Canning

CANNING is the method of preserving fresh foods by steril izing them in hermetically sealed containers. The form, colour and quality of food after the process is practically the same as that of the product in its fresh state. No added substance or chemical need be used. Heat adequate to kill the bacteria which cause fermentation and decay is sufficient.

Primitive canning was originated by Appert, a Paris chef, 1783 95, though its scientific basis was not understood until the results of Pasteur's work on fermentation were first employed in 1895 by Russell at the University of Wisconsin, and by Prof. S. C. Pres cott of the Massachusetts Institute of Technology, the latter work ing in collaboration with William S. Underwood. Appert's method consisted in placing the sealed bottles containing the food in a water bath and bringing the water to the boiling point. This original principle and method of food preservation differs from that of to-day only in the amount of heat and the manner of applying it, though Appert himself came to realize that greater heat than he was able to develop was necessary. But until canners believed almost entirely in the fallacious theory that pre servation was due to the exclusion of air from the container.

Science is being more and more intensively applied in the indus try, and to-day canning has become a scientifically controlled in dustry. This result has been brought about through co-operation of the industry laboratories of the Canning Associations and of the Government and the universities. Surveys and intensive studies have been made of the bacterial flora associated with food. Ther mal death points; i.e. the time temperature treatments of bacteria, have been accurately determined by the use of thermocouples which measure the rate of heat penetration into various foods in all sizes of containers during the sterilizing treatment. Knowledge of canning was brought to America from England about 1818, though very little progress was made in the industry until after 186o. Since that date the United States has become the greatest producer and consumer of canned foods in the world.

Development of the machinery of the modern cannery was slow. Practically all equipment up to 187o was crude, cumbersome and inefficient. The first important improvement was the heavy closed retort or autoclave, which made possible the higher temperatures needed for sterilization. This device was the invention of Appert's son, who also used a thermometer in the autoclave to enable the maintenance of a constant temperature. The adoption of steam under pressure finally placed the canning industry on a more definite but not, strictly speaking, scientific basis.

Canning Vegetables and Fruits.

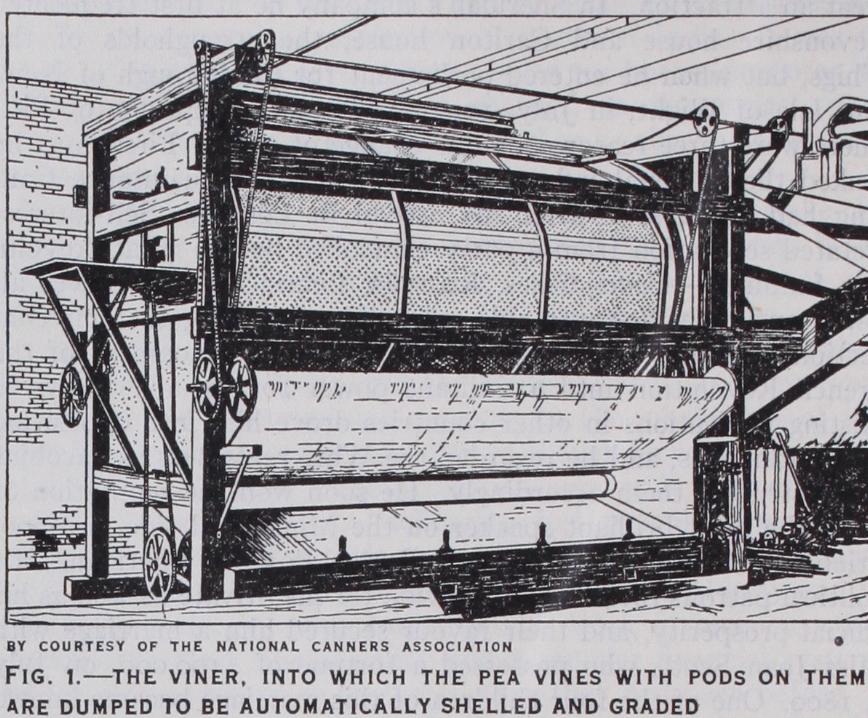

Each variety of fruit, vegetable, meat and fish is prepared in a manner best suited to its particular type, yet the process is more or less uniform. Peas, the most delicate in flavour of all garden crops, must be picked when their tenderness and flavour are at their best. Furthermore, they must be in cans within a few hours from the time they are harvested. It would be impossible to secure sufficient labour to pick the peas from the vines, so the vines with the peas on them are mowed, as are hay and wheat, and immediately trucked to the factory where they are dumped in a "viner" (fig. 1) . This ma chine consists of a Iarge cylinder in which paddles revolve at a speed sufficient to open the pods. Each machine replaces the labour of 500 pea pickers in the field and 500 "podders" or "shell ers" at the factory. As the peas come from the viner, they arg automatically graded for sizes, then pass through a cleaner, which extracts broken pods, stems and "splits"; and then are washed in fresh hot water, a procedure known technically as "blanching." After "blanching" they go to the machines where they are auto matically placed in cans with a measured quantity of seasoning brine. The can tops are next automatically placed in position and sealed by a closing machine ; they then go to the "cooker." After cooking they are cooled quickly. Over-cooking has a tendency to impair the quality of the product and this is prevented by cooling, immediately after the cooking in the retort is completed.

Tomatoes are picked by hand, and on delivery at the factory, are given two thorough washings, scalded and peeled, and placed in cans either by automatic machines or by hand. Corn is hardly touched by hands after its arrival at the factory where it is husked, cut from the cob, conveyed to cookers and filled into cans for final processing—all by automatic machinery. Of the less impor tant vegetables asparagus stands out as the most intensively culti vated for canning. While there is a very limited packing of asparagus in several States, California canners practically monopo lize the industry in this particular item. The handling of asparagus is practically all manual operations. Fruits go through the clean ing and washing processes. They are then treated in accordance with their individual characteristics; e.g., cherries are pitted; peaches are peeled by special processes; pears are generally peeled by hand; apples are pared, cored and sliced by machinery; and each of the products is then cooked at temperatures adjusted to the sterilization needed by that particular fruit.

Canning Milk.

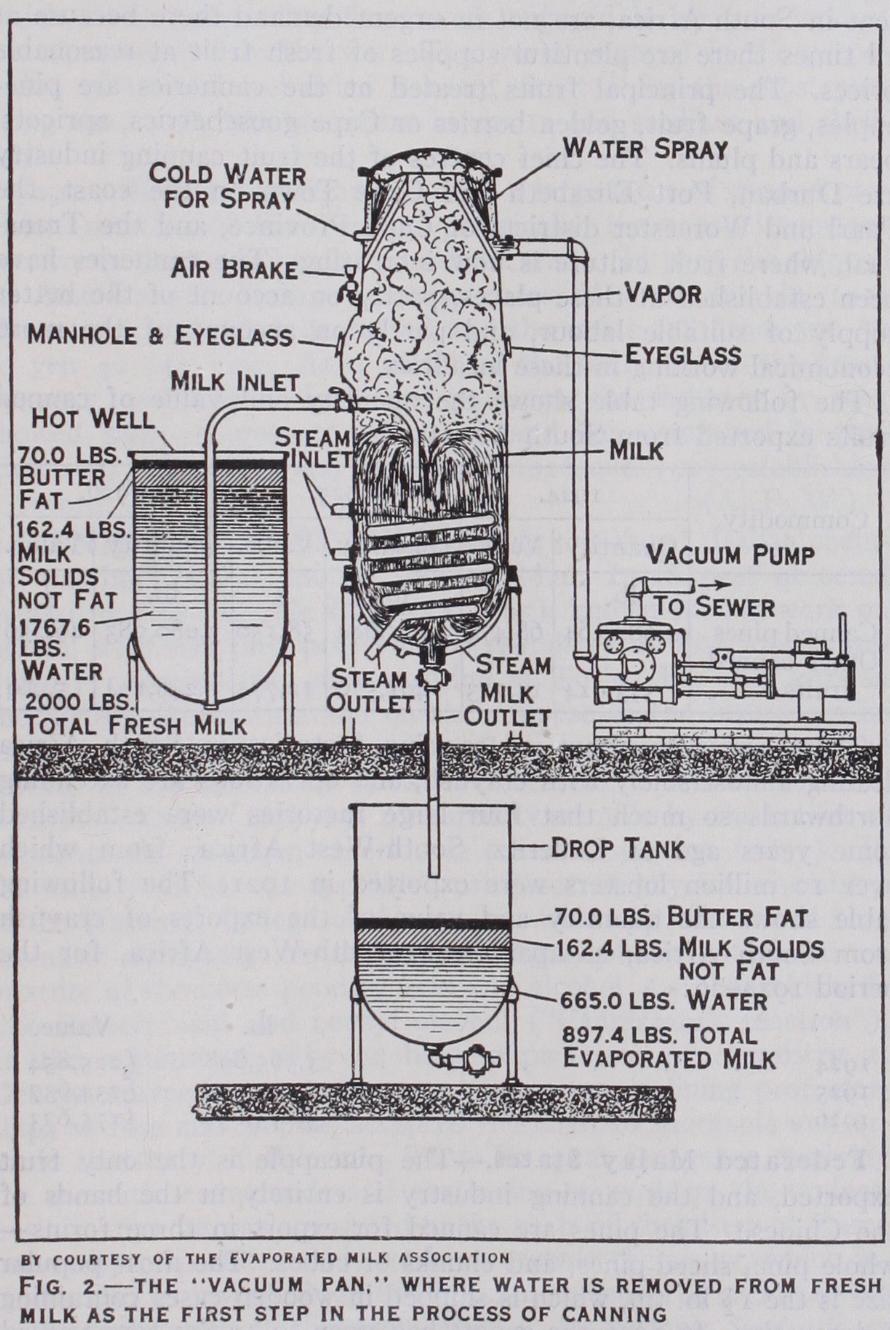

The first attempts to can condensed milk were made by Gail Borden at Torrington, Conn., in 1856, though he never operated his small plant commercially at this place, as funds were lacking. The first commercial condensed milk was canned the following year by Borden at Burrville, Conn., sugar being used as an added preservative. The Civil War gave the necessary impetus to establish the condensed milk industry. Many efforts were made to can milk without the aid of sugar. The first evaporated (unsweetened) milk successfully produced was at Highland, Ill., by the Helvetia Milk Condensing company, who finally succeeded in commercializing their product in 189o.In general, the process of canning milk is as follows : evaporation of the water is brought about in a "vacuum pan" (fig. 2) . This is a closed metal container, to which heat is applied by means of a steam jacket and steam coils. If the air is exhausted, the milk boils at a temperature of about 14o° F. There is, therefore, little exposure of the milk to heat. When the removal of about 4o% of the water has been effected, the concentrated milk is forced through apertures (fig. 3) so small that the fat globules are finely divided. The purpose of this process is to render the fat globules so small that they will not use to the surface of the evaporated milk in the form of cream. The chemist now tests the milk to make sure of compliance with the Government standard and the next step is the filling of the cans. Ordinarily, the "vent hole" type of can is used. In this type the can manufacturer leaves a small opening in the centre of one end, and through this opening the evaporated milk is introduced by means of a small nipple. After filling, the hole is sealed with a drop of solder and the can is ready for the sterilizer.

Products Used in Canning.

It is estimated that more than i,5oo,000ac. of land in the United States are utilized in raising the various crops which find their way into cans or glass. In addition to this is the area used for grazing cattle and other animals, the edible portions of which, including milk, also go into canned food. Salmon, sardines, oysters, tuna fish, mackerel, shrimp, lobster, anchovies, codfish and other marine and fresh water products are likewise important items in the list of canned goods. Vegetables and fruits in any climate and all kinds of fish, fowl, game and meats, may be preserved for future use through canning. Canning on a commercial scale is carried on in regions where soil and cli mate conditions are the most favourable for securing an average volume of a superior quality crop. Transport charges, while always of importance, do not necessarily operate against the merchandising of canned food no matter how remote the factories may be from the large distribu tive markets of the country. As an illustration : Pacific coast fruits dominate the canned fruit sales of the Atlantic coast not withstanding the fact that there are canneries packing excellent fruit more than 2,000 m. nearer this market.Vegetables show a wider lati tude of location possibilities, yet here, too, certain sections domi nate. Practically every vegetable may be found in cans, yet the im portant staples are corn, tomatoes and peas. Wisconsin, New York and Utah canneries are charac terized both by the quality and quantity of their peas. In corn, Maine, New York, Ohio, Indiana, Illinois, Iowa and Minnesota are the leading producers. Tomato canning is specialized in the States of Maryland, New Jersey, Delaware, Virginia, Indiana, Mis souri and Utah.

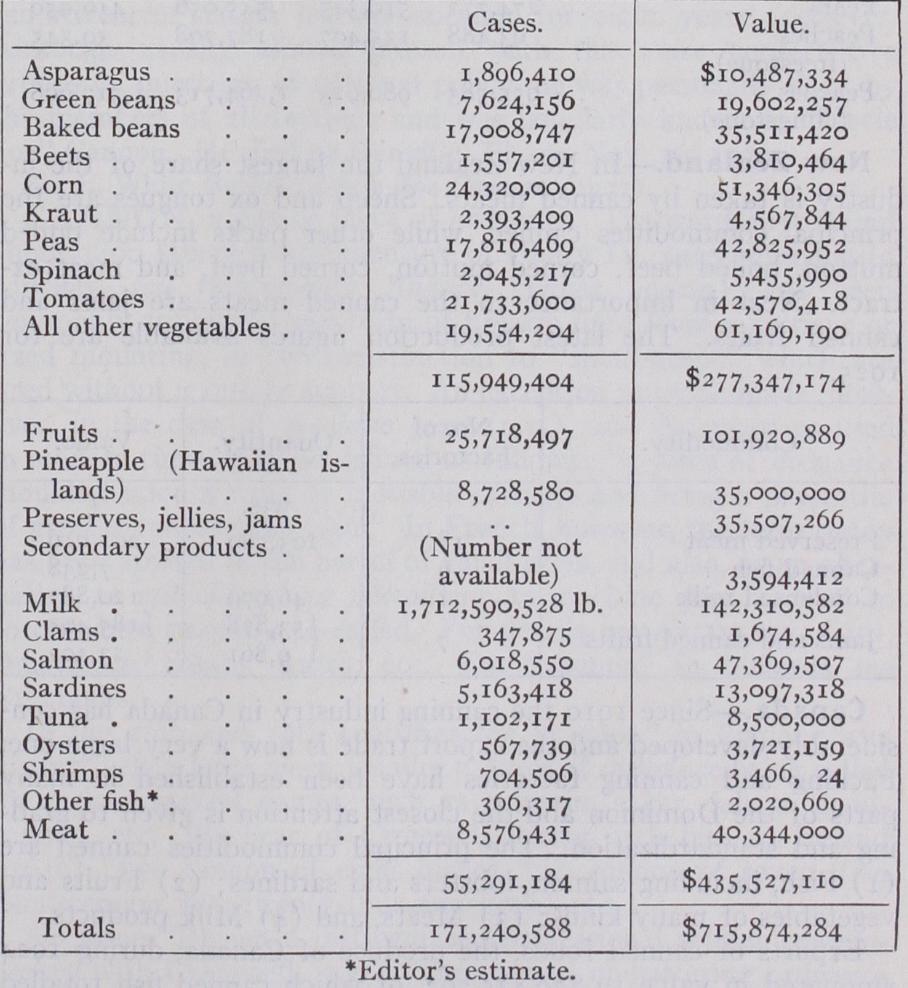

The figures given in the following table are based on the United States Government census report of 1925, revised from later sources: There have been frequent charges that consumers of canned food are liable to "ptomaine poisoning." Such charges are un founded. Sterilized food in air-tight containers cannot under any circumstances be dangerous. No case of poisoning has ever occurred from eating properly sterilized and sealed canned food.

Great Britain.—The canning industry was of considerable im portance in Great Britain before 1914, and a large export trade in canned meats, fish and vegetables had been developed. War demands gave a great impetus to the industry, particularly in the production of canned "rations," hams, etc., for the British and Belgian armies. The export trade, however, was greatly reduced, but it quickly revived after the war and to-day is an important factor in the trade of the country. The National Food Canning Council was set up in 1925 in order to promote the organization of food canning, and so increase the quantity and consumption of home-grown produce. This led to a great revival of the industry, and factories provided with the most up-to-date labour-saving American machinery, were established at Wisbech, Hereford, Evesham, and in Kent, chiefly for fruit and vegetable canning. These new ventures in Great Britain are proving most profitable to the grower, to the South Wales tinplate industry, to the work ers in the canning factories, and to the consumer, who can now obtain a larger variety of fruit and vegetables. As an instance of the expansion of the industry, at the Wisbech factory the output in 1925 was about i,000,000 cans, whereas in 1927 it was 7,000,00o cans. Other factories have shown equal progress.

Australia.—Here 2 7 6,000ac. are under fruit trees, an increase during the last ten years of 85,455 acres. The industry employs 27,900 field hands and 5,000 factory hands. The following table shows the number of dozen tins of output : 1922-23. 1923-24. 1924-25. Apricots . . . 245,244 275,350 Pears . . . Peaches 39,345 (freestone) Peaches . (clingstone) New Zealand.—In New Zealand the largest share of the in dustry is taken by canned meats. Sheep and ox tongues are the principal commodities canned, while other packs include boiled mutton, boiled beef, corned mutton, corned beef, and meat ex tract. Next in importance to the canned meats are jams and canned fruits. The latest production figures available are for 1925.

Canada.--Since 1910 the canning industry in Canada has con siderably developed and the export trade is now a very large one. Packing and canning factories have been established in many parts of the Dominion and the closest attention is given to grad ing and standardization. The principal commodities canned are (I) Fish, including salmon, lobsters and sardines; (2) Fruits and vegetables of many kinds; (3) Meats, and (4) Milk products.

Exports of canned foods, the produce of Canada, during 1924 amounted in value to of which canned fish totalled and condensed milk Sardine canning is confined almost wholly to the province of New Brunswick. The name sardine is misleading, as the fish used in the canneries of New Brunswick are the young of the herring. The first mention of a sardine industry in Canada dates back to some time in the late '6os. Although but three canneries were reported in 1924, with a total pack of 282,306 cases and of $810,574, the importance of the industry to New Brunswick is explained by the fact that the factories of Maine, U.S.A., about 5o in num ber, depend almost wholly on the supplies of fish obtained from Canadian waters.

The canning of fruits and vegetables is carried on most ex tensively in the provinces of Ontario, British Columbia and Que bec. The vegetables canned include tomatoes, peas, corn, beans, beets, carrots, pumpkin, squash, spinach and asparagus.

The canning of meats is a branch of the great meat-packing in dustry and is not so extensively carried on in Canada as are other sections of the canned foods group of industries, being more in the nature of a side line of the main industry. The total value of canned meats manufactured in Canada during the year 1924 was $840,192. The value of condensed milk produced in Canada as first reported in the decennial census of 1891 was $83,000. In 1901 the value had increased to $269,520, in 1906 to whilst in 1925 it had reached $53,453,472.

South Africa.—The industry in South Africa, though of com paratively recent establishment, is nevertheless of considerable importance owing to the increased cultivation of fruits for the export market. Canned fruits, though consumed to a great ex tent in South Africa, are not in urgent demand there because at all times there are plentiful supplies of fresh fruit at reasonable prices. The principal fruits treated at the canneries are pine apples, grape fruit, golden berries or Cape gooseberries, apricots, pears and plums. The chief centres of the fruit canning industry are Durban, Port Elizabeth and Cape Town on the coast, the Paarl and Worcester districts of Cape Province, and the Trans vaal, where fruit culture is now increasing. The canneries have been established at these places, partly on account of the better supply of suitable labour, and partly on account of the more economical working in these localities.

The following table shows the quantity and value of canned fruits exported from South Africa: There are now about 20 canning factories in South Africa dealing almost solely with crayfish, and operations are extending northwards so much that four large factories were established some years ago at Luderitz, South-West Africa, from which over 12 million lobsters were exported in 1921. The following table shows the quantity and value of the exports of crayfish from South Africa, as apart from South-West Africa, for the period 1924-26: lb. Value.

1924 . . . . 1925 . . . . . . 1926 . . . . . . 3, Federated Malay States.—The pineapple is the only fruit exported, and the canning industry is entirely in the hands of the Chinese. The pines are canned for export in three forms— whole pine, sliced pines, and chunks or cubes. The most popular size is the I Z lb. tin, which is shipped in wooden cases containing 4 dozen tins. In 1926 the export had risen to 40,633 tons valued at £894,808. In 1927 over 8o% of the total import of canned pineapples into the United Kingdom came from Malaya.

In Italy, where the canning industry is firmly established, the export of canned fruit and vegetables, particularly tomatoes and cherries, has shown a steady increase, the general standardiza tion, packing and canning being most efficient. Since the World War, France, which has many canning establishments and ex ports a large quantity of sardines, vegetables and preserved fruits, has practically re-established her trade and regained her lost markets. Norway's canned fish and meat industry is of great importance to the country. Since 1895, the fish-canning trade has expanded at an exceptionally rapid rate, and Norway is now one of the leading exporters of canned fish. This expansion is clearly instanced in the exports of brisling and sild, the main products of the industry, which are about 22,000,000 kegs yearly. Norway has over 200 canneries, employing some 6,500 hands. The total weight of canned goods exported in 1925 was 40,240 metric tons, of which 28,202 tons were smoked sardines, 5,061 tons unsmoked sardines and 5,389 tons kippers. Canning machinery is exported from Norway to other countries engaged in the industry.

Spain, Portugal and Siberia are all engaged in the canned sardine or salmon industry, the quantity and value exported from these countries in 1926 showing a large increase. Spain and Portugal also devote considerable attention to canned fruits, the exports of which are increasing. In Belgium the canning industry rapidly developed after I910. The oldest and the most flourishing branch is that of canned vegetables. The manufacture of canned fruits on a very large scale has been developed largely in co operation with British firms. An industry which has made great strides is the manufacture of canned and crystallized fruit, in which 22 manufacturing firms were engaged in 1925 as against less than ten before the war. The works engaged in the prepa ration of canned and dried fish are situated for the most part along the coast, and specialize in sprats and sardines and shell fish.

Japan, through the organization of a large trust of canned pro vision merchants, has become practically the most important country in the canned crab and salmon trade. In 1923 she shipped to America and Europe 220,000 cases of crab, but in 1924 the output somewhat decreased and the value fell from yen 5o to yen 4o per case. As a result of the influence of the trust, however, and also of improved packings, the industry in 1925 showed signs of greater expansion, and has continued in that direction, the output and exports in 1926 and 1927 establishing a record. (A. F. W.)