Gas Manufacture Coke

GAS MANUFACTURE; COKE; and Low TEMPERATURE CARBONI ZATION.) Looked at from the point of view of coal conservation there can be no doubt that a large field of fruitful possibilities exists. The wasteful and harmful process of coking coal in beehive ovens, and of burning coal for power purposes and in the domestic hearth, processes whereby the gas and other by-products are dissipated into the atmosphere, results annually in an enormous loss of po tential wealth, as well as injury to health and destruction of build ings and vegetation.

Once the leader in the manufacture of coke, there has been a failure in Great Britain to keep abreast of development in some other parts of the world in regard to constructional materials, types of ovens, size of battery, and cost of production. Where the coke produced is to be used at blast furnaces with steel works adjacent thereto, the coke oven plant will be most economically situated in close proximity to the latter, as there is then provided a source of demand for the waste gas in the steel works. If, how ever, a market exists for all the gas in the neighbourhood of the colliery for lighting purposes, then the case is reversed, and cost of transport of the coal to the steel works is saved.

In the United States of America the policy is to have the coke ovens adjoining the iron and steel works, and to have them in very large units. There are great advantages in having centralized cok ing establishments instead of many small and scattered units. A recent writer (R. Ray, B.Sc., F.C.S., The British Coking Industry and Some of its Products, Institute of Fuel, Nov. 1927), taking a battery producing 270 tons a day and comparing it with one pro ducing 1,300 tons, gives the costs per ton of the coke produced as 11s. II.53d. and 6s. 1.27d., respectively.

The manner in which coal can be conserved in the processes of carbonization lies in the prevention of waste by recovering to the greatest extent possible the potential wealth in the coal. On the other hand, were the partially coked coal resulting from the low-temperature treatment of coal to be used for domestic heat ing instead of raw coal, the probability is that the consumption of coal for household purposes would be increased by one-third, on the basis that 2ocwt. of raw coal will make I3cwt. of low temperature coke.

Waste of Coal.

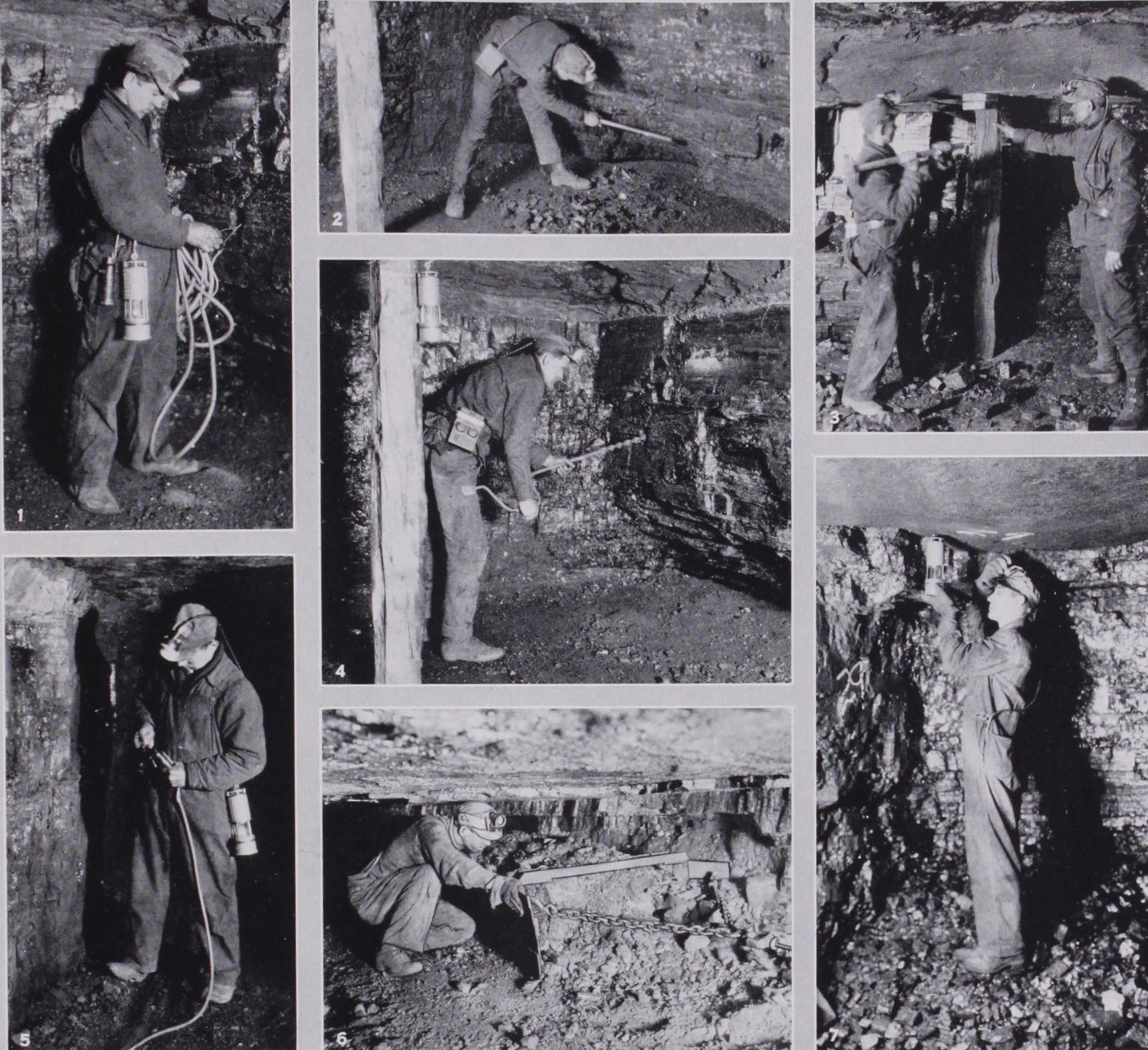

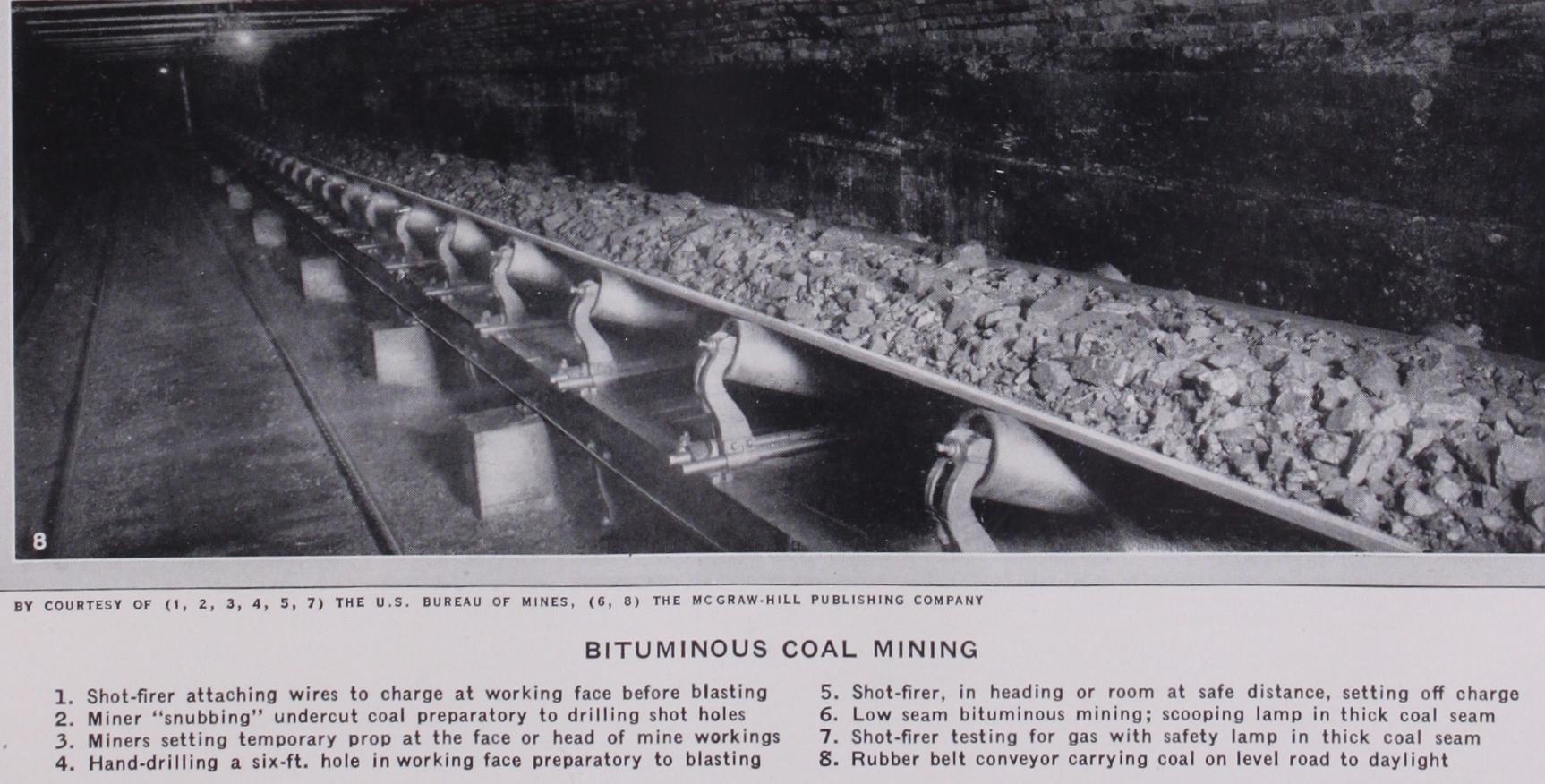

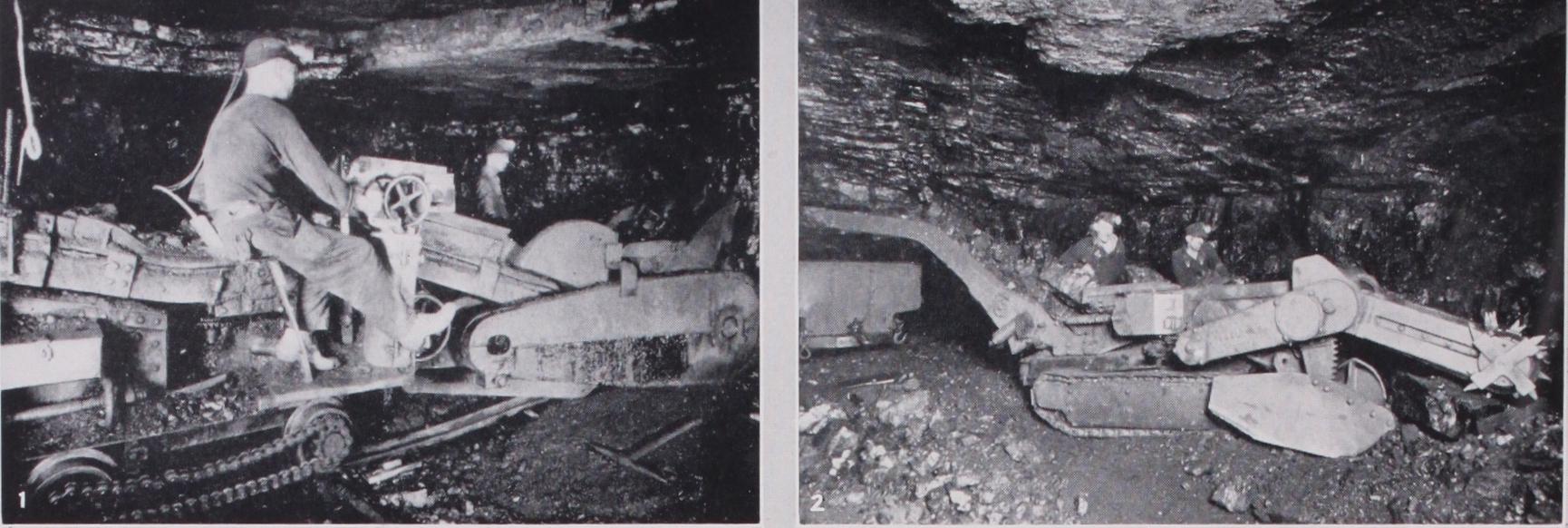

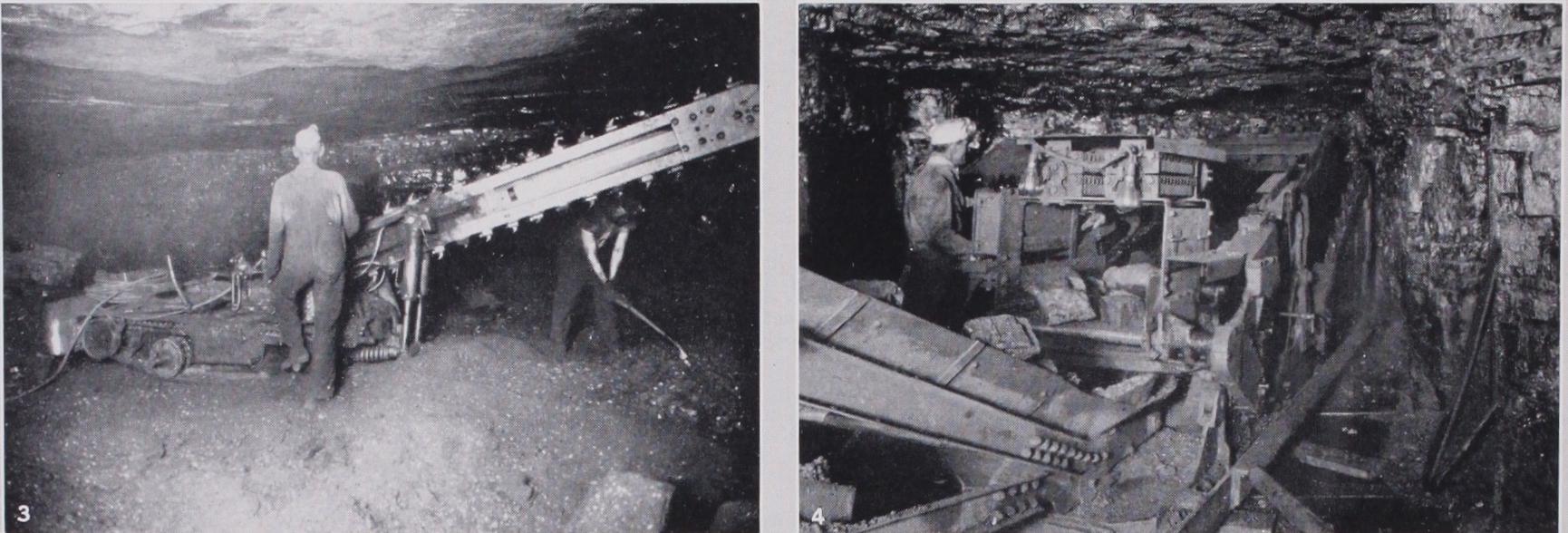

The other direction in which coal can be con served is in the process of being mined, though the loss of coal in mining is not so great as is commonly supposed and not nearly as much as it was a century ago.It used to be customary at one time—especially in some coal fields, South Wales for instance—to cast back the small coal into the goaf or waste, but very little is left underground at the present time (1928). Under I % of the total coal gotten is left under ground. The total approximate quantity of small coal cast back in the coalfields of Great Britain in the year 1917, as far as could be ascertained by the coal conservation committee, was 2,325,000 tons, of which 1,502,000 tons were attributable to South Wales. More extensive washing arrangements at collieries and in briquet ting would conduce to the absorption of this loss in normal times, but at another time the difficulty may lie in marketing what coal is produced owing to the world depression in industry generally.

One source of loss—perhaps the greatest—is that in regard to the working of very thick seams lying at considerable depths from the surface. Under existing methods of working the so-called ten yard or thick coal of South Staffordshire (fully I o,000ac. of which lie at a depth of 400yd. and more from the surface, with an average thickness of 24ft., and approximately contain a quantity of available coal equal to at least 288,000,000 tons), the loss in working the seam at this depth has been estimated at 40% or I 15,200,000 tons. But probably by a system of packing the wastes with spoil derived from the surface carried under hydraulic pres sure, or even under compressed air pressure (the latter a process now being tried in Germany), this loss will become negligible.

Other sources of loss are those due to the spontaneous combus tion of coal underground; from coal left in barriers; through coal left for support ; through the drowning out of workings, and through having to leave "top" coal underground. The diffi culties from spontaneous combustion are being overcome as the result of scientific enquiry. The loss through leaving top coal as being too poor in quality to work will be met by the creation of a market due to the advent of low-temperature carbonization and its use of coal in a pulverized form (see article on PULVERIZED