Chain Manufacture

CHAIN MANUFACTURE is the fabrication of a series of links, usually of metal, which are joined together by one of several methods. A chain provides a flexible loop or a connection between objects. The metal of the link is sometimes twisted to form a knot, or welded to strengthen the connection. Many methods of manufacturing chain by hand and machinery are now in vogue. Although a small quantity of chain is used for holding prisoners in check, the bulk of it serves man in various phases of his daily life. On the sea it is used for huge ship anchor chains, deck lashing chains, steering gear chains, buoy chains, etc. Railways use safety chains, brake chains, conductor's valve chains, etc. For motor travel on wet and icy roadways, anti-skid chains are used. Likewise on the farm, in the mine, the forest, the shop or on any extensive engineering operation, usage is found for chain.

There are three general classifications of chain: welded, weld less and transmission, the latter being literally a weldless style. Various materials are used in the manufacture of chain. Precious metals and semi-precious stones are formed into chains for jewel lery and ornaments. Industrial chains are made from iron, steel, brass, bronze, nickel, aluminium and other metals or alloys. The large majority of commercial chain is made from wrought iron or steel. Wrought iron has had preference among fire-welded chain makers for many years. Wrought iron is generally regarded as the most reliable material in the manufacture of chains for uses where a failure would endanger life or property. It has considerable duc tility, weldability and rust resistance. However, many reliable chains are made from steel.

Workmanship.

Hand and machine-made chain links usually go through several processes before they are ready for assembling into chains. Exceptions are in the instances of links used in cast chain, knotted chains and chain made directly from the solid bar. These processes vary widely in the different types of chain. In hand-made chain, the first operation consists of cutting the bar into short sections to a predetermined length, governed by the size of the link to be made. This short section is flattened, usually called "scarfed," at each end and then bent into a U shape. The scarfed ends are then brought to a welding temperature, threaded through the last finished link, and the weld completed by hammer ing. To give the welded end a finished appearance, concave tools, called "dollies," are sometimes placed over the weld and by addi tional hammering on the dollies, the weld is smoothed and shaped. The heating material for the chain maker's furnace is either coke, oil or gas.By the use of machines some of these operations in this method are eliminated and others made easier. Bars or rods of metal are wound by machine into oval coils and single convolutions of the coils are cut on an angle of about thus furnishing single scarfed links ready for placing in the furnace to be heated. When the scarfed ends are at a welding temperature, the link is removed from the fire, threaded into the last completed link and the weld completed. Completion of the weld is accomplished with the aid of a hand hammer which is used to close the scarfed ends of the link together with a few blows. From this point the weld is com pleted in a power hammer, equipped with dies which fit over the welded end of the link. These hammers are operated by foot power, direct drive or indirect drive from some remote source of power. Chains made by this method have a slight twist in them. This twist is caused by the coiling operation. When the chain is for uses where this twist would be objectionable the twist is re moved in a power hammer having especially designed dies, which straighten each link immediately after it is welded.

Electric Welded Chain.—This is the latest development in, welded chain manufacture. A large part of the world's tonnage of small welded chain is now made by this method. Sizes up to in. diameter are commercially made in large quantities. Any of the larger sizes can be electrically welded but manufacturing costs in 1928 were too high. Three types of electric welds are in general use at the present time—the butt weld, the half-butt weld and the flash weld. All of these are of the resistance type, in which the electric current, passing through the material and across the butted ends of the link, produces sufficient heat to raise the metal to the welding or fusing temperature. A later development in electric chain welding is called "percussion welding," but it is not being used commercially. In this latter method, an electrically charged condenser is discharged across the butted ends of a chain link.

Links for electric welding are prepared differently than for fire welding. In the electric method, coils of wire or rods are passed through a chain-forming machine, which automatically straightens the wire, cuts the required length, threads the wire into the last completed link and forms the link, making a continuous chain ready for the welding machine. This butted chain is passed through a chain-welding machine which welds the links. Some welding machines weld alternate links and others consecutive links. They are automatic with one operator attending many machines, or semiautomatic, requiring the services of an operator for each machine. In the electric-weld process the weld is usually made at the side of the link. In the fire-weld process the weld is usually at the end of the link, the exception being certain very large sizes which are sometimes made with the weld at the side. Some electric welded chain is made with weld at the end of the link, but this is the exception, rather than the rule. In the upset-welding method the links are welded at a relatively low temperature and the butted ends pressed together by a relatively low pressure. This type of weld is characterized by the extruded metal at the weld, forming a bulge which is seldom trimmed off. The semi-upset welding method is similar to the full-upset, with the exception that when the weld is about to be completed a die is placed over one-half the diameter of the material at the butted portion. This die pre vents the metal from being forced to the outer side of the link.

Flash welding is also of the resistance type. It is distinguished by a small amount of metal extruded at the butted ends when the pressure is applied to form the weld. Because of the pressure and closeness of the electrodes, this excess metal, sometimes called the "flash," takes the shape of a flattened ring, differing in this respect from the bulge of the upset-weld. The "flash" is trimmed off close to the diameter of the material, leaving a smooth weld which, when polished, defies detection.

Welded chain is used largely in the straight link variety ; how ever, some use is also made of twisted links. This type has the links twisted so that each link will be in approximately the same plane and therefore lie flat. In the fire-weld method each link is twisted as completed, but in the electric process the completed chain is passed through a machine which automatically twists the links. Other chains which have the same general shape as the welded chains, yet are not welded, include cast chains, which are made by casting metal in properly shaped molds. and solid link chains, made by stamping a solid cuneiform bar into the shape of stiff chain and twisting the individual links apart to make it flexible. The result is a solid, link chain having the appearance of a welded chain.

Anchor Chain.—For ship anchors is used a chain with links having a bar, called a stud, across the inside width of each link. This is called "stud-link" chain and in marine circles is referred to as a chain cable. Both the forming and welding operations are similar to the open link fire-welded chain. After the open link is completed, the stud, concave at each end, is inserted in the link and the sides pressed together. A relatively small amount of stud link chain is made by a steam hammer process in which the link bars are upset ; i.e., balled on the end and scarfed by machines. The scarfed ends are heated and the weld completed on a steam hammer. In cast steel chain the stud is cast at the same time as the balance of the link and becomes a solid part of the link. Studs used in wrought iron chain are either castings or drop forgings. There are several reasons for putting the stud in this type of chain. It prevents the chain from fouling, adds weight to the link and prevents the link from deforming at a relatively low load. It does not increase the tensile strength of the chain, as is generally supposed.

Weldless Chain.—The term "weldless chain" covers a wide range of styles and broadly includes knotted chains, stamped link• chains, transmission bead chains, malleable chains, etc. Knotted chains bear a close relationship to the welded chain be cause they were developed, as a low-priced product, to replace small sizes of welded chain. They are practically all made upon automatic machines which fabricate the chain by straightening the wire, cutting, threading and tying, a single machine making the complete chain from the coil of wire to the finished product. There are about a dozen different styles of these chains in general use. Other forms of weldless wire chains contain no knot and con sist simply of twisted wires hooked together—such as jack chain and ladder chain. Stamped link chain such as sash chain and transmission chain require at least two operations in their manu facture. The first operation blanks the links and the second, either automatic or by hand, assembles them. Bead or ball chain, com monly used in electric light fixtures, consists of a series of hollow balls joined by solid bars, the latter having a ball or cross-pipe formed at its ends. This chain is also made entirely by auto matic machines. Jewellery chain in an almost endless variety is made from precious metals and used chiefly for ornament. Such chains are often made with oddly shaped links and with combina tions of differently shaped links. Those made automatically bear somewhat of a uniform construction throughout their length, while other designs formed and ornamented by hand, vary in details with almost every link.

Finishes used on chain include practically every known finish for which there is a demand. Many chains are sold in their natural finish, as they come from the forge or machine. Some are polished highly by tumbling in sawdust, sand or leather scraps. Protective coatings, such as asphaltum, zinc, tin and lacquer are frequently used. Various colours of paints, powders and japans are used on chains for ornamental purposes, such as chandelier chain. Still others are plated with copper, brass, chromium, cad mium, nickel and other metals or alloys. At present, Cradley Heath, in the Black Country of England, is the centre of heavy chain manufacture, while York, Pennsylvania, U.S.A., is the centre of small-chain manufacture. (H. M. B.) Testing.—Af ter welded chain is made it should be given a "proof test" and each link examined for exterior defects. The purpose of this test is to determine if there are any hidden defects which would render the chain unsafe for its rated working load. Any load which is higher than the rated working load yet lower than the elastic limit of the chain link is suitable for this proof test. Railroads, testing bureaus, large users of chain, etc., have specifications giving definite loads to which the various sizes and grades of chain must be tested by the manufacturer. For many years it has been customary to proof test welded chain to a load equal to one-half of the average ultimate tensile strength. Many chain manufacturers continue to follow this practice. Some chain authorities feel that such a load is injurious to the chain links especially when applied to iron chains. They recommend as a substitute a load about 25% higher than the working load. The statutory proof load required by the British board of trade ap plying to close-link chain for use on British ships is: proof load to be i tons, where d is the diameter in inches of the iron in the link. For stud-link chain the proof load is 5o% higher than for the open-link chain although the tensile strength is practically the same. Knotted types of chain are not proof tested. There are no standard dimensions for chain links. Link dimensions vary with different manufacturers. Well proportioned links can be de signed by making the outside dimensions 41 by 31 times the diameter of the material, for close-link chain and 6 by 3.6 times for stud-link chains. These dimensions can be varied.

Destruction Tests.

To determine what ultimate tensile strength may be expected from a finished chain a section several feet long should be tested to destruction. Toughness and ductility of the iron from which the links are made should be given greater consideration than merely high tensile strength when selecting a chain for use where a reliable chain is required. Chain with a high tensile strength is often brittle and will break without warning whereas a chain made from a ductile material will stretch con siderably before breaking. Toughness and ductility can best be determined by observing the structure of the break and by the relative amount of reduction in area and the elongation at the point of fracture. These features should be determined in a straight bar of the material from which the links are to be made. Total stretch of a chain before breaking is of little value in de termining the toughness and ductility of the material because the elongation of the chain is governed primarily by the shape of the links and not by the composition of the material.

Permissible Loading.

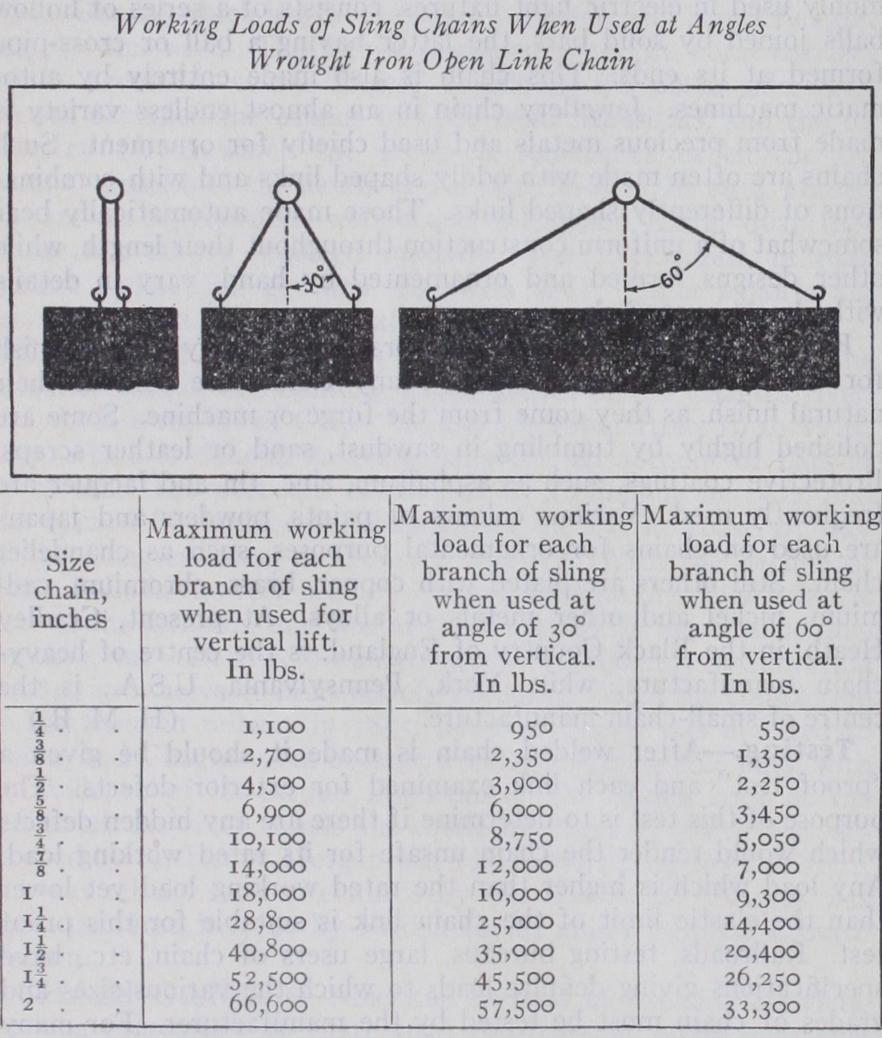

Maximum working loads for chains should be based upon the proof test and should never be higher than the rated working loads suggested by the manufacturer of the chain, individual specifications or testing bureau for the size and grade of chain being considered. Working loads are always given to be used when the chain is lifting in a vertical position. It should be noted (see table) that the working load of a chain when lifting at any angle to the vertical line is always lower than for the vertical lift. When lifting at an angle of 6o° to the direc tion of pull, as with a double sling chain, the working load is only one-half of the working load for the same chain when used for vertical lifting. (H. M. B.; W. L. GN.) two large bullets or half-bullets fastened to gether by a chain ; formerly used in naval engagements to cut rigging, etc., and sometimes in land battles as a short-range pro jectile.