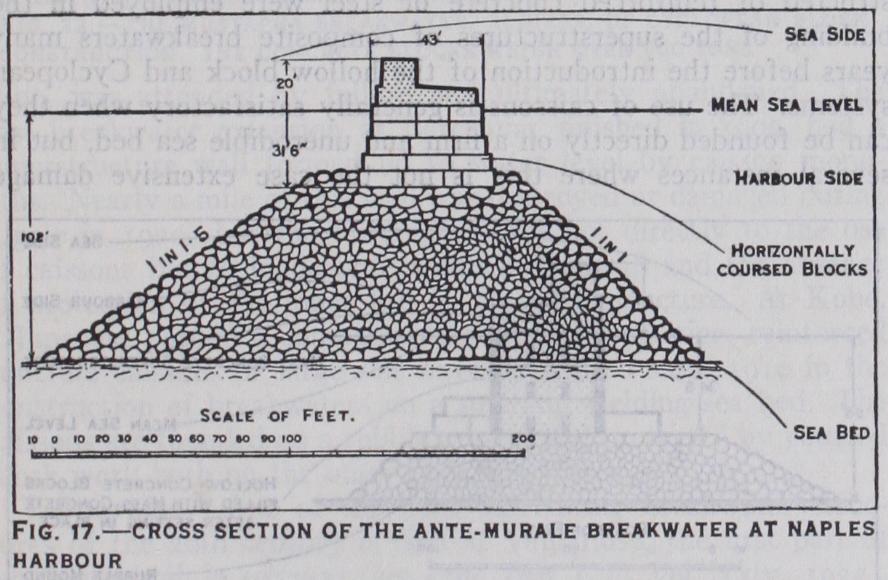

Naples.

The Ante-Murale breakwater at Naples (fig. 17) is a rubble mound in a depth which at the outer end exceeds i oo feet. The superstructure of horizontally coursed concrete blocks is founded 31 ft. below sea level and is capped by mass concrete. Here the sea bed is firm and comparatively non-yielding and special precautions were taken in building the rubble mound; consequently the structure has not suffered as a result of unequal settlement.

Sloping-block System.

A difficulty experienced in building a solid superstructure on the top of a rubble mound arises from the settlement of the mound which takes place when the weight of the wall comes on it. When the superstructure consists of hori zontal courses of masonry or concrete blocks, irregular settlement is likely to occur, resulting in dislocation of the joints and some times fracture of blocks. The sloping-block (or "sliced-block") system, in which the blocks form a series of sloping sections, laid at an angle to the horizontal usually from 67° to was devised to meet this difficulty. The blocks are free to settle, slice by slice, on the mound and are usually joggled together on the sliding faces by means of grooves in the blocks, filled by concrete in bags placed in position and rammed by divers, or by a groove and tenon moulded in the block faces (figs. 14 to 16, 18 to 20 and The settlement of the structure is sometimes accelerated by placing extra blocks temporarily on the top of the permanent blocks, thus increasing the load above the normal. Where a Titan crane is employed for setting the blocks, the weight of this assists settlement. The mass concrete capping on top of the blocks should never be constructed until settlement as far as can be assured has taken place.

Karachi.

The first superstructure built on the sloping block system was at Karachi. The blocks were laid at an inclination of 76° in two rows of three superimposed blocks and were entirely unconnected. Consequently the sea, forcing its way in a storm between the two vertical rows, overturned some of the 27-ton top blocks and threw them on to the rubble mound. In effecting the necessary repairs the top blocks were connected by stone dowels.

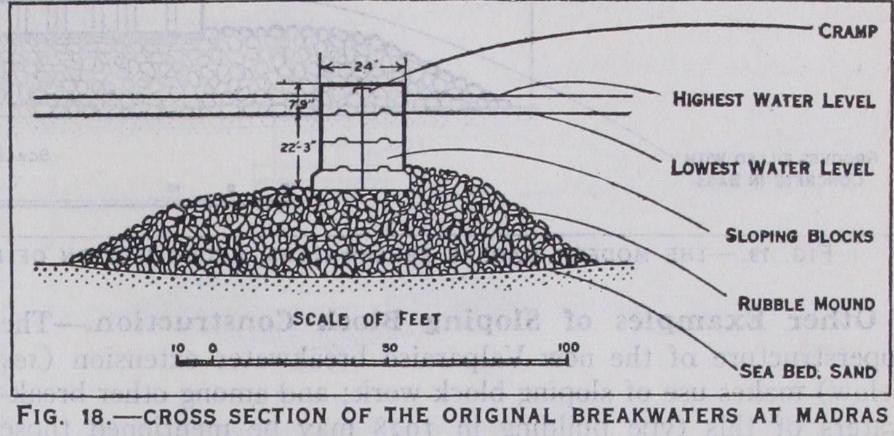

Madras.

The superstructures of the Madras breakwaters, commenced in 1877 (fig. 18), were of similar construction to that at Karachi; but the blocks in each row were connected by a mor tise and tenon joint with the blocks above it. The unconnected vertical joint between the two rows, however, led to the destruction of the greater part of the walls of the outer arms during a cyclone in 188i. In the subsequent reconstruction bond was introduced in the successive tiers of each sloping section and the upper blocks were cramped together. After settlement on the mound had ceased, a thick capping of mass concrete was laid on the top of the structure; and, finally, a mound of pell-mell concrete blocks was deposited on the rubble on the sea face of the wall to break the force of the waves and prevent undermining.The harbour at Madras is constructed in a position of extreme exposure and the works have suffered severe sea damage on many occasions. The original harbour entrance on the east side be tween the ends of the two curved breakwaters was closed in 191o, partly on account of the serious range in the harbour, due to the position of the entrance, and also because of the rapid silting which was taking place (see HARBOURS). A new entrance was con structed on the north side of the harbour protected by a shelter ing arm. This arm, as well as the new portion of the breakwater closing the old entrance, is of sloping block work on a rubble foundation protected by 3o-ton wave-breaker blocks on the sea face (fig. 19) . The outer portion of the sheltering arm was de stroyed during a cyclone in Nov. 1916 and has since been recon structed.

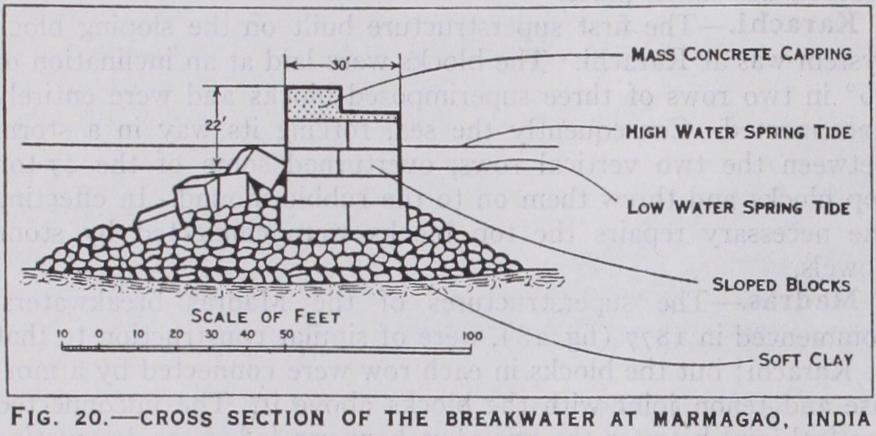

Marmagao.---The

breakwater at Marmagao, a Portuguese har bour on the west coast of India, commenced in 1884, is somewhat similar to the later work carried out at Madras. The mound in this case is formed on a soft clay bed readily compressible (fig.20).

Colombo.

At Colombo the superstructures of both the south west and north-west breakwaters were built on the sloping block system in sections 5-if t. thick at an angle of 68° (figs. 14 to 16). The blocks are bonded across each section and grooves are formed in the adjacent faces of the sections. The voids so formed were filled with concrete in bags after settlement on the mound had ceased. The same method of bonding and keying was adopted in the later work at Madras.Other Examples of Sloping Block Construction.—The superstructure of the new Valparaiso breakwater extension (see below) makes use of sloping block work; and among other break waters of this type building in 1928 may be mentioned those at Port Elizabeth and Antofagasta (Chile), and the extension of the Table bay breakwater. In the case of the last named the blocks are, however, laid direct upon the hard clay of the sea bed and not on a rubble mound.

Hollow-block Construction.

In the Granili breakwater at Naples, commenced in 191o, hollow concrete blocks each weighing under i oo tons, but measuring 3of t. X 162f t. X 7 zf t., were substi tuted for the smaller solid blocks used in the original work. The cavities in the blocks were filled with concrete deposited under water. The blocks being set one directly above another, five in height and in two rows, form separate piers free to settle inde pendently. The two rows of blocks make up a superstructure 6oft. wide. The capping of solid masonry and concrete work above water level is constructed in separate sections covering only two piers of blocks to enable the masonry to follow the settling movements of the blocks.The weak point of the hollow block system is the necessity of depositing unset concrete under water, always a difficulty and attended by uncertainty as to the quality of the concrete so treated. Apart from this possible source of weakness, the hollow block method of construction gets rid of the fear of displacement of solid concrete blocks set in horizontal bonded courses. It has been largely adopted in Italy, and to some extent in other coun tries, in situations of moderate exposure or where lengthy periods of calm weather can be looked for. At Genoa the Vittorio Ema nuele III. breakwater (fig. 21), built after the construction of the Granili breakwater at Naples, is of similar type; but larger hol low blocks, which weigh up to 23o tons and extend the full width of the wall, were employed.

Cyclopean Concrete Blocks.

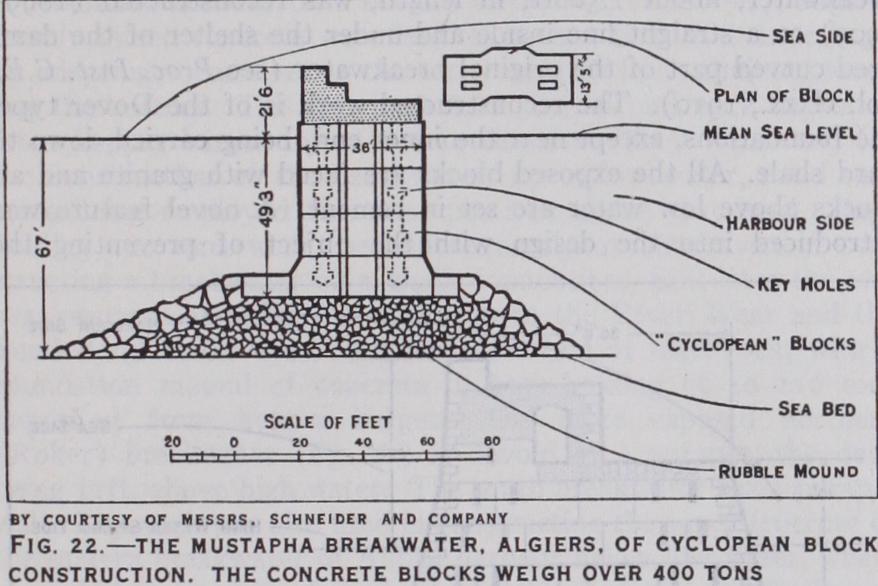

Following on their successful work with hollow blocks Italian engineers devised in 1923 a system of construction in which blocks of large dimensions, each extend ing the full width of the superstructure, are set to form pillars usually of three or four tiers in height. Blocks weighing from 200 tons to over 400 tons have been used in the building of break waters of this description, and for their handling floating lifting appliances have been devised which are of far greater capacity than any previously employed. The blocks, known as Cyclopean, are nearly solid, each having small cavities for convenience of lifting, which are ultimately filled with concrete (see Albertazzi and Cagli, Int. Congress of Navigation, 1926, Paper 36).The extension of the eastern jetty at Catania in Sicily is the first example of Cyclopean construction on a large scale, the blocks weighing 30o tons. Blocks of similar weight have been used in the new breakwater at Bari. The extensions of the Vittorio Emanuele III. breakwater and the Galliera mole at Genoa are (1928) being constructed with Cyclopean blocks. In these cases the weight of each block is restricted to 220 tons in order to make use of the existing floating cranes which had handled the earlier cellular blocks at that port. At Bengazi (Cirenaica) solid blocks, weighing 55o tons and constructed in a small dock, were floated into position by means of coupled pontoons between which a block, partly waterborne, was slung.

In the building of the Mustapha breakwater at Algiers, begun in 1927, blocks which weigh up to 418 tons are founded on a rubble mound at a depth of 49f t. (fig. 22), and are lifted and lowered into place by a floating portal crane of 450 tons lifting capacity mounted on two pontoons. The joint faces of the blocks are grooved and tenoned in the vertical planes.

Caisson Walls in Composite Breakwaters.

Caissons con structed of reinforced concrete or steel were employed in the building of the superstructures of composite breakwaters many years before the introduction of the hollow block and Cyclopean systems. The use of caissons is generally satisfactory when they can be founded directly on a firm and unerodible sea bed, but in several instances where this is not the case extensive damage has occurred. In any case it is a difficult matter to float, tow, sink and fill with concrete caissons of large dimensions.

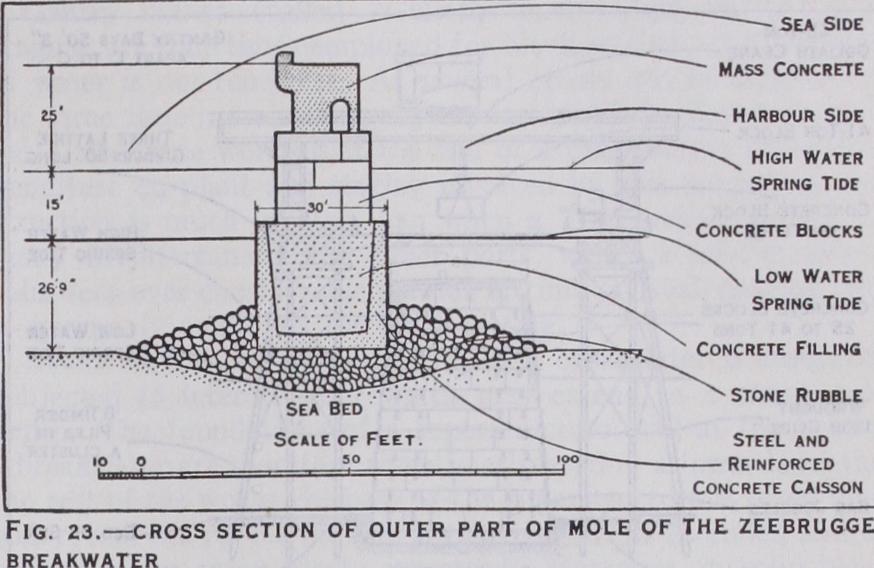

Bilbao.

The composite breakwater at Bilbao harbour at the mouth of the River Nervion, begun in 1888, has probably been one of the most difficult to construct on account of its great exposure to the Atlantic waves. The original design consisted of a wide rubble mound up to about i 6f t. below low water; a mound of concrete blocks up to low water; and a solid masonry super structure. The repeated damage to this wall by successive winter storms led (in 1895) to the abandonment of the original design and the construction, on a widened rubble base, of a superstruc ture protected to some extent by the outlying concrete block mound. The modified superstructure was formed of iron caissons partially filled with concrete which were floated out, sunk in position and filled up with concrete blocks and mass concrete. The caissons, which measured about 43ft. in width across the break water, 23ft. in length and 23ft. in height, weigh about 1,400 tons when filled. They form the base of a concrete wall founded at half tide level and carried up to 8f t. above high water. Although some difficulties have been brought about by the settlement of the rubble foundation, these have been overcome and the break water has successfully resisted the attacks of the heavy Atlantic rollers (see Churruca and the Port of Bilbao, Bilbao, 1910).Other Examples of Caisson Construction.—The mole of Zeebrugge (190o-09) (fig. 23), is an example of a breakwater, in a much less exposed situation than Bilbao, in the building of which caissons were used with not altogether satisfactory results, the work having suffered damage during construction. The cais sons, of steel and reinforced concrete, are founded on a rubble mound at various depths up to 4oft. below low water. The largest caissons are 1 oof t. long and 38f t. wide (see Memoires, Societe des Ingenieurs Civils de France, Dec. 1904). Reinforced con , crete caissons have also been used in building (1908-13) the two breakwaters at Bahia (Brazil), where the water is shallow and the position a sheltered one, and at Scheveningen in Holland. Their use in the construction of the Bizerta breakwater, begun in 1899, was attended by failure and ultimately abandoned. The east breakwater extension at Barcelona, finished in 1909, had a superstructure wall formed up to water level by caisson mono liths. Nearly a mile of this wall was destroyed or damaged during a gale in 1920; but the failure was due not directly to the use of caissons but to inadequate width in the wall and the absence of protection of the inner toe of the superstructure. At Kobe, a Japanese port in a comparatively sheltered position, reinforced concrete caissons of large size have been used since 1910 in the construction of breakwaters on a soft and yielding sea bed. The caissons are founded on a rubble mound and protected by coursed block work both on the outer and inner faces.

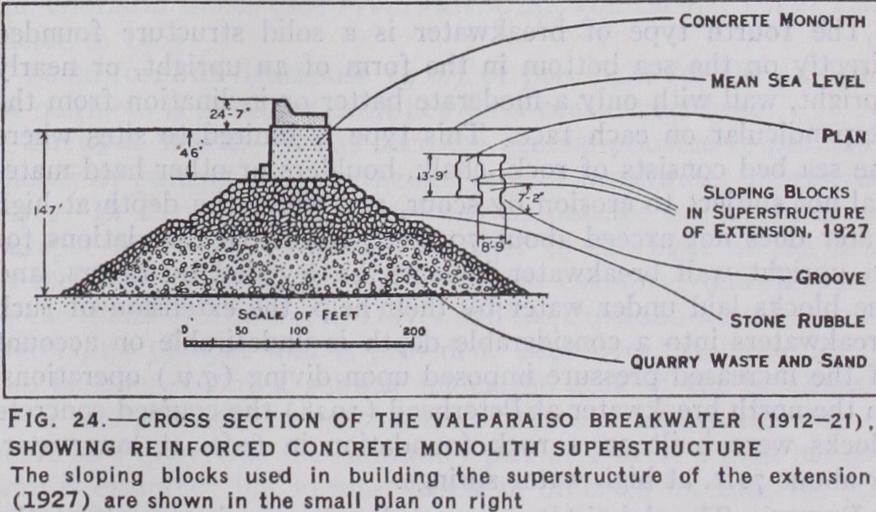

Valparaiso.—One of the most interesting breakwater struc tures of the loth century is that at Valparaiso, the first part of which was built in 1912-21 (see Proc. Inst. C.E., vol. ccxiv., 1922). The breakwater is of composite construction; the inner section, f t. in length, consisting of horizontal coursed concrete blocks set on a submerged rubble mound at a depth of loft. and por tected on the sea face by a pell-mell block wave-breaker of the Madras type (see above). The superstructure of the outer portion (fig. 24), 405ft. in length, consists of reinforced concrete caisson monoliths, which were floated over and sunk upon a rubble mound at 46f t. below mean level of the ocean. These monoliths are the largest which had been hitherto constructed in such a situa tion, each measuring 651ft. long, 521ft. wide at base and 49ft. in height, and were, after sinking, filled with mass concrete. The monoliths, as well as the blockwork of the inner section, are surmounted by a mass concrete superstructure and parapet wall. The outer portions of the breakwater were founded at a depth of over 'soft., on a comparatively soft sea bed of clay and mud. The depth in which the Valparaiso breakwater has been built is greater than obtains in the case of any other marine structure and it is fully exposed to the northerly gales of the Pacific ocean.

An extension of the breakwater, 2,30oft. in length, in an east erly direction across Valparaiso bay, in depths as much as 18of t. in places, was commenced in 1923 and was still under construction in 1928. For this extension sloping block work was substituted for caisson monoliths in the building of the superstructure, partly on account of the soft character of the sea bed in the silt of which it is estimated that the mound will sink considerably. The sloping blocks are joggled by pre-formed grooves and tenons on the sliding faces, and are surmounted by in situ concrete work as in the older structure. The lower part of the mound, up to a level of 66f t. below mean sea level, is of sand dredged by a powerful suction hopper dredger, and deposited on the sea bed, the flat slopes being protected by stone rubble.

Timber Cribwork.—The superstructures of composite break waters, built by the United States and the Canadian Governments in the Great Lakes, were often composed of timber cribs floated, like caissons, into position and sunk by filling them with rubble stone. The former cheapness of timber in those regions made this simple mode of construction economical in spite of the rapid decay of the timber. In the more modern examples the timber work is usually not carried higher than about aft. below water level, the upper parts being of concrete construction.

Suitability of Composite Breakwaters to Deep Water Conditions.—In view of the increased depth at which superstruc tures are now founded upon rubble mounds, causing the break waters to approximate more and more to the upright wall type, it might seem at first sight that the rubble base might be dispensed with and the superstructure founded directly on the sea bed. Two circumstances, however, still render the composite form of breakwater indispensable in certain cases : (1) the great depth into which breakwaters have sometimes to extend, reaching about 6oft. below low water at Peterhead, 117 f t. below mean sea level at Naples and even i8oft. at Valparaiso ; and (2) the necessity, where the sea bottom is soft or liable to be eroded by scour, of a wide base between it and the upright superstructure.

The injuries to which composite breakwaters appear to have been specially subject must be attributed primarily to the greater exposure and depth of the sites in which they have been frequently constructed as compared with rubble mounds or upright walls; but the direct cause of damage and even destruction has in many cases been the insufficient depth at which superstructures have been founded. Upright walls, indeed, are not well suited for erection in waters of great depth owing to the increased pressure of air under which divers have to work in laying blocks or preparing foundations. In the case of simple rubble mounds, the very large quantity of materials required for a high mound with flat slopes makes that type unsuited to such situations. The ample depth at which superstructures are now commonly founded; the due protection of the outer toe; the adoption of improved systems of block construction, such as the sloping block or the Cyclopean; adequate bonding and keying of the blocks; and the dispensing in many cases with a high sheltering wall, render modern superstruc tures as stable as upright wall breakwaters of similar height. Nevertheless, the conditions of exposure being equal, superstruc tures require generally greater base width than upright walls of the same height, because the greater depth of water in which such composite breakwaters are built exposes them to larger waves.

(4) UPRIGHT WALL BREAKWATERS The fourth type of breakwater is a solid structure founded directly on the sea bottom in the form of an upright, or nearly upright, wall with only a moderate batter or inclination from the perpendicular on each face. This type is limited to sites where the sea bed consists of rock, chalk, boulders or other hard mate rial not subject to erosion by scour, and where the depth at high water does not exceed about 7o feet. When the foundations for an upright wall breakwater have to be levelled by divers, and the blocks laid under water by their help, the extension of such breakwaters into a considerable depth is undesirable on account of the increased pressure imposed upon diving (q. v.) operations. In the north breakwater at Peterhead (1928) the coursed concrete blocks were built on a rock foundation in 6oft. at low water, or about 71 ft. at high water springs.

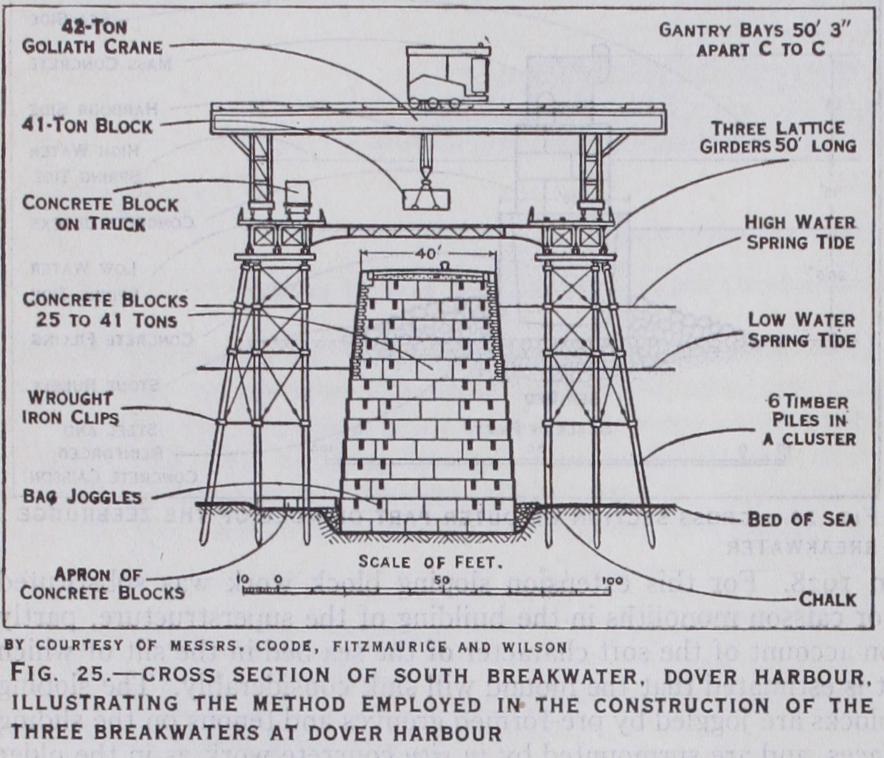

Dover.--The

Admiralty pier at Dover was begun about the middle of the 19th century and is an early and notable example of an upright wall breakwater resting upon a hard chalk bottom. It was subsequently extended in connection with the works for forming a closed naval harbour at Dover, which works included the construction of an eastern breakwater and a detached south breakwater (see Proc. Inst. C.E., vol. ccix., 1921). These are founded on a bottom, carried down to the hard chalk underlying the surface layer, levelled by men in diving-bells. The break waters are built of concrete blocks in bonded courses (fig. 25), the outer blocks above low water being faced with granite masonry. The face blocks are joggled together, and above low water the blockwork is set in cement mortar and the vertical joints grouted up. The blocks were laid by Goliath travelling cranes running on temporary staging supported by clusters of timber piles driven into the chalk bottom. Four Goliaths on each staging were used for excavating, preparing foundations with diving-bells and block-setting.The deepest foundation is 53ft. below low water springs. The rise of tide at springs being 18 a f the average depth is thus approximately 66f t. at high tide, necessitating a pressure of about 3o lb. on the square inch, which is near the limit at which divers can work continuously, without injurious effects, in diving bells. The detached southern breakwater has a flush deck, but the Ad miralty pier and the eastern breakwater have parapet walls. All the breakwaters are protected from scour along their outer toe by an apron of concrete blocks.

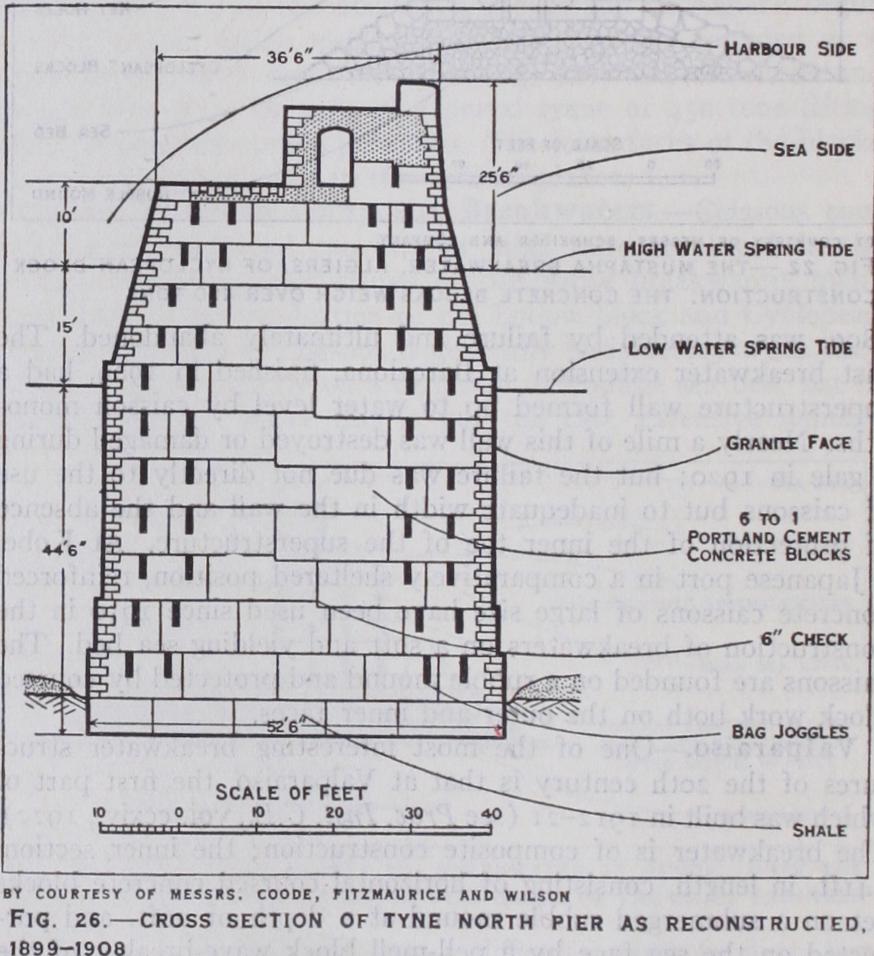

Tyne Piers.

The two breakwaters at the mouth of the River Tyne were originally commenced, about the middle of the 19th century, as composite breakwaters, the foundation level of the superstructure being placed at varying depths from near low water down to about 2 7f t. below low water in the case of the north pier. Towards the end of the century the north pier was severely damaged and breached as a result of the undermining of the foundation of the superstructure, brought about by the degradation of the rubble mound. The outer portion of this breakwater, about i,5ooft. in length, was reconstructed (1899 19o9) on a straight line inside and under the shelter of the dam aged curved part of the original breakwater (see Proc. Inst. C.E., vol. clxxx., 191o). The reconstructed work is of the Dover type, the foundations, except near the inner end, being carried down to hard shale. All the exposed blocks are faced with granite and all blocks above low water are set in cement. A novel feature was introduced into the design with the object of preventing the sliding of one course of blocks over the course immediately below it ; a check 6in. high, extending practically from end to end of the work, being provided in each course of blocks below low water (fig. 26).

Granite-faced Blocks.--It may be mentioned here that the use of granite masonry facing for concrete blocks in breakwater construction is unusual in modern work. The improvements which have been effected in concrete construction, its reliability when properly carried out and the impermeability of sound, well made concrete, have resulted in the gradual abandonment of masonry construction in favour of the more economical concrete. In some French ports large blocks are still made of a rough masonry consisting of rubble stone set in a concrete matrix and forming a sort of coarse conglomerate. Where the local conditions as to materials are favourable this form of construction is very economical.

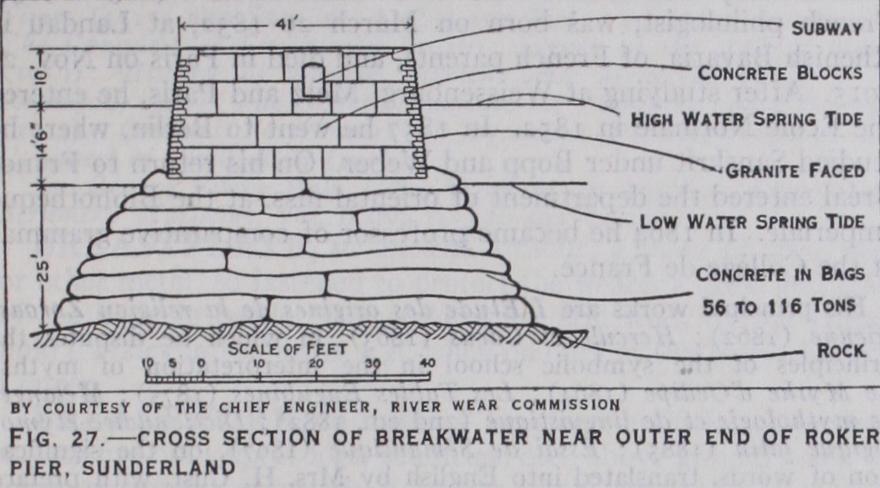

Concrete-bag Foundations.—The levelling of the founda tions for an upright wall breakwater is costly and tedious, even in chalk; and the expense and delay are enhanced where the bottom is hard rock. In constructing two breakwaters at the entrance to Aberdeen harbour on a bottom of granite, in 187o-77, bags of freshly mixed concrete were laid on the sea bed; and these bags, by adapting themselves to the rocky irregularities, obviated level ling the bottom. The bags each held 5o tons and were deposited from hopper barges towed out to the site. They were used for the construction of the breakwaters up to low water, mass con crete being employed for those portions above that level. Bags holding zoo tons were used subsequently at Newhaven in con structing a breakwater on a chalk foundation. Still later the two breakwaters sheltering the approach to the River Wear and the Sunderland docks were built, on a sea bed of marl rock, with a foundation mound of concrete in bags holding 56 to 116 tons deposited from hopper barges. The more exposed northern (Roker) breakwater (fig. 27) is devoid of a parapet, the deck being lift. above high water. The south breakwater has a parapet wall. Bag work was also used in constructing the superstructure of the eastern breakwater of Bilbao harbour below low water, where the rubble mound is of moderate height ; but this application of the system appears less satisfactory, as settlement of the super structure on the mound would produce cracks in the set concrete of the bags.

Caisson Monoliths.—Caisson monoliths have also been used in constructing the foundations of upright wall breakwaters, and some of the Heligoland moles, demolished after the World War, were built on this system (see Proc. Inst. C.E., vol. 220, 1926). Caissons, sunk by means of compressed air through the over lying sand and gravel into a foundation of hard chalk, were em ployed in constructing the lower portions of the vertical walls of the breakwaters at Dieppe where the tidal range is Soft. at springs.

Block-setting Cranes.—The blocks used in breakwater con struction are often laid in place by overhanging, block-setting cranes, called "Titans," which travel along the completed portion of the breakwater and deposit the blocks in advance on the mound levelled by divers. The cantilever superstructure of the Titan crane is supported centrally on a ring of rollers, set on the top of the travelling pedestal or portal, so that it can revolve and pick up blocks from behind the crane and deposit them at the side of the breakwater as well as in advance of the finished work (fig. 9). The large Titan at Peterhead deposits 50-ton blocks at a maximum radius of 1 oof t. ; that used at Fishguard had a radius of 125 feet. Titans are generally preferred for block setting by British engineers and have the important advantage, in exposed situations, that they can be moved back into shelter in stormy weather. The weight of the Titan also contributes to the con solidation of the rubble mound. When a Titan crane has been used in the building of a breakwater it should be retained, on the com pletion of the work, in some convenient position, as well as per manent rails for its travel along the breakwater. The crane is then available for use if repairs have to be carried out involving the lifting of large blocks. Such maintenance work must always be anticipated in the case of breakwaters of the mound and composite types.

Gantry cranes (called "Goliaths") travelling on temporary staging, are sometimes employed for block setting when the depth of water is not too great. As several cranes can be employed at the same time more rapid progress can be made than with a sin gle Titan crane working at the end of a breakwater; but the ex penditure on plant and staging involved by this method of con struction is much greater than when a Titan crane is used. At many Mediterranean and other ports, where a continuance of calm seas over considerable periods of time is usual, floating plant is commonly employed for block setting.

Breakwater Heads.—The end of a breakwater is frequently subjected to intense scour which may extend to a considerable depth. The foundations of a superstructure wall at the head of a breakwater are therefore sometimes placed at a lower level than the rest of the work; the base of the superstructure is often made wider; and the rubble mound, if there be one, is extended and the protection by apron blocks increased. Moreover, in solid block work construction some special means must be adopted to finish off and protect the concrete blocks where the ordinary section of the work terminates.

Various methods have been adopted for the construction of the heads of breakwaters. In some cases large steel caissons, circular or rectangular in plan, have been sunk on or into the sea bed or mound to form a foundation brought up above water level and afterwards filled with concrete blockwork or mass concrete. The blockwork of the main portion of the breakwater is subsequently built up to, and makes junction with, the caisson head. The head of the Colombo south-west breakwater is an early instance of a steel caisson founded on a rubble mound; and a circular steel cais son sunk to below sea-bed level was used for the head of the north sheltering arm at Madras (see Proc. Inst. C.E., Selected papers, 1926). In other instances reinforced concrete caissons have been employed instead of steel caissons. Where caissons are not used the end of the breakwater is often built of specially con structed and keyed blocks in the form of a roundhead or some other enlargement of the normal section. This plan is commonly adopted in the construction of upright wall breakwaters on firm foundations such as the Dover breakwaters and the north pier at Tynemouth described in the preceding section. It has also been the Gibraltar moles (see Proc. Inst. C.E., vol. cxcvii., 1914) com pleted in 1905.

Some form of lighthouse (q.v.) or port light for the guidance of mariners is usually established on a breakwater head.

Parapet Walls.—It has been the general practice to provide a shelter or parapet wall on the sea face of breakwater superstruc tures. In many cases a tunnel-way or passage is formed in the parapet for access in stormy weather to the light at the head of the breakwater. In several important examples, however, such as the island breakwater at Dover and the Colombo western break waters, no parapet wall is provided. Moreover, sheltered access can be provided by a subway under the deck of the breakwater as at Sunderland. In special cases where a breakwater has to serve as a quay, like the Admiralty pier at Dover, a high parapet wall is essential; but in most cases, in order to increase the sta bility of the structure, it would seem advisable to keep the para pet very low or to dispense with it altogether. This course is par ticularly expedient in very exposed sites, as a high parapet intensi fies the shock of the waves against a breakwater and their erosive recoil.

Small Breakwaters.

The breakwaters and protective piers which are constructed at small harbours such as fishery harbours and ports of secondary importance are frequently built in com paratively shallow water and sheltered positions. In their con struction the principles which have been set out in the foregoing paragraphs are applicable, mutatis mutandis. Many small upright wall breakwaters have been constructed in a moderate depth of water on a hard bottom of rock, chalk or boulders, by erecting timber framing in suitable lengths, lining it inside with jute cloth and then depositing concrete below low water in closed hopper skips. The portion of the breakwater above low water is then raised by tide work with mass concrete or masonry.A form of breakwater, frequently adopted in past times for comparatively sheltered positions in no great depth of water where the sea bed consisted of sand or other soft material, is the cribwork pier. This type of structure was commonly formed of two rows of timber piles driven in the sea bed and connected to gether by ties or bracing, to which were fixed horizontal timber runners with spaces between them. The crib so formed was filled in with large stone rubble.

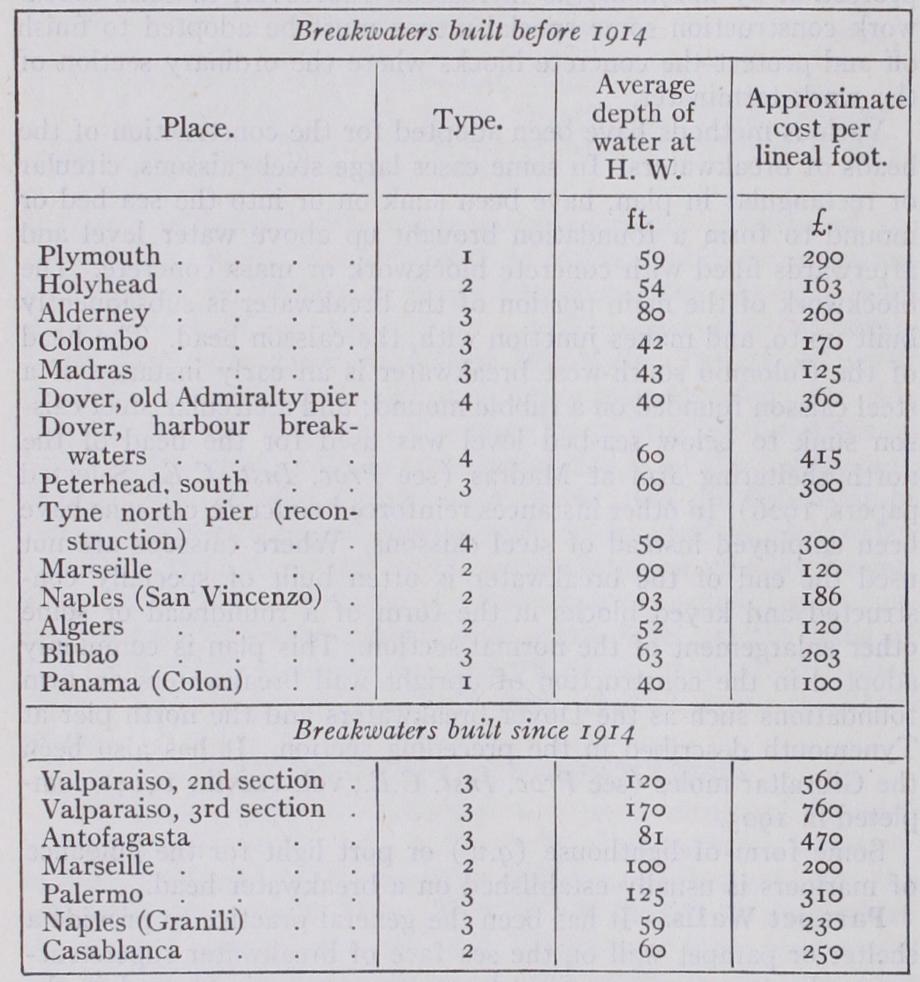

Cost of Breakwaters.

The expense involved in the construc tion of breakwaters varies within wide limits. The degree of expo sure of the site ; the depth of water ; the facilities for obtaining materials and labour and their cost, vary so much in different cases as to make comparison fallacious. The following figures of the average cost per lineal foot of typical breakwaters illustrate the wide variation. It should be noted that from 50% to l00% must be added to pre-war cost figures to make them comparable with post-war conditions.

Time Occupied in Building Breakwaters.

The construc tion of most of the breakwaters described in this article has occu pied many years; sometimes twenty and even thirty or forty years. An advance of 15o or goof t. in the course of a season's work is often regarded as satisfactory. Generally speaking an increase in the rate of building involves a larger expenditure for a given length of structure.BIBLIOGRAPHY.-For general principles of design and descriptions Bibliography.-For general principles of design and descriptions of 19th century construction see L. F. Vernon-Harcourt, Harbours and Docks (2 vols. Oxford, 1885) ; T. Stevenson, The Design and Construction of Harbours (1886) ; W. Shield, Harbour Construction (1895) ; Quinette de Rochemont, Cours de Travaux Maritimes (3 vols. 1900) ; C. de Cordemoy, Les Ports Modernes (2 vols. 1900) ; and, particularly for Italian breakwaters, Ports Maritimes de l'Italie (Milan, 1905 ; French and Italian eds.) . G. de Joly and C. Laroche, Travaux Maritimes, vols. i. and ii. (1921-22), is a good modern work. Brysson Cunningham, Harbour Engineering (3rd ed., 1928), also contains references to more recent work. The writings of Smeaton, Telford and Sir John Rennie are of great historical interest in connection with early construction. The Proceedings of the International Navigation Congresses include many important papers on breakwater design and construction, especially those of the congresses at Milan (loth, 1905), Philadelphia (12th, 19i 2) and Cairo (14th, 1926) . A good and well illustrated description in English of earlier Italian breakwaters is L. Luiggi's Recent Breakwaters in Italy (Int. Maritime Congress, London, 1893) . E. Quellennec's Memoir (I. N. C., Cairo, 1926) is an excellent resume of modern Continental practice. Complete biblio graphic lists are issued periodically (since 5908) by the International Association of Navigation Congresses, Brussels. See also Proceedings Inst. C.E. and Memoires, Societe des Ingenieurs Civils de France. • (N. G. G.)