Artificial Silk in the Cotton Industry

ARTIFICIAL SILK IN THE COTTON INDUSTRY When, after the World War, the artificial silk industry devel oped very rapidly, there were some who wondered whether the older textiles were faced by a new and serious rival. Many looms in the cotton industry have gone over to the weaving of fabrics consisting wholly of artificial silk, but a considerable manufac ture has also been developed in cotton and artificial silk mixtures of all kinds. The use of artificial silk yarns, whether alone in the loom or with cotton yarns, has been associated with difficulties which the manufacturer previously handling only cotton had not been compelled to face, difficulties arising mainly out of the struc ture of the new fibre, which, unlike cotton, consists of a number of fine, continuous and separate filaments of indefinite length. (See SILK, ARTIFICIAL.) Properties of Artificial Silk.—Artificial silk lacks that elas ticity and resilience which the natural fibres possess, nor is it capable of bearing the same strain and friction. It requires, therefore, more careful handling not only on the loom itself also in the preliminary stages such as winding and warping. Lan cashire manufacturers, however, were accustomed to handling a more robust fibre than this, and the development of a technique more suited to the fibre they were introducing necessarily took time. It was not at once seen that looms must be more carefully tuned, that their speeds must be modified, that jolting and vibra tion must be cut down to a minimum, and that bobbins and spindles in the winding departments must be made to run with considerably more smoothness and accuracy than was considered necessary for cotton. Ideas such as, for example, lining the shuttle with fur or velvet, or of covering the race-board of the loom with some kind of soft material only came gradually. They were the result of individual experiment and trial.

It was not merely the winder and weaver who found themselves faced with new problems. The use of artificial silk brought prob lems to almost the whole of the industry, including both finisher and designer. Chief amongst the problems facing the finisher was the question of uniform dyeing, while the fact that the ten sile strength of the artificial silk fibre, when wet, is extremely low, added further to his difficulties. The main problem of the de signer was that of incorporating threads of artificial silk, which give sheen and brilliance, but which, being smooth and metallic and lying closer together than the cotton threads, are liable to stand out too vividly and harshly.

By 1928, however, the period of building up a trade technique may be said to have been passed. While cotton manufacturers were growing more adept in the using of artificial silk, the makers were improving and cheapening the fibre. The two forces have thus worked in the same direction and it may reasonably be expected that its use will be extended in the future. Artificial silk fabrics have made a definite hold for themselves on the public fancy and artificial silk improves the appearance of cotton fabrics. Artificial silk has made its way into almost the whole range of fabrics the cotton industry has known, from piece goods in which a few artificial silk stripes are included for their colour and effect, and dress materials of all kinds, brocades and furnishings, to an at tempt to imitate crepe de Chine. Mainly viscose silk has been employed, but use has also been made of other types, e.g., acetate silk, because of the more varied dyed effects which its use makes possible.

A Staple Yarn of Artificial Silk.

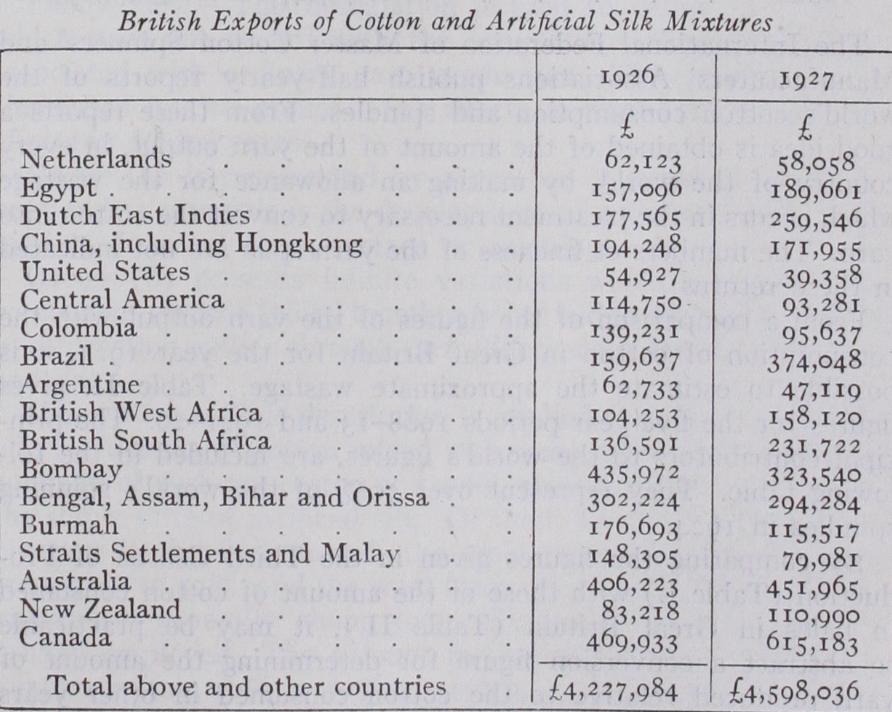

Constant experiment and refinement is going on. The most important development may pos sibly be a staple fibre of artificial silk. Staple fibre yarn is to be distinguished from the more usual type by the fact that it con sists of a thread prepared in much the same way as spun silk and cotton yarns. It is not a recent idea in itself, but it is preg nant with possibilities. Its chief merit as a fibre would seem to be that, although lacking, to some extent, the lustre of the ordi nary yarn, it is softer and warmer to wear than is the latter, and that it opens up the possibility of a blended yarn of artificial silk and cotton. Few spinners have, as yet, gone over to the working up of a staple artificial silk yarn, but it is known that a good deal of tentative experiment has been going on. How far this will be successful and what modifications of existing spinning machinery will have to be made before a staple yarn can be spun on a com petitive and commercial scale time alone can tell.It is difficult to say to what extent important changes have oc curred. The first indication of any considerable use of artificial silk in the British cotton trade is to be found in the trade returns showing the exports of cotton and artificial silk mixtures. The fol lowing table shows the total exports for 1926 and 1927.

The returns on the schedules of the British census of produc tion of 1924 for the weaving branch were as follow:— Artificial Silk Goods Other Than Apparel Net selling value.

(a) Piece goods made wholly from artificial silk ing plushes) 53,000 (b) Other sorts . . . . . . . . 338,000 It is generally accepted, however, that, after ranking, up to 1924, quite low in the list of consumers of artificial silk. Lanca shire has since jumped well to the front ; in this connection it may be noted that the Shirley institute, owing to increasing en quiries from its members, proposed setting up a department to work entirely on problems connected with artificial silk. Such a step is of great significance. (See also SILK FABRICS, ARTIFICIAL.) (E. AL.) Examination of the figures given in Table II. discloses that the fluctuations in the output of yarn changed very substantially in the period 1921-26 as compared with that of 1908-13; the figures are as follow :—