Floating Docks

FLOATING DOCKS A floating dock is a steel, iron or timber floating construction designed to raise ships out of the water, that their under-water portions may be inspected and, if need be, painted or repaired. The earliest known form was evolved by an English captain during the reign of Peter the Great in the harbour of Cronstadt. His ship being in need of repairs, and no facilities being available, he an old hulk which he gutted completely, and fitted with a water tight gate at the stern. He then berthed his ship inside the hollow shell thus formed and, after closing the gate, pumped out the water remaining inside. He was thus able to repair his own ship in the dry. This type of dock continued in use for the next 15o years, and is known as a "camel" dock, from the name of the Cronstadt hulk.

The first obvious improvement was to construct a dock spe cially for the purpose instead of utilizing a hulk. A dock of essen tially this type was built by Christopher Watson in 1785 at Rotherhithe. The useful life of timber docks is surprisingly long. An engraving of this dock was made, dated 1829, or no less than 44 years after the dock was built, and it is not known how many years of life it had after this was first built and used.

The next step in the evolution of the modern floating dock was to make the walls and bottom hol low, and thus buoyant. As early as 1809 a patent was taken out for a hollow iron dock, but there the matter rested for many years.

The first hollow docks were constructed of timber in the United States, the earliest of any note being that in the navy yard at Portsmouth, Maine, which was built in 1848. These early timber docks suffered from the fact that they would not readily sink low enough to allow a ship to enter them. The walls therefore were fitted with a deck inside them above the normal water line forming chambers into which water could be pumped in addition to the amount which could flow in by gravity, thus overcoming the natural buoyancy of the timber. This drawback ceased to exist when iron was substituted for wood in the construction of the hull, but the same system of pumping water into the walls was followed for some years.

In 1866 iron docks began to be freely built from the designs of George Banks Rennie, James Campbell, and others, which were worked at Cartagena, Saigon, Callao, Bermuda, and other places. The most notable of these was Campbell's dock at Bermuda, then and for many years the largest floating dock in the world. It had a length of 381 f t. and a lifting power of io,000 tons, and was in use up to the year 1905. In addition to the buoyancy due to the fact that the structure of the dock was hollow, further lifting power was obtained by means of gates, wl ich could be put in place at each end when the ship was partly lifted, water being pumped out from the space between them exactly as was done in the very earliest type of floating dock.

In 1876 a new problem in docking ships was presented by the construction of Admiral Popoff's circular ironclads in the Black sea. The diameter of the largest of these was 12oft., and no dock in the world had a width of entrance enough to admit a vessel of such beam. This problem was solved by Clark and Standfield, who devised a floating dock with only one side, the loss of ity entailed by the absence of the other side being compensated for by a floating outrigger attached to the dock by two sets of hinged parallel arms. This was called a "depositing" dock. The pontoon or horizontal portion of the dock, upon which the ship rested, instead of being a tinuous platform, consisted of a series of fingers with a space of 5ft. between them, each finger being 72ft. long. By detaching some of these from the wall of the dock and attaching them to the ends of others, a platform wide could be made, and upon this the circular ironclads were lifted. A staging had been built along the shore, with the spacing of the grids corresponding to the distance between the fingers of the dock, so that by towing the dock with the ship on it sideways to the staging the fingers and the grids were interlaced. If then the dock were lowered, the ship was deposited on the staging, and the dock was free to be towed away to lift another ship and deposit it on a further length of staging. Examples of these depositing docks are still to be found at Nicolaieff, vostok, Barcelona and Kobe. The dock at Kobe was built pally for dealing with immense monoliths of reinforced concrete, which were built on the staging, lifted off by the dock, and towed away to the site of the quay wall, where they were sunk in posi tion, thus allowing the quay wall to be built of blocks weighing upwards of 6,000 tons.

An outcome of the depositing dock was the "off-shore." This is also a single-sided dock, but the pontoon is a continuous struc ture, and the floating outrigger is replaced by braced vertical col umns on shore. Many of these docks have been built, most of them being very rapid in operation.

The most common type of floating dock is the double-sided dock, of which there are many kinds distinguished by the means employed to arrange them for self-docking. It is obvious that a floating iron or steel structure must from time to time be got out of the water for repainting if its life is to be prolonged. As a rule a floating dock is too wide to go into any other dock, even if such be available, so all but the very smallest are designed to be able to lift each portion of themselves out of the water in turn.

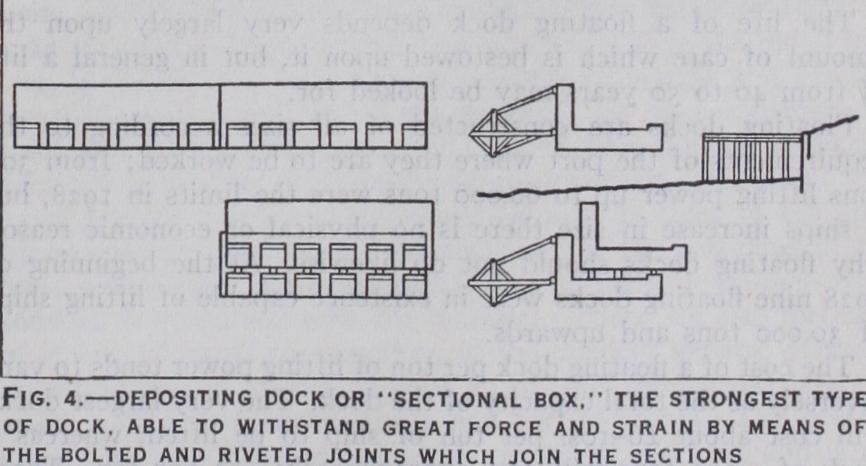

Self-docking Docks.—The earliest of the self-docking docks was the "sectional." In this case the dock was built of a number of separate and independent sections which were held together generally by chains, the length of each section being such that it could be turned sideways and lifted by two other sections. This system has the drawback that it has no longitudinal strength, and the risk of straining the ship by uneven pumping is consider able. Accidents have occurred due to the breaking of the connec tions between the different sections.

A much better form, generally known by the name of its inven tor as the "Rennie" or "sectional pontoon" dock, has the walls continuous, thus forming a stiff girder the whole length of the dock, and the pontoon divided up as in the case of the "sectional" dock, the joint between the walls and pontoons being horizontal. This type of dock has been built to take ships up to 2 5,00o tons, but it is better adapted for smaller sizes, more particularly if they have to be towed across the ocean to their final destination.

The strongest and at the same time the lightest form of self docking dock is known as the "sectional box." This was evolved also by Clark and Standfield, and is the type used by them for the 6o,000-ton dock at Southampton, which was built to take the largest Atlantic liners as well as battleships. It is similar to the "sectional" dock, but the sections are attached together all round their complete profile by bolted joints below the water line and riveted joints with butt covers above it. Thus the dock forms one continuous whole, with very great longitudinal strength to with stand the stresses set up in the structure during the operation of docking a ship, or the much greater stresses which may occur dur ing an ocean voyage. When it is required to self-dock, the joints between the sections are unmade, and the sections successively lifted upon the rest of the dock.

The self-docking of a single-sided dock is very simple. There is a transverse joint at the centre of its length which when unmade enables one half to be lifted, so to speak, on to the lap of the other.

General Description.—A typical modern floating dock may be said to be a large rectangular hollow steel trough. The principal functions of the vertical sides of the trough, which form the walls of the dock, are to give stability to the dock when it is being worked without a ship on it, to contain the machinery required to lift the ship, to form platforms from which to berth the ship, and to give longitudinal strength. The horizontal portion of the trough, or pontoon, forms the platform upon which the ship rests, and provides the buoyancy which lifts the ship out of the water. The pontoon is extensively subdivided by watertight bulkheads to ensure stability, and the walls are also divided, but to a lesser extent.

The underlying principle upon which the working of a floating dock depends is that if, say, a ton is removed from a floating struc ture, that structure exerts an upward pressure of one ton. The main machinery of a floating dock, therefore. consists of a. .7. of centrifugal pumps plar051 al low down airpossille in 7--Le.: toon, and worked by steam, electric or other prime movers, situ ated on the top of the walls; and it is the throiring out of water by these pumps which causes tE=, =.h".7 gradually to the sea. In order that the f:ie kept level.

of the dock has separa.-.

and vah-es. a__ iff_.1 actuating the valves brough-. in the F*. 3 represents two views of ack_ one seen from the end ar.-f oth=:.: a;,7_,,_r if cut in two. The arrar.gt:Ltrit of seen in the left-band view. In tbe '7- 7 is shown an elec-tric which 1,--/ of a.

drives a centrifugal

pt;=_-_p vcated on a r_;-__r_-irox, r--- - full length of the dock Bra7-_-_hfr-.2 are (-7-r_t7 leading to different c- - = 77= • Z through these branch is, r_ -,7• by a valve, the rod actuatEz - - - - 7 of the wall, where it is to a pr - is worked. Th--, a -.fr.:. Issf in of air to trolled from the ‘-alye--=_--)tr.,e. I- -'- 56 of these - • -- On the top of the mo*.or which all the maci-iinery of oip.-_- ated, so that ti-c- 7,-:— lifting a ship T-- - z' touching the - - - z: z a-hich c.a.n be ar. : . 3. 71 3. 7 t -- gether across = " = z t h e drawing it is k_-- ------ the dock_ In 67-'=" - - - - - there is an wall. only one c:rawing ThiS dock is moored to the by of hinged at each en.d, at:, z -o " dock and to dolphins 7_Z 711: Z pre‘-ented by fore and af- chlirzap cme these booms is decked 2-117_: ' ' - as a means of commtmication -'= of the dock_ The following operations are - 2.

a floating dock

Water is a - - c: -" dock until it is deeply z":7 - brought in; (2) ro--.1_ _ pumped out of th-a. it is. on the ship: (4) the E • or - are put - under the bottom of -'- to z--=f+y- 7.-ate- is pumped out of T.-Le th- -eve The life of a feazing dock • -- "- amount of care which is. bestowed Z - I: a of from 4o to years rnay be for.

Floating

docks are constrlic:ed of all sizes _o requirements of the per: w'r_-:-.re are to be worke.f: fr:-.7_ 3:c tons lifting power up to 6:.-.s..coc -;cere the - - -z bu: if ships increase in size there is. n.o -22:nysical or eco- --fason why floating docks should not do likewise. At t1-_- of 192S nine floating dock_s were ir, estence capable of of 3.s.oco tons and upwards.The cost of a floating dock per :on of lifting ;sower =ZS tO varyinversely as the total capacity of the dock. Thf.

will

cost about .t:6-Ics.. per ton of sEp dock of i.000 tons will cost approxima:ely ;77=7 :,77.figures do not include the cost of dredging.

_ _