Chocolate

CHOCOLATE, a preparation of the cacao bean and sugar, usually flavoured, it is used either as a food or mixed with hot water and milk as a drink. Cocoa, and chocolate for eating, are comparatively modern preparations, whereas drinking chocolate, of a sort, has been known to Europeans since the discovery of America. The original of the modern chocolate was ckiocolatl, a frothy beverage taken cold and held in high esteem in Mexico by the Aztecs. As chocolatl apparently consisted simply of the roasted and ground cacao bean flavoured with peppers and other spices, it was both bitter and pungent. The Spaniards greatly improved it by adding sugar, and guarded the secret of its prepa ration for nearly a century, when it became known in Italy, Ger many and France. In 1657 a Frenchman opened a shop in Queen's Head alley, Bishopsgate street, London, at which solid chocolate for making the beverage could be purchased at los. to 1 5s. a pound. At this price, only the wealthy could afford to drink it ; hence the appearance in London, Amsterdam and other European capitals of the fashionable chocolate houses, some of which de veloped later into famous clubs. About i 70o the English improved chocolate by the addition of milk. The reduction of the cost of the beverage was hampered in Great Britain by the imposition of high import duties on the raw cacao bean, and it was not until when Gladstone lowered the duty to a uniform rate of id. a lb., that chocolate became popular.

Cakes of chocolate are still the accepted material in France from which to prepare a cacao beverage, but elsewhere cocoa powder has for many years been more generally used. (See COCOA.) Whilst the use of chocolate for drinking has declined, the amount of chocolate eaten has greatly increased.

Method of Manufacture. The

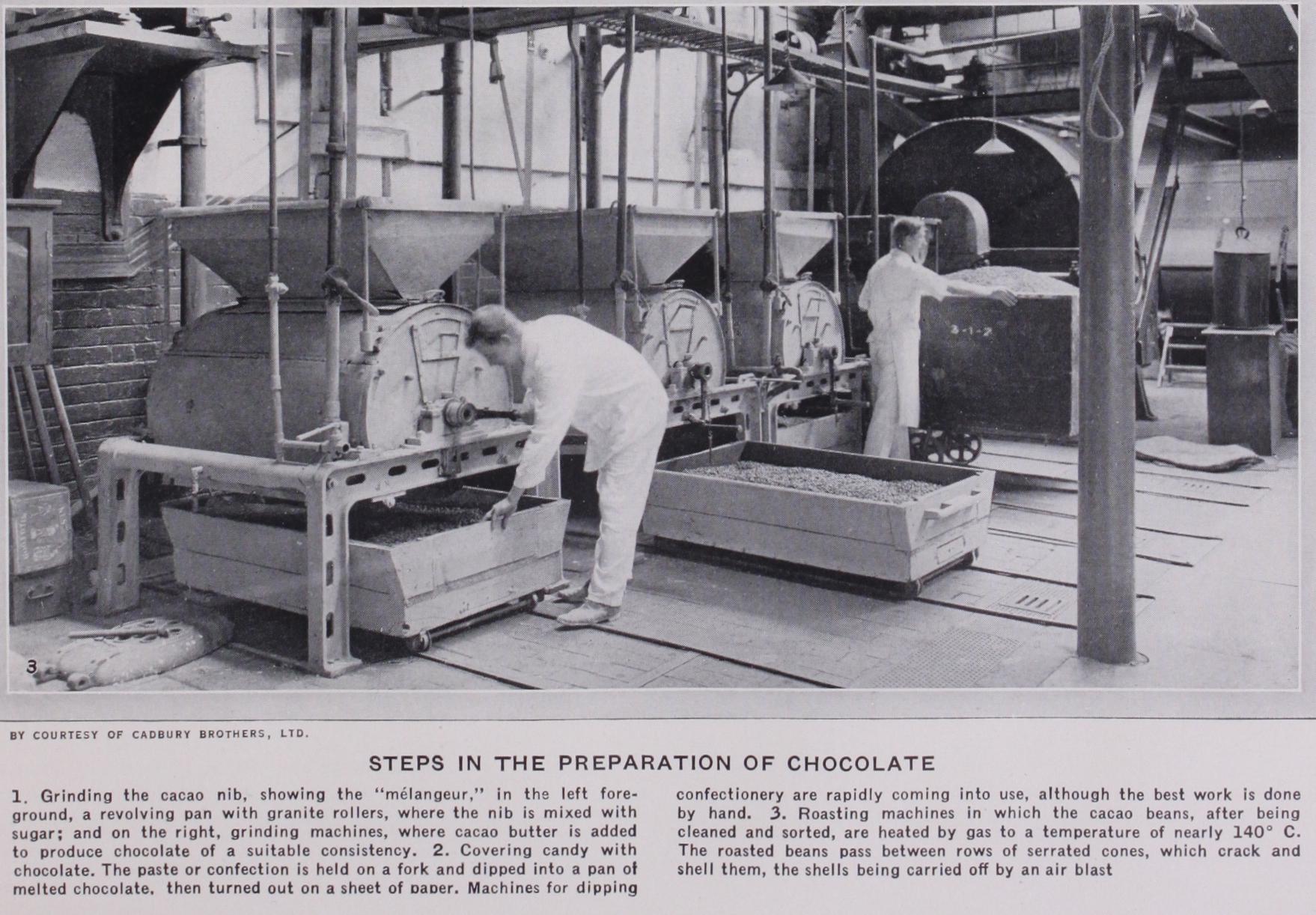

cacao beans having been cleaned, roasted and broken, the shell is removed and the pure "nib" is ground to "mass." The methods are exactly those de scribed under COCOA, save that the temperature of roasting is lower. The sugar used may be clear crystalline granulated sugar, powdered sugar, or the so-called "amorphous" sugar prepared from boiling sugar syrup.Either cacao nib or mass is mixed with the sugar in a melangeur, a revolving pan with granite rollers. The mixture is repeatedly ground in some form of disintegrator or mill. Grinding rolls made of quartz diorite, porcelain or steel, are generally used. An im portant exception is the use of vertical revolving steel disks in U.S.A. for the production of the cheaper covering chocolates. In grinding and in later stages (e.g., before moulding) it is necessary to add cacao butter to obtain a chocolate of a suitable consistency —the final chocolate containing perhaps 33% cacao nib or mass, 54% sugar and 13% of added cacao butter.

The flavours of modern chocolates are the result not merely of the blend of beans, the choice of vanilla, cinnamon, aniseed or other spice or flavouring, but also of the special processes which they undergo. Many novel machines, the most popular of which are called conches, are used, in which the chocolate is agitated, mixed, ground or heated often for several days, to give a smooth, mellow and finished confection.

The chocolate so obtained is, when warm, an aromatic plastic dough. It remains to mould it in the familiar cakes, bars, disks (croquettes) or small rectangular tablets (Neapolitans). Before moulding, it is necessary to bring the chocolate to a temperature of 9o° to 93° F by passing it over warm rolls or other conditioning device. A machine deposits a definite amount into moulds, which then pass over a shaking table. The chocolate spreads out, and any air bubbles rise and break. The moulds pass through a cooling tunnel, and as the chocolate sets, it contracts, coming from the mould clean and bright, with a rich colour, and so hard that it snaps when broken. The final process of covering with tin or alu minium foil and paper, is accomplished by automatic machines.

Chocolate in block form is recognized as a compact and valu able foodstuff. It is not only sold plain, but is combined with other foodstuffs, for example, various nuts and dried fruits. A preparation with milk for making a drinking chocolate was an English invention; much later (1876) M. D. Peter of Vevey, Switzerland, produced milk chocolate for eating, which is a mix ture of cacao nib, sugar, cacao butter and milk. In England milk chocolates containing a very high percentage of milk are pre ferred, a popular make containing 1 z pints of milk (minus its water) per pound of chocolate.

Chocolates or Chocolate-covered Confectionery.—Choco late is used for covering all manner of confections. It is prepared by the methods outlined above, but more cacao butter is added to make it flow readily. The best work is done by hand : the vanilla creme, caramel, or other confection is laid on a fork and dipped beneath the molten chocolate, and then turned on to a sheet of paper. A mechanical coverer or "enrober" invented in 1903, is much used ; in this machine the cremes move on a woven wire band through a cascade of liquid chocolate. The decoration and boxing of chocolates are light occupations which offer employment for a large number of girls.

Cacao Butter.

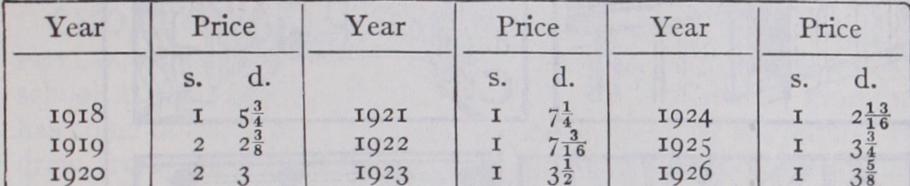

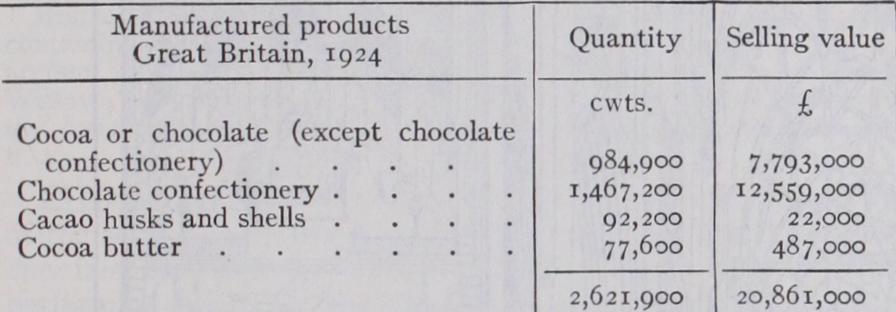

Cacao butter (cf. CocoA) is a pale golden yellow butter with a brittle fracture and a characteristic fragrance. Whilst a little is used for making high-class cosmetics and lip stick, the great bulk is used in making chocolate covering and milk chocolate. This use of cacao butter makes the cocoa and chocolate industries interdependent. In the joint industries, from 2 lb. of cacao nib and I lb. of sugar is obtained roughly 1 lb. of cocoa and 2 lb. of chocolate.Cacao butter is the most costly vegetable butter of commercial importance. The following are the average wholesale prices per lb. of prime duty-paid English cacao butter for the years 1918-26: Production of the Cocoa, Sugar and Confectionery Trades.—The following figures taken from the Board of Trade returns relate to 1924. The total number of persons employed in Great Britain in the cocoa, chocolate, sugar confectionery, jam, etc., factories and workshops was females; 26,238 males). The cost of the material used was L24,092,000 and the total value of the goods made was f41,225,000.

The general facts of the industry are to be found under CocoA and CONFECTIONERY. According to the United States Biennial Census of Manufactures of 1925 the total value of products of manufactures of chocolate and cocoa was $100,420,000. Of this amount, $37,415,000 represents the value of 145 404,000 pounds of chocolate (not including chocolate coatings) ; $4o,188,000 the value of 223,954,000 pounds of chocolate coatings; $9,17o,000 the value of 78,398,00o pounds of powdered cocoa; $10,760,000 the value of 38,044,000 pounds of cocoa butter; and $2,886,000 the value of other products, chiefly chocolate and cocoa specialties. In the 58 reporting establishments there were 7,018 wage earners, who received $7,861,000 in wages. During the calendar year ending Dec. 31, 1925 the United States imported 382,019,264 pounds of raw cocoa, valued at $38,246,157; of prepared cocoa (not including confectionery) 5,089,162 pounds, valued at $1,165, 896. (See Cocoa Production and Trade, Dept. of Com. and Labor, Washington, D.C., 1912.) Home-made Chocolates.—A simple recipe is as follows : Take 2 lb. covering chocolate and 4 oz. unsweetened chocolate, cut very small and put in aluminium pan over very slow heat. Stir till smooth. Stand the pan in cold water, and stir until the chocolate thickens. Replace over gentle heat and beat well for 20 minutes.