Cooling Systems

COOLING SYSTEMS. In certain industrial processes cool ing has to be effected to render the working of an engine or machine practicable. All the internal-combustion engines generate such heat in the cylinder that unless cooled the lubricating oil would burn up, pistons and other parts would seize, and unequal expansions would create difficulties. Air cooling by means of fins, though adopted in motor-cycles and some aero-engines, has as yet been adopted by only a few motor-cars.

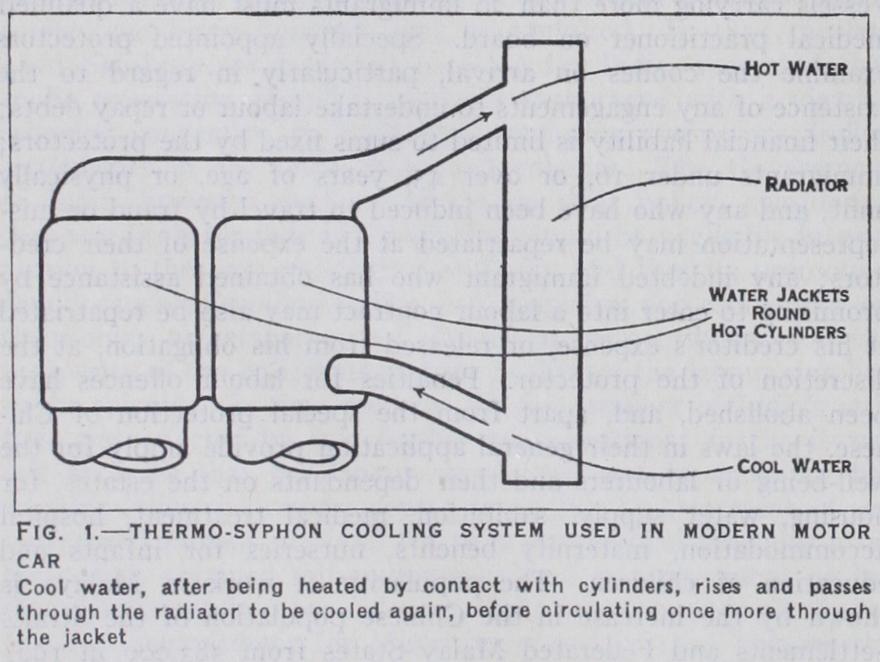

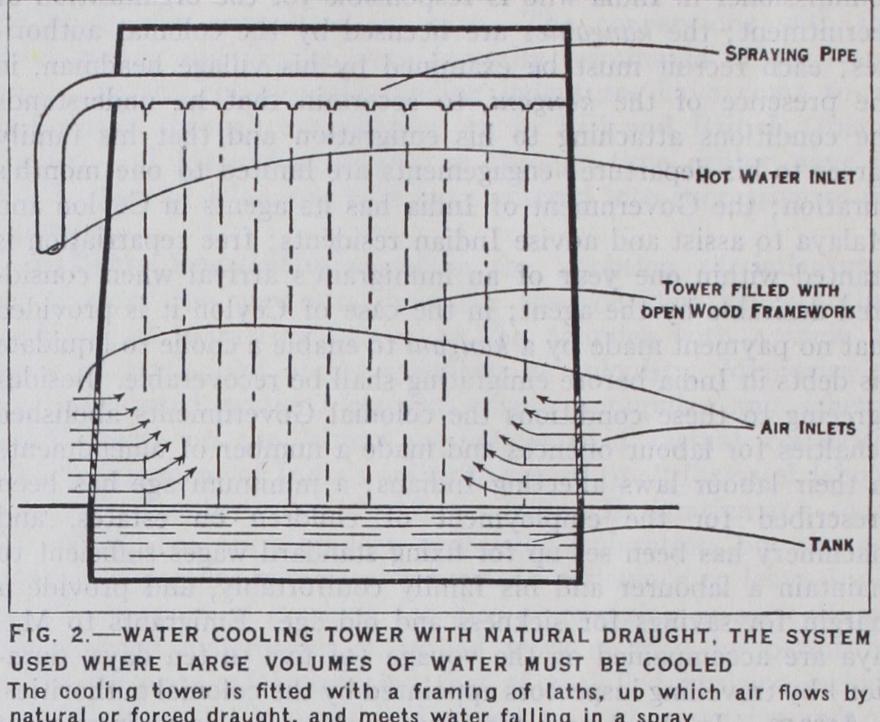

In the water cooling, the most suitable system, a jacket is cast around the cylinders, or made separately from thin sheet in aero engines. Two systems, the thermo-syphon and the pump are in use for passing the water through a radiator, which exposes it to large ,cooling surfaces, past which air is drawn by a fan. In the thermo-syphon method, the hot water from the jacket rises to the top of the radiator and, becoming cooled, sinks to the bottom and flows again to the jacket as illustrated in fig. 1. Refinements which assist in maintaining the required temperature in spite of weather and running conditions are the radiator shutter, adjusted over part of the radiator and the thermostat, which automatically operates the shutter. In large gas and Diesel engines the piston cannot suffi ciently be cooled by the transmission of heat into the cylinder walls, consequently a hollow water-cooled piston is used. Either pump or thermo-syphon flow is employed for these engines. Among other machinery that requires cooling are the cylinders for compressing air or ammonia, and parts of furnaces, such as tuyeres and hearth-jackets, which would otherwise rapidly burn away. Shaft and other bearings may have a much increased flow of oil, beyond that actually necessary for lubrication, if the speed is high or the shafts are big, or they may have water-cooling pas sages in the bearings. When a cooler deals with the oil in its course of circulation it may be of air-cooled pattern for aero engines, or water-cooled in other instances. The condenser is a specimen of cooling apparatus for steam, gas, ammonia, or carbon dioxide, and there are also the cold air and brine circulating sys tems around cold stores. Water has to be cooled in large volumes in several classes of plant, including condensing equipments and large internal-combustion engines. There are three methods em ploying, severally, a large reservoir, into which the water goes and cools by the surface area, a smaller pond with spraying devices, and a cooling tower filled with a framing of laths, up which air flows by natural or forced draught and meets the water falling in a finely divided state as shown in fig. 2. The spray pond has the water sprayed through a series of nozzles out over the water, the cooling effect being due to the water going up in the air in a finely atomized state.

Several schemes for cooling are to be found in electrical ap paratus to check injurious rises in temperature. In motors, gen erators, transformers, etc., care is taken to provide paths for free circulation of either air or oil as near as possible to the points where the heat is generated. Small transformers depend on natural air circulation, while others are mounted in tanks filled with in sulating oil and are self cooling by means of tubes or radiators. Forced cooling is essential for large transformers, with air sup plied by a fan, or water passed through piping in the oil, or the oil itself being cooled. Small and medium sizes of motors and gener ators are cooled by a fan. For large units a closed system of cool ing is preferable, as it avoids the dust present in supplies of air drawn from outside.

Heat generated in metal-working processes, such as turning, drilling, milling and grinding, must be dealt with by copious flood ing with oil, water or compound, otherwise the tools would not endure and the work would be roughened and warped.