Clothing Manufacture

CLOTHING MANUFACTURE. The application of the sewing-machine to tailoring made the production of ready-made clothing possible in bulk. The early demand for ready-made cloth ing may be traced to the older seaport towns, where such clothing was often required at short notice by persons returning from long voyages. The foundations of the wholesale clothing industry, how ever, may be said to rest first, on the invention of the sewing machine ; and secondly, upon the introduction of cheap (shoddy) cloth made from pulled-up rags, from which material machine made clothing, produced in bulk, was originally made. The use of shoddy has practically disappeared, however, and the finest grades of cloth are quite generally used by the best manufacturers of ready-made clothing, who are also in a position to employ highly qualified designers.

Thimmonier's Sewing

Machine.—Ready-made clothing was first made in Paris by a tailor named Thimmonier, who invented the first sewing-machine in 183o, and applied it with considerable success to the production of army clothing until 1841, when his factory was destroyed during a machinery riot. Thimmonier after wards went to England with an improved machine which he patented in 1848. This, however, met with no success, and it was not until 1851, when the American invention of Isaac Merritt Singer was introduced into England, that the industrial potentiali ties of the sewing-machine were realized.The quicker output obtained by mechanical sewing necessitated an increase in the speed of pattern cutting, and 186o saw the in vention of the cloth-cutting band-knife (based on the principle of the band-saw), which solved the problem of supplying material to keep pace with the work of the sewing-machine. This machine was made in Leeds by Messrs. Greenwood and Batley at the suggestion of Mr. (afterwards Sir) John Barran, a native of London who had settled in Leeds some years previously, where he had commenced the wholesale clothing industry in 1855. The modern machine has a knife velocity of 7,000f t. per minute, and can cut 5o thicknesses of cloth at once. A more modern style of machine still is a portable knife-cutter worked by electricity. Other inventions, mostly in connection with sewing, followed in rapid succession ; and sewing by hand for joining most parts of a garment is now almost entirely superseded by machines de vised for such special purposes as felling (i.e., turning over the edges of the cloth and then sewing in order to prevent fraying), sleeving, button-hole making and button stitching. A machine for marking the outlines of the patterns to prepare them for cut ting, and machines for pressing have assisted further to reduce handwork to a minimum ; and the transition from operating the sewing-machines by hand or foot to power driving has contributed to greatly increased output and cheaper production.

Division of Labour.

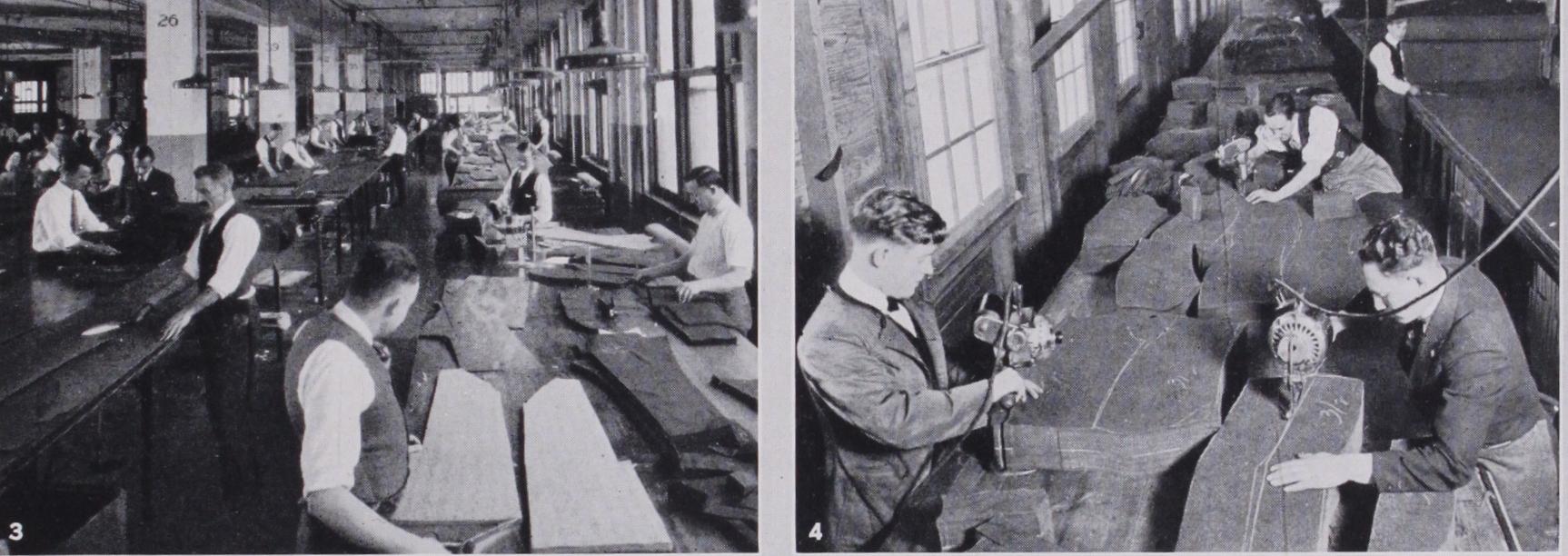

The modern factory system is highly sectionalized, and its production and output depend upon an extraordinary degree of subdivision of labour; so much so, that a coat, in making, may pass through the hands of as many as 5o persons. Subdivision of labour reduces the cost of production by causing the simpler processes to be effected by the unskilled labour of young persons, and utilizing skilled labour only for the more complicated work.The system originates with the designing and production of the patterns in the various standard sizes by the head pattern or stock cutter, who is responsible for keeping in touch with move ments in fashion and "style." The separate paper pieces com prising a pattern for a garment or suit are then formed into what is termed a "lay" by fitting them as closely together as possible (interlocking them after the manner of a jig-saw puzzle), so in cutting out the cloth there will be a minimum of waste; the operation being termed "lay-getting." The outlines of the lay are ' chalked on a large piece of tough paper or linen corresponding in width to the cloth, and then these are perforated by a machine called a "process-marker," thus forming the pattern or lay from which the garments are cut in bulk. To prepare the cloth for mechanical cutting, it is automatically folded in the number of lengths required by the "laying-up" machine; the lay is placed on the top fold, and specially prepared powdered chalk is rubbed through the perforations to indicate the lines to be followed by the knife. After cutting, the pieces for each individual garment are sorted out and numbered, tied into bundles with their neces sary trimmings, which have been prepared in a similar manner to that just described, and passed forward to the factory for making up. Here, the various parts are sewn and gradually assembled into the complete garment—this being a combination of hand and machine work by trimmers, finishers, machinists (who work the specialized sewing-machines) and pressers.

The industry has been built up in Great Britain very largely by the exploitation of alien Jewish labour, and in fact, the origin of the subdivisional system of work was the outcome of the necessity for finding employment for the great influx of Russian Jews to London. These unfortunate people usually carried on their occupation at home, and by reason of their poverty and consequent low standard of living worked for very low rates of payment. This quickly resulted in the "sweated labour" conditions exposed by Charles Kingsley and other social reformers. In 1909, when the first Trade Board act was passed, ready-made and wholesale bespoke tailoring was classed among the four in dustries having "rates of wages exceptionally low as compared with those in other employments." The Tailoring Trade Board was established under this act in the following year with powers to determine the minimum rates of wages in all branches of the tailoring trades, and in 1920 two separate boards were constituted —one to deal with the ready-made and wholesale section, and the other to control the retail bespoke section of the industry.

Location of Industry.

Though London was the original home of the British ready-made clothing trade, Leeds is now the chief seat of the industry, and wholesale clothing with its 400 firms providing employment for over 30,00o persons forms the premier trade in the city. There is a difference, too, in the conduct of the 'industry in the two centres; in Leeds it is almost entirely confined to work in the factory ; in London, "outworking" persists to a large extent. Leeds was the first provincial town (in to engage in the industry, and no doubt owes its present leading position largely to its advantageous geographical situation in the centre of the West Riding of Yorkshire woollen and worsted cloth manufacturing area, which supplies it with all classes of fabrics from the lowest to the highest in quality. The manufac ture of clothing is also carried on in the Huddersficld and Hebden Bridge districts, Liverpool and Manchester, Bristol, Colchester, and Leicester; and in Scotland, Glasgow is now an important centre. There are nearly 6,000 firms in Great Britain with a personnel of over 200,000 persons.It may be noted here that though ready-made clothing was identified formerly with inferior materials only, this is no longer the case, and there is now a large and increasing demand for "ready-for-service" (to use the latest description) garments of high class workmanship, made of the finest quality materials.

With regard to markets, it is generally considered that about two-thirds of the. yearly British output is absorbed at home, and the remainder goes principally to the British colonies, though the United States of America is a considerable customer for the best class of British goods in spite of her own high standing in the industry.

There are two associations of British employers: (1) the Whole sale Clothing Manufacturers' Federation (founded in 1910) which has its headquarters in London, and local branches in all clothing centres; and (2) the Northern Clothing Manufacturers' Associa tion which has its chief office at Leeds. Employes are repre sented by the Tailors' and Garment Workers' Union of Leeds and London and other organizations.

Technical education is provided for at the Leeds Technical college (both day and evening courses), and also by the London County Council. (A. Y.) United States.—Clothing manufacture in the United States has passed largely out of the hands of the merchant tailor and was in 1928 conducted in modern plants equipped with labour saving machinery. It has been estimated that between 8o and 90% of the men's clothing made in the United States is of the "ready-to-wear" type. Most of this clothing is produced in the centres of population, although in recent years there has been some migration of factories to smaller cities in order to reduce production costs by cheaper labour and lower factory rental costs. New York city is the most important clothing market, making about of the total clothing produced in the country. Many out-of-town factories maintain sales offices in the metrop olis. Other important clothing centres are Chicago, which pro duces about 15% of the total volume for the country, Cincinnati, St. Louis, Philadelphia, Boston, Buffalo and Rochester.

In New York city the greater part of the clothing is produced under the "contract" system. The manufacturer cuts up the cloth into the various patterns he desires and this cloth is sent to a contractor for fabrication into garments. This system partly accounts for the large number of clothing firms in New York city, for it enables a person to enter the business with com paratively small capital. In the other clothing centres the "con tract" system of production is carried on only to a small extent, most of the clothing manufacturers maintaining their own fac tories.

The success of mass production in the clothing industry in the United States that has developed since the loth century began, rests upon (1) scientific pattern construction ; (2) highly efficient labour saving machinery; (3) effective factory arrangement; (4) high division of labour; (5) economies effected in the purchase and fabrication of materials on a large scale, and (5) standardiza tion of styles. The industry did not make any great progress until scientific investigations of average proportions of the hu man body yielded sufficient information on which to base the present art of clothing designing. Experience has disclosed that normal proportions and variations therefrom are fairly constant in any group of 10o men, and consequently, clothing manufac turers make their garments in assortments complying with such experience. For a retail store carrying 500 suits, some manu facturers recommend the following assortment : 45% regular; 6% long; 13% short; 2% extra short; 8% stout; 3% short stout; 2% long stout; 4% portly; 2% long portly; 3% short portly; 3% forward; 3% young stout; 3% stalwart; 2% cor pulent. All stores do not carry, nor do all factories make assort ments as complete as above. However, the more complete the range of sizes, the less alterations, or busheling, must be made. These busheling operations are standardized, and because of the high development of the art of making ready-to-wear clothing in the United States, changes are usually slight.

In making a new model sack-coat or overcoat, the designer visualizes the style he wishes to create and drafts a pattern, usually size 36. This pattern is used to derive a complete set of patterns for all required sizes, including regulars, shorts, longs, stouts, etc. This work of translating the basic pattern into other sizes is called "pattern grading." Considerable skill and experience is naturally required for successful clothing designing. In many American factories the designer not only designs the models, but he also supervises the general production of the garments in the factory.

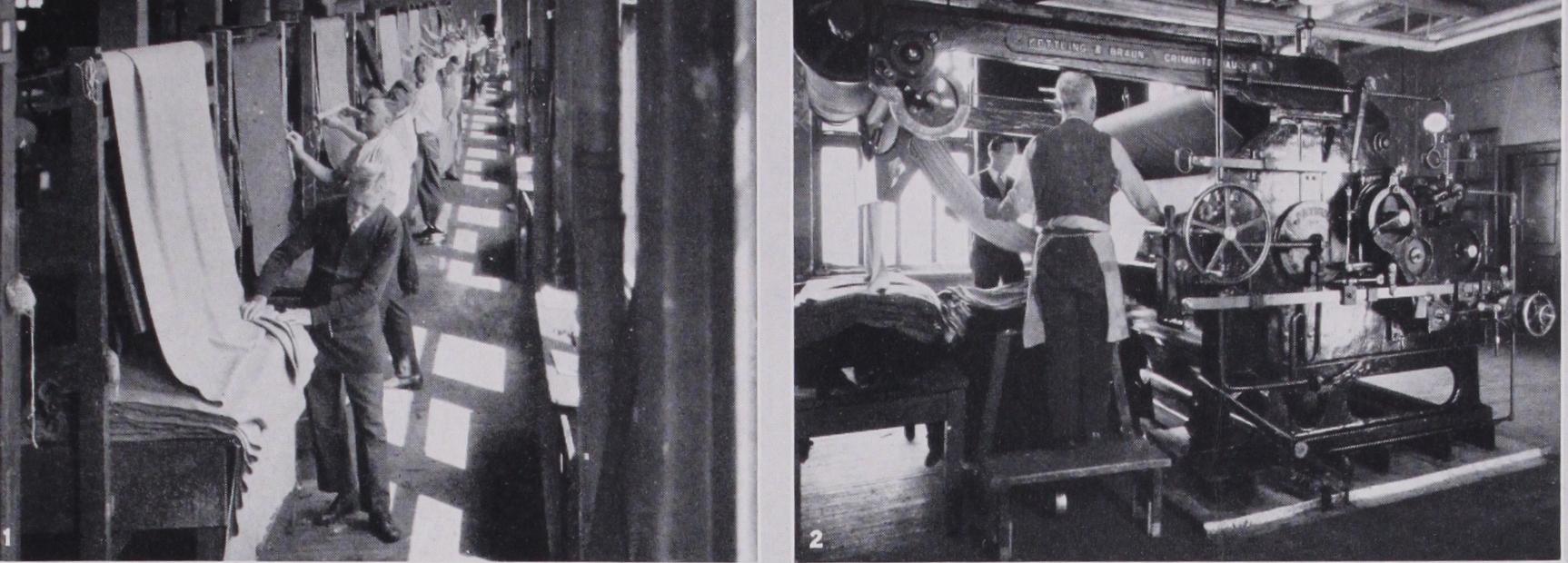

Two methods of cloth shrinking, or sponging, are in use : the cold water, or London process and the decating method. Cloth shrunk by the London process is passed through a vat of water and hung in folds on rods to dry. This method is used chiefly for worsteds and serges. Most of the fabrics used for clothing manufacture in the United States are treated by the decating method. The cloth is wound on a metal cylinder perforated by many small holes through which steam emerges and passes through the cloth. After remaining on the cylinder for about three minutes the cloth is wound on a roller and allowed to dry. Some houses treat all their fabrics by this method, which, while not as good as the London method, is rapid and less expensive. Less shrinkage results from decating than from the use of the London method. The extent of shrinkage depends upon the type of fabric and method of shrinkage, ranging from 3 to as high as 8 or 9%.

After the cloth has been shrunk and dried, it is laid out on cutting tables in "lays" from a few thicknesses of cloth to as high as 50 or 6o in the case of work clothing. The cardboard patterns are laid on the cloth in such a manner as to conserve every possible inch of cloth. After the outlines of the patterns are chalked on the top layer of the lay the outlines are cut by electric cutting machines. These machines are of two types; the one having a revolving disk cutter and the other having a vertical blade moving up and down. The great amount of labour saved from this method of cutting is difficult to estimate. In even a small establishment thousands of garments may be cut from a single pattern.

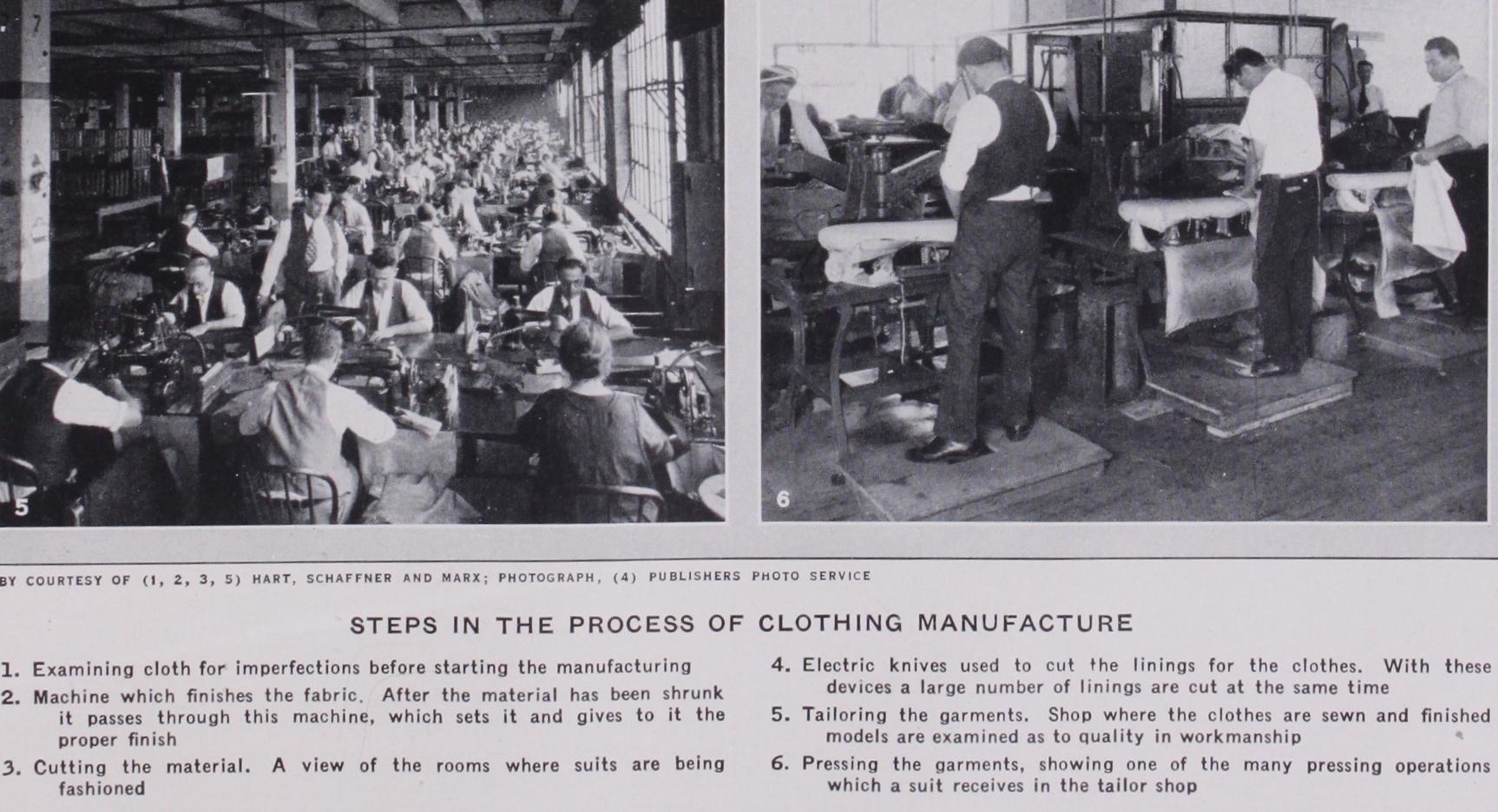

Most cutting rooms are located on the top floor of the factory so that the cloth after cutting can pass through the assembly departments to the stock room by means of gravity or other con veyors. The factory is usually laid out so that each operation follows in sequence to avoid unnecessary handling of the gar ments. The pieces of cloth are tied together and they are then distributed to the coat, the vest and the trousers departments. Usually one-half of a garment is made in one section of the de partment and the two completed halves are finally joined together. Division of labour is carried out to a very high degree. Each operator performs but one task on a garment, thereby gaining un usual proficiency. In the making of some pockets, for example, there are 13 different operations, each one of which is performed by a single individual. One hundred persons may work on a sack coat. Not only does an operator do more work under this system, but because of the skill he develops, he does better work. This high division of labour also permits the use of workers possessing ordinary intelligence. Practically all clothing factories in the United States operate on a piece work basis; i.e., a unit price is fixed for each operation on a garment.

Much labour saving machinery for the clothing industry has been perfected in the United States, by means of which the various operations are speeded up and the unit costs reduced. Dozens of improved types of sewing machines have been intro duced which are very instrumental in reducing costs. The late models of button-hole machines cut the cloth, sew and tack the buttonhole in a fraction of a minute. Buttons are sewed on by machine and seams in trousers are pressed by an ingenious de vice in a quarter of the time required by hand. One of the out standing developments in labour saving machinery is the steam pressing machine. In establishments making higher grades of clothing, the garment is pressed of ter each important operation. The steam pressing machine now in use is made in a variety of models having bucks shaped to fit various parts of the garment. The garment to be pressed is placed on the buck, which is canvas covered, and a counter-balanced canvas-covered block, hinged to the frame supporting the buck, is pressed down on the gar ment. Steam is forced through the garment. This steam is usually drawn away by means of a vacuum system. The steam pressing machine has very materially lowered clothing pressing costs. All operations, however, are not performed by machinery. Some hand-work is required on all ready-to-wear clothing, and as many as 20 or more operations are done by hand on higher priced ready-to-wear garments.

Another factor that has had an important influence in stab ilizing and reducing waste in the clothing industry in the United States is the semi-annual style forecast prepared by the Inter national Association of Clothing Designers. Conventions are held in January and July each year by the association and pro posed models for the following season are exhibited, from which the style forecasts are prepared. These forecasts serve as a guide for designers and tend to standardize styles for each season. This permits manufacturers to concentrate production on salable models, and at the same time does not eliminate the element of style.

The manufacture of men's clothing is one of the important industries in the United States. According to the last report of the U.S. bureau of census (192 5) there were 4,00o clothing estab lishments reporting to the bureau. These had workers and the value of their products for 1925 was $1,o87,238,000.

(C. LE.)