Electric Cranes and Gantries

ELECTRIC CRANES AND GANTRIES Cranes are lifting machines that move an object in three direc tions at right angles to one another; and in the electric crane each of these movements is carried out by a separate motor and operated by a separate controller, in such a way that all three may be in action at the same time. The problems involved in its design include not only the carrying out of the positive motion, but also the effective stopping of the movement and the lowering of the load at a desired safe speed. Braking thus becomes an important item.

The most common types are jib cranes and girder cranes. For small versions of the latter, the motors are controlled from the floor by means of pendant cords ; but for ordinary sizes, the opera tor travels with the girder in a cab usually suspended from one end. For large varieties, the cab is supported by the carriage itself, which is then termed a "man-trolley." Instead of running along a pair of girders, such a trolley may be arranged to travel on the horizontal members of a gantry, which is supported on two legs having wheels and driving motors, the whole then con stituting an "unloading bridge" ; or it may travel over a special overhead runway about a yard or warehouse. Other variants, such as the hammer-head crane, as well as the portal crane, semi portal crane, etc., are in every-day use.

Motors.

The chief features required of crane motors are the ability to overcome heavy starting torques and to accelerate as quickly as possible; and also preferably to lower the load at a convenient speed, the services of an external friction brake being dispensed with whenever possible. The first group of requirements point to the series D.C. or the slip-ring induction motor as being appropriate, but the second indicate the definite superiority of D.C. working; and where a number of cranes are located close together in a district only served by an A.C. supply, it is a fre quent practice to employ a converting plant for providing them with direct current. A.C. motors with solenoid brakes are, how ever, quite a practicable alternative. For such infrequent duty, "crane-rated" windings are the rule, which are generally designed to carry full load for only half to one hour continuously without over-heating.

Control Gear.

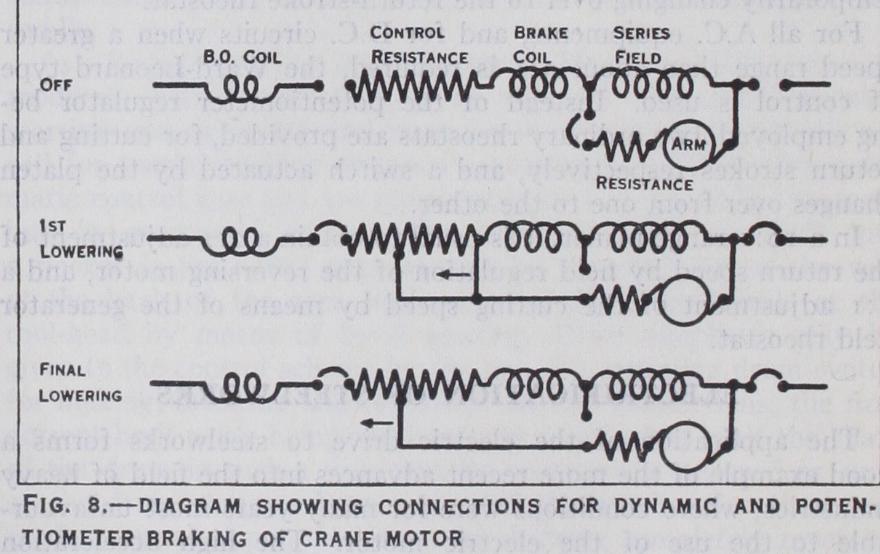

The control gear may be either of the hand operated drum or of the automatic contactor type. The former is the standard for the smaller capacities, but the advantages of automatic working often secure the use of contactor gear for small as well as large models. Whichever type is used, the rule is to render the operator's duties as simple and subconscious as pos sible, in order that he may be able to concentrate almost the whole of his attention upon the movements of the load. What is known as the "sympathetic" arrangement of control levers will be found to assist very greatly towards this end. In this system two of the controllers are so geared together as to be operated by different movements of the same lever; and both levers are so designed that the driver's motions are always in the same direction as those in which he desires the load to travel.No special comment is needed regarding the control of the two horizontal travels, for which ordinary armature or rotor resistance control is employed. Braking is usually effected by "plugging" or reversing the motor through the whole of the control resist ance; and foot brakes may also be used. But the hoisting motor requires quite specialized control when advantage is to be taken of the braking facilities of direct current. Very convenient lower ing characteristics are given by what is called "potentiometer" braking, the principle of which is shown in fig. 8. Here the armature of the series motor is reconnected in shunt with a por tion of the control resistance, so that it behaves similarly to a shunt motor, acting as a generator (and thus developing a nega tive torque) when rotating in the same direction as it did as a motor. The full series of connections is indicated in fig. 8, in which an auxiliary solenoid for releasing a friction brake is also shown. The hoisting is carried out in the usual manner, by cutting out the series resistance. In the "off" position, the armature is reconnected in a closed ring with the field and a resistance, giving ordinary "dynamic" braking for bringing about a stop. For the slowest lowering speed, the potentiometer connection is carried out as in the middle diagram, and the speed is increased by progressively cutting the main resistance into the ring cir cuit and out of circuit with the armature as indicated by the arrows.

For some cranes, such as those used in foundries, very slow speeds and gradual acceleration are needed, and these are ob tained by means of diverter control. Series resistance is used, which is cut out in the usual manner; but for extra low speeds, not only is the whole of this left in circuit, but the armature current is further reduced by diverting current from it through a variable resistance shunt. In one controller type the diverting resistance is varied by a drum, which is mechanically inter locked with the larger so that it cannot be moved unless the main drum is in the "off" position, after which the latter can only be advanced to the first or second steps, while the auxiliary drum cannot be moved to the "off" position until the circuit has been ruptured by the main unit.

Contactor controllers carry out the same routine as the manual type, and their circuits do not call for special comment. What are known as "crane protective panels" are employed with any type of gear, and employ a master contactor controlling the cur rent for all the crane motors. An overload relay is provided for each independent circuit, and one also for the common return lead. An excessive current in any can open the contactor, which is reclosed by a special auxiliary switch or contact convenient to the operator. The chief advantage of this type of overload pro tection is economy of time.