Clutch

CLUTCH, a device by means of which connected shafts m other mechanisms, such as engaging pulleys, gears and other rotat ing parts, may be disconnected at will. A clutch is frequently required to operate many times in the course of a minute and, as in the spindle of the automatic screw machine, which often runs at 5,00o r.p.m., it maybe required to reverse its action several times within a few seconds. Clutches may be divided into two general classes, namely : Positive clutches and friction clutches.

Positive Clutches.

The sim plest form of positive clutch is the jaw or claw type shown in fig. I. One part of the clutch is keyed - or pinned rigidly to the shaft while the other part is slot ted, thus permitting it to be en gaged with, or disengaged from, the first part by sliding it along the shaft. The interlocking jaws upon the abutting faces of the clutch may have various forms.In machine tools the jaw clutch is applied extensively and is used for instantaneous disconnection of a drive to a feed screw. An automatic trip device jerks the clutch teeth out of mesh. A spiral claw clutch is utilized so that a drive cannot be reversed, this act forcing the teeth apart. Both types are shown in fig. 1.

The number of jaws on clutches depends upon the promptness with which a clutch must act. In punching and shearing machin ery, the number varies from two to four, while in other classes of machinery the number of jaws may run as high as 24.

The freewheel clutch, commonly applied to bicycles, but hav ing other mechanical applications, is another form of positive clutch. This engages the rear sprocket with the rear wheel when the pedals are rotated forwards and permits the rear wheel to revolve free from the rear sprocket when the pedals are stopped.

Friction Clutches.

The object of a friction clutch is to con nect a rotating member to one that is stationary, to bring it up to speed, and to transmit the required power with a minimum amount of slippage. In connec tion with machine tools, a friction clutch introduces what might be termed a safety device in that it will slip when the pressure on the cutting tool becomes ex cessive, thus preventing the breaking of gears or other parts. According to the direction in which the pressure between the contact surface is applied, fric tion clutches may be further divided into axial clutches and rim clutches.Axial clutches manufactured by the various builders of trans mission machinery, machine tools and motor cars, are usually of one of the following three types : Cone, disc and combined coni cal disc. The cone clutch is the simplest form of friction clutch that can be devised, and if properly designed will give entire sat isfaction in many mechanisms such as lathes, machine tools, hoisting apparatus, lorries, heavy automobiles. Two types of cone clutches, the single-cone and the double-cone, are usually met with. The single-cone clutch consists of a "male" cone of cast iron or specially treated steel keyed rigidly to a driving shaft with a second or "female" cone faced with cork, leather, asbestos, or other material, which is fitted to the driven shaft by means of a feather key. This key permits the driven cone to be engaged with the driving cone, thus transmitting the power from one shaft to the other. The hub of the driven cone is fitted with a groove into which a shifter collar is operated by the engaging lever or toggle as shown in fig. 2. When applied to vehicles the operating lever is usually replaced by a strong spring which performs the same function. The double-cone clutch is based on similar principles. The disc-clutch—known also as the plate clutch (fig. 3)—is a series of discs arranged in such a manner that each driven disc is located between two driving discs. The two types in common use are the single disc in which a single disc serves as the driven member and the multiple-disc in which two or more discs act as the driven member. The single-disc clutch construc tion includes a fabric-faced disc which is gripped on each side between a fly-wheel or other member and a pressure disc forced up by springs, toggle levers or other de vices. Multiple-disc clutches are capable of transmitting large powers at high speeds and have wide usage in motor cars, lorries (trucks), cranes, hoists and heavy gearing.

A special form of hydraulically operated disc clutch is used in some American vessels, such as torpedo boat destroyers, to disconnect the cruising engines from the turbine shafts without stopping the propelling machinery.

In addition to the asbestos-fabric faced steel disc used for the friction surfaces, the following are sometimes used : Steel against steel ; steel against steel with cork inserts ; steel against bronze. A combination of steel and bronze working in oil or dry steel and fabric may be used.

A combined conical-disc clutch is one in which the contact sur faces of the disc or discs are conical. In the Hele-Shaw conical disc clutch, shown in fig. 4, the driving and driven discs have a V-shaped annular groove, the sides of which form the surfaces in contact. Phosphor-bronze driving discs are provided with notches on the outer periphery which engage with suitable projections on the pressed steel casing. The mild steel driven discs have notches on the inner bore which engage with the corresponding projections on a steel spider which is splined to the shaft. The V groove in the discs permits a free circulation of oil, and at the same time en sures fairly rapid dissipation of the heat generated when the clutch is allowed to slip.

One of the recent developments with the disc type is the mag netic clutch. No toggles, lever or mechanical movements are fitted, but the friction surfaces are brought together by magnetic force when the current is switched on. As may be seen in fig. 5 the driven disc is held a little way off by a spring plate. As the coils in the driving disc are energized the resulting magnetic pull draws the driven disc against the friction lining.

The magnetic pull does not attain its full value immediately and consequently the start is made without grabbing.

In the rim-clutches pressure is obtained on the periphery of a rim and the various designs are known as block, split-ring, band, and roller, depending upon the man ner in which the pressure is applied to the exterior or interior of the rim. Block clutches are used chiefly on line shafts and countershafts, although there are several designs that have given good service on machine tools. Split-ring clutches are used for all classes of service but their greatest field of application appears to be in connection with machine tools, or in places where the diam eter of the clutch as well as the space taken up by the clutch is limited. Band clutches are usually installed when it is necessary to transmit heavy loads accompanied by shocks, as for example, in the drives of rolling mills and heavy mine hoist. The roller clutch is used principally for punching presses.

A block clutch used for shaft work consists of a shell running loose on the shaft, into which are fitted two brass or bronze shoes. The shoes are fastened loosely to a sleeve, which in turn is slotted to the shaft. The shoes are pressed against the inner surface of the shell by means of an eccentric screw or wedge.

The split-ring clutch consists of an outer shell running loose on a shaft or sleeve ; into this shell is fitted a split-ring. The latter may be expanded by the action of a pair of levers as shown in the Heywood and Bridge clutch in fig. 6, or by means of a wedge. A sliding sleeve forms a convenient means of engaging a suitable lever. A sliding sleeve, operated by a suitable lever, forms a convenient means of engaging the split ring with the outer shell.

In general, a band clutch consists of a flexible steel band, either plain or faced with wood or asbestos fabric, one end of which is fixed and the other is free to move in a circumferential direction. Due to the pull exerted by the operating mechanism on the free end of the band, the latter is made to grip the driving or driven member.

The roller clutch has a cam keyed to the crankshaft on the cir cumference of which a number of recesses, forming inclined planes, have been cut. Rollers, rolling up these inclined planes due to the action of a shell, wedge themselves between the cam and the clutch ring, thus causing the crankshaft to rotate with a flywheel. The rollers are held in place and controlled by a shell which is connected with the crankshaft by means of a spring, which is in turn operated by a treadle.

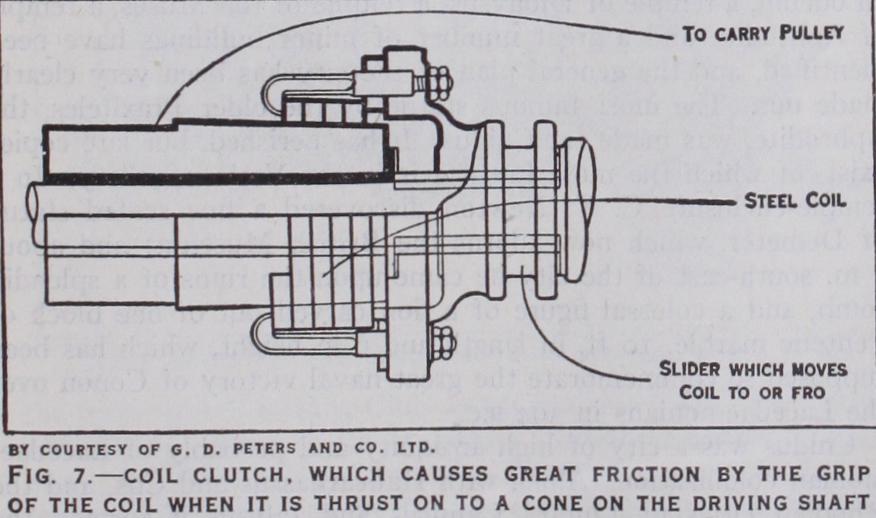

In rolling mills a special friction clutch, known as a "coil clutch," having a flexible steel coil connected with the driven shaft and a cone on the driving shaft has been brought into use. This type of clutch has very sensitive control. On a test made in a rolling mill, a load of II tons was lowered by means of a crane on to an egg without crushing it and held there for three minutes A special application of the block clutch is the "centrifugal clutch" which, by utilizing the principle of centrifugal force, throws out slipper-blocks against the interior wall of the clutch to enable an electric motor to obtain a proper start before pick ing up the load. The weight of the shoes is so regulated that when the motor is running at full speed the power transmitted by the shoes equals the power of the motor and all slip ceases.

In motor car service, it is very desirable that the car be started without jerks. In order to secure smooth clutch engagement, the designers of clutches were compelled to originate devices that insured evenness of contact between the friction surfaces. In gen eral the function of these devices is to raise slightly the cone facing at intervals around the periphery so that upon engagement only a small portion of the friction surface comes into contact with the flywheel rim. As soon as the full spring pressure is ex erted, the facing is depressed and the entire surface of the cone becomes active. In addition to securing smooth and easy clutch engagement some means must be provided to prevent the spin ning of the clutch when it is disengaged. By keeping the size and weight down to a minimum spinning may be reduced slightly. To overcome the spinning action completely small brakes that are brought into action when the pedal is depressed must be pro vided. (F. H.)