Cotton

COTTON The finishing of cotton fabrics was originally the final operation performed on the fabrics to make them ready for sale. In its modern significance, finishing comprises a large and diverse range of processes intended to produce in the fabric a desired appear ance or feel ; and the machines required for this purpose are correspondingly numerous and varied ; finishing operations require plant for, to name some of the important processes, shearing, stretching, drying, damping, pressing, embossing, impregnating, covering and raising cotton cloths.

Classification of finishes in relation to the many different kinds of cotton fabrics is difficult, because many of the processes are applicable to a wide range of cloths. They may be considered under the following headings :-- Grey goods, i.e., cloth direct from the loom; white goods, i.e., cloth which has undergone a bleach ing process; plain dyed goods—colours and black; printed goods; raised goods.

The greater number of processes of finishing cotton goods are empirical in character; the underlying physical and chemical changes are not fully understood. A finish produced in one works may be impossible to reproduce in another works, although the same kind of plant and mixings are being used. . Even in the same works, two apparently identical machines will give appreciably different results. This is not to say that finishing is a matter of chance; there are very wide differences between the various classes of finish which differences are definable in terms of plant and mixing.

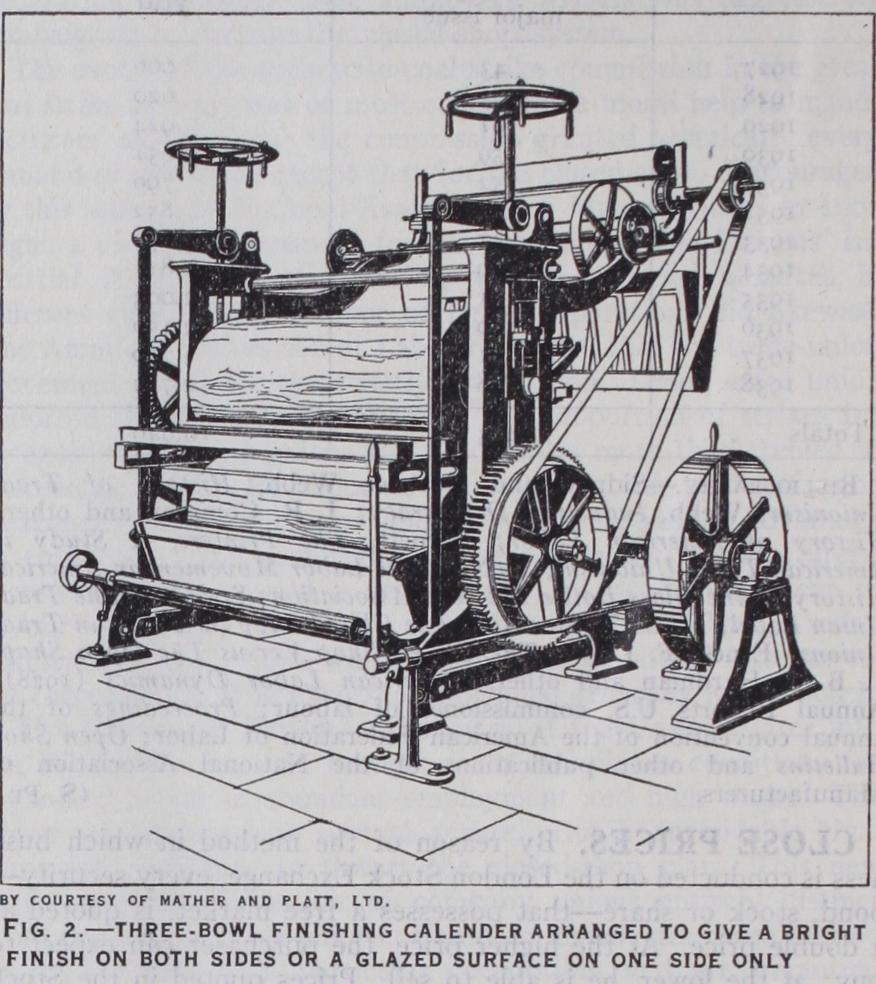

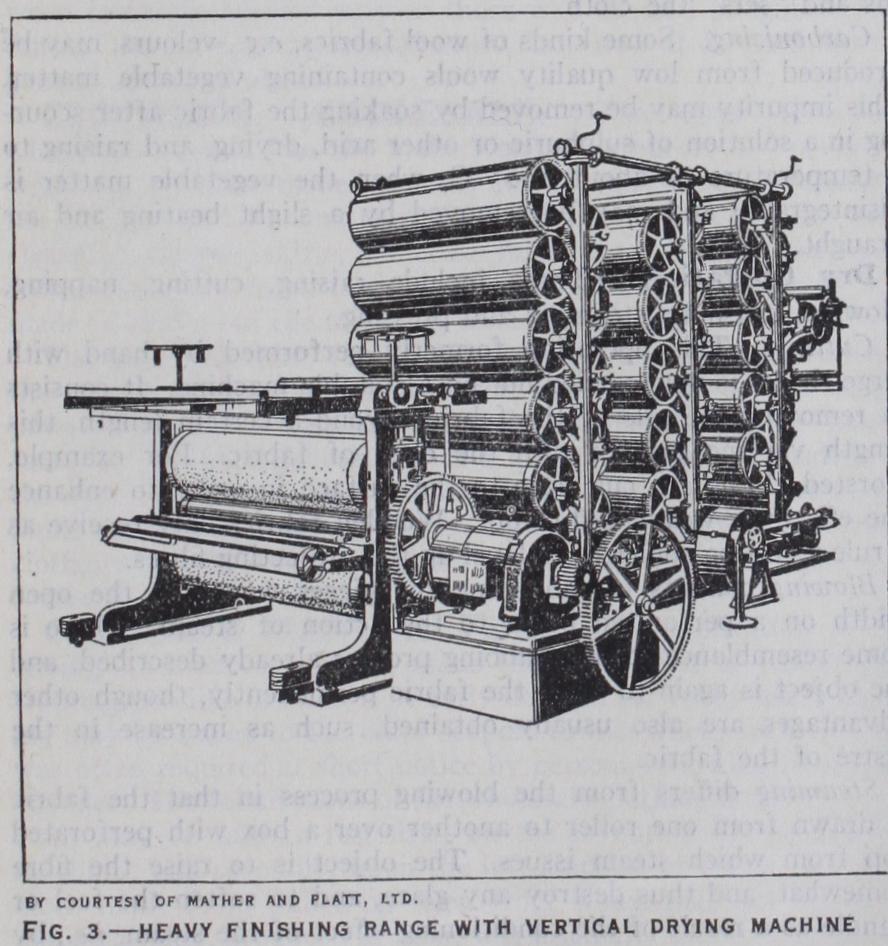

The following gives some idea of the finishing machines used for the different qualities set out above:— Grey Goods.—These may be finished pure, i.e., without any additional size or stiffening. After passing through a shearing machine or a combined moting and shearing machine, the cloth may be conditioned in a damping machine of the brush type or the spray type (fig. 1) and afterwards calendered in a suitable calender, such as the three-bowl swissing calender (fig. 2) or a five or seven bowl calender arranged to give a bright finish on both sides of the cloth, or a friction calender giving a glazed surface on one side only. Grey goods which are stiffened before being calendered are passed through a range comprising a mangle and cylinder drying machine (fig. 3) . The mangle may have two or three bowls, and the drying set may be horizontal or vertical.

Coloured woven goods, i.e., woven from grey bleached and dyed yarns, may be treated in a manner similar to the grey, making use of the same kind of machinery. Both grey and coloured woven goods may be run through the clip-stretching machine with the object of recovering width, or straightening weft, or improving the feel by breaking down the hardness pro duced in an earlier process, or lifting the figure of the original weave.

White Goods.

Here there are a very wide range of finishes requiring very extensive plant ; for example (a) Pure finish (without stiffening) ; these may, or may not be calendered or beetled.(b) Finishes requiring impregnation of the cloth with the stiffen ing mixture.

(c) "Back-filling," that is, the stiffening is applied to the back of the cloth only.

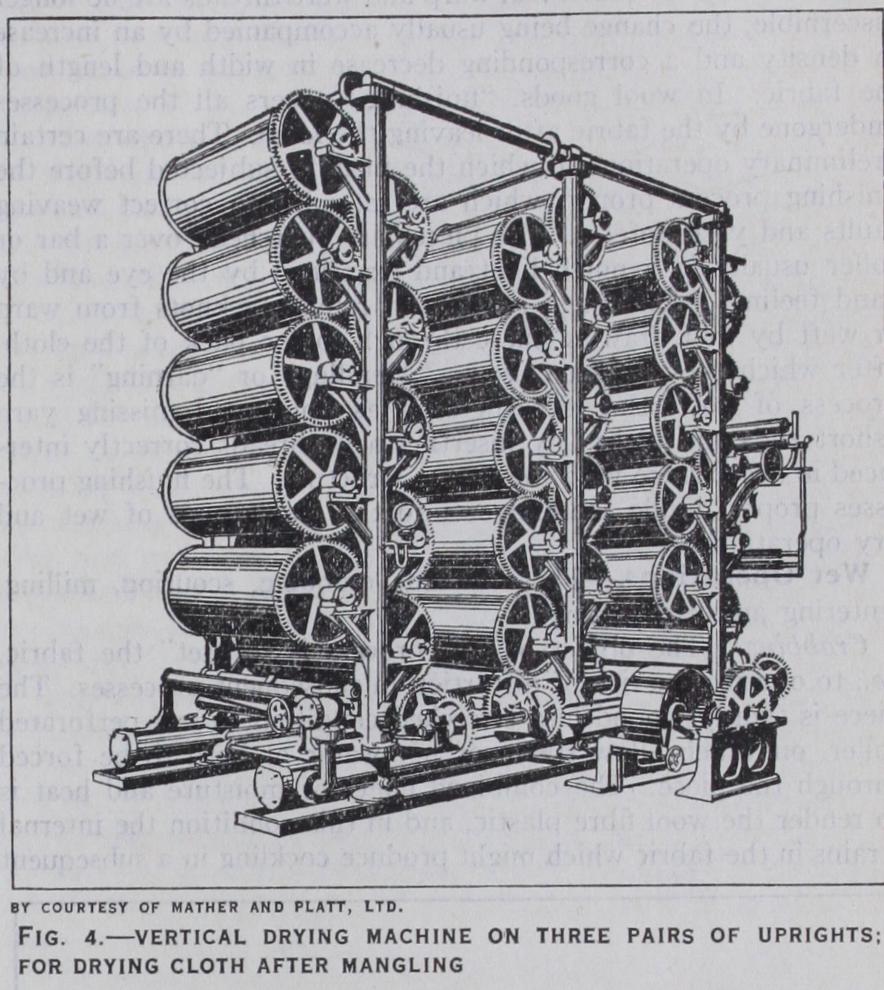

White goods are generally passed through a water-mangle with the object of improving the appearance of the cloth, closing up the threads after the bleaching process, and preparing it for the filling mixture. After mangling, the cloth is dried on an ordinary cylinder machine (fig. 4) or for twills or figured goods, additional rollers or winces are added so that the face side does not come in contact with the cylinders. White goods are usually starched in conjunction with the drying machines, as for grey, coloured woven, dyed and printed goods. Various types of starch mangles are used for this purpose ; the two-bowl mangle shown in fig. 5; the two-bowl friction calender (fig. 5) by which the filling can be forced into the cloth; the back-filling mangle.

After starching or filling, the cloth is dried over a cylinder drying machine, back-filled goods being dried over machines with the modification referred to which permits of only one side of the cloth coming in contact with the metal. Or instead of cylinder drying, the cloth may be dried on a hot-air stentering range. The starch mangle shewn in this illustration is not usual in this combination in white-finishing. By this method, any lost width may be recovered, the feel of the cloth is better, and an elastic finish may be produced by the jigging motion of the stenter, and any weft-distortion may be corrected.

The further processes may involve the use of the damping machine (fig. i) and various calenders similar to those given for grey and coloured finishing and possibly the beetling machine.

Plain Dyed Goods.—These also require a great variety of finishes, but the range of machines used is not so great as in the case of white goods, for instance, back-filling and friction starch ing is rarely employed with dyed goods. Three and four bowl water mangles are employed and a drying from these machines is generally effected on drying cylinders. The stiffening of dyed goods is carried out on a two-bowl mangle and cylinder drying machine, or preferably on a hot-air stentering range, for example, mangle cylinders and goft. stenter with hot-air drying. Damp ing machines, stretching machines, breaking machines, calenders from three to seven bowls with and without friction may be required, for certain finishes ; for producing window blinds beetles are required; Schreiner calenders for silky finishes and embossing calenders for book cloths, etc.

Printed Goods.

These are finished on similar machines to those used for dyed goods. For ordinary stiffening or starching a range comprising a two-bowl starch mangle, followed by a cylinder drying machine is employed, or a hot-air stentering range consisting of a two-bowl mangle, six-cylinder drying machine and gof t. stenter with hot-air drying. For muslins, voiles and goods requiring an elastic or batiste finish, the latter method is in dispensable. Another method of stiffening known as back starch ing, differs from the ordinary method, in that the starch paste is applied to the back or unprinted side of the fabric by means of a brass roller partly immersed in the starch box. The drying of back starched cloth is performed by passing the cloth over the drying cylinders of large diameter, say, from 5 to 7 feet, arranged in such a manner that the starched side does not come in con tact with the heated cylinders. An ordinary drying machine can be employed, but in this case, precautions have to be taken by cooling the first cylinders to prevent the starched side adhering to the cylinders. Fig. 5 shows a universal starch mangle for ordinary starching, slop starching and back starching. A back starcher or universal starcher can be used in conjunction with a hot-air stenter instead of the usual cylinder drying machine. The additional machines which may be required for finishing printed goods are similar to those already mentioned, and include clip stretchers, swissing and friction calenders, Schreiner calenders, beetles, as for dyed goods.