Cotton-Ginning Machinery

COTTON-GINNING MACHINERY Ginning is the process of separating the cotton fibres adhering to the seed for the conversion of the cotton into a continuous thread. The methods employed vary according to the locality and type of cotton cultivated. The earliest method, essentially manual, was discarded in favour of the more expeditious Indian "churka" about 30o B.C. This most primitive machine, which still finds considerable application in spite of a low productive capacity of approximately 5 lb. of lint per day, consists of two wooden rollers fixed in a frame and revolving in contact. The seed cotton is fed into these rollers, the lint or fibres being drawn through and the seeds remaining behind. For short and medium stapled cottons, or cottons adhering tenaciously to the seed, the most favoured ma chine is the saw gin. This machine, which differs very appreciably from the various types of roller gins, has been the subject of many improvements since its introduction in 1792 by Eli Whitney, of Massachusetts.

The Saw Gin.

There are two general types of saw gins : (a) the plain type which gins only clean seed cotton that is free from bolls and trash, and is the original type of gin used; (b) the huller gin which separates the seed cotton from the bolls, burrs, leaf, dirt and other foreign substances in a front lower roll box, and then carries the seed cotton into an upper roll box where it sep arates the lint from the seed, thus performing a double ginning operation. The main working parts in both types of gins are the saws cylinder, roll box and means of removing the lint from the saw teeth after separation from the seed. The plain gin (fig. 20) consists of from 6o to 7o saws which are mounted on a shaft and revolve between the interstices of iron grids; against the grids the seed cotton is held whilst the fibres are drawn through, the seeds being left behind. The operation is as follows : seed cotton is conveyed into the feeder hopper and then carried by a lattice to a spiked roller that regulates the seed supply to the hopper or roll box. Whilst in the roll box the cotton is engaged by the teeth of the saws and drawn through the grids, which are set too close to permit the passage of the seeds. The cotton lint is next removed from the saws by a rotating brush which, on account of its higher surface speed, performs a wiping action on the saw teeth. After this removal the cotton lint is drawn through a flue to the surface of a perforated cage by pneumatic action, subsequently to pass between the cage and cage roller and out of the machine to the press box. The discovery that the air blast generated by the brushes played such an important part in re moving the lint from the saws eventually led to the introduction of the pneumatic or air blast gin—a machine in which the lint is removed from the saws by an air blast system instead of by a brush, thereby permitting a higher speed of the saws cylinder and a consequent increase in the productive capacity of the ma chine. The operation of the huller gin is very similar to that of the plain gin, in that the saws cylinder and the method of re moving the lint therefrom are the same. The roll box construc tion is also the same, except that there is an additional huller roll box in front of the ginning roll box.

From Field to Ginnery.

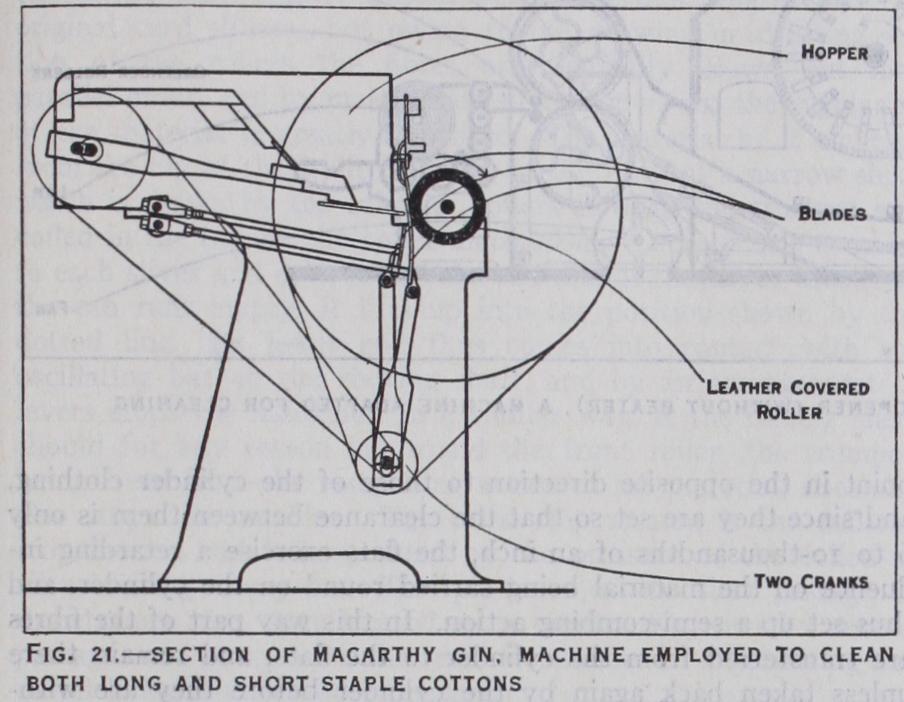

The seed cotton is brought to the ginnery in quantities of I,600 lb. when clean picked, and of 2,000 to 2,200 lb. when gathered or grabbed. When ginned there will be a finished bale weighing about 500 lb. and i,o5o lb. of cotton seed, the remainder being refuse such as trash, hulls, dirt and other foreign substances. The transportation of the seed cotton from the cotton fields to the ginnery usually takes place in open carts or wagons, from which it is drawn by a large pneumatic suction tube. In the course of its subsequent travel the cotton is carried through a cleaner, where it is agitated on a grid to remove foreign matter; thence passing to an elevating system where the air is separated from it and the cotton dropped into the gin feeders. If the cotton is clean picked it can be delivered direct to the ginning roll box in a plain gin ; but if gathered or grabbed it will con tain hulls, etc., and should be delivered to a huller roll box. The seeds fall from the roll box into a seed conveyor, from which they are delivered to the customer's seed box or into a storage house. When several machines are operating they are usually arranged in the form of a battery, and instead of each machine having its own condenser, each machine delivers the ginned cotton into a trunk, through which it is blown to a single condenser which, in turn, delivers it to the baling press.The only other type of gin in extensive use is the Macarthy gin (fig. 21) which is employed in the cleaning of both long and short stapled cottons. The fibres are drawn by a leather covered roller over the edge of a fixed steel blade or doctor knife, which is tangential to the roller. Two cranks move two other blades up and down, placed just behind and parallel to the fixed blade. The seed cotton is thrown into the hopper and the fibres are drawn by the roller until the beaters strike them off but permit the fibres to go forward with the roller. The methods whereby the cotton is delivered to and removed from the Macarthy gins differ from those adopted in the case of the saw gins, for instead of pneumatic means being applied, manual labour is generally em ployed. Efforts continue to be made to improve not only the production of cotton gins, but also the cleaning capacity, especially in those localities where picking is done by "snapping" and "sledding" (International Cotton Bulletin, vol. vi., No. 21) . The liability of damage to both fibre and grade is of the greater im portance and it is essential that every attention be paid to the working condition of cotton gins.