Electrification of Steelworks

ELECTRIFICATION OF STEELWORKS The application of the electric drive to steelworks forms a good example of the more recent advances into the field of heavy industries, where conditions were for many years most unfavour able to the use of the electric motor. The high acceleration required, the violent fluctuation of the load, and the huge power demand, all taxed the mechanical and electrical robustness of the motor to the limit, in a situation where continuity of service was all-important ; while the prevalent high temperatures and the all-pervading grit strongly militated against the durability of insulation and wearing parts. In spite of all these difficulties, electricity has won the day, and steam drive has been forced into obsolescence, by virtue of the developments in control methods that have been described in the first section, aided by the pro duction of the "mill" type of motor.

The chief pieces of steelworks equipment that call for comment are the following: (a) Furnace hoists; (b) main rolling-mill drives—large main rolls, requiring up to about 20,000 h.p.; smaller mills, requiring up to about Soo h.p. ; (c) mill auxiliaries— live rolls, lifting and tilting tables, screw-downs, manipulators, side-guards; (d) transport equipment—various highly developed cranes; (e) other equipment; e.g., hot saws, air compressors, etc.

Motors.

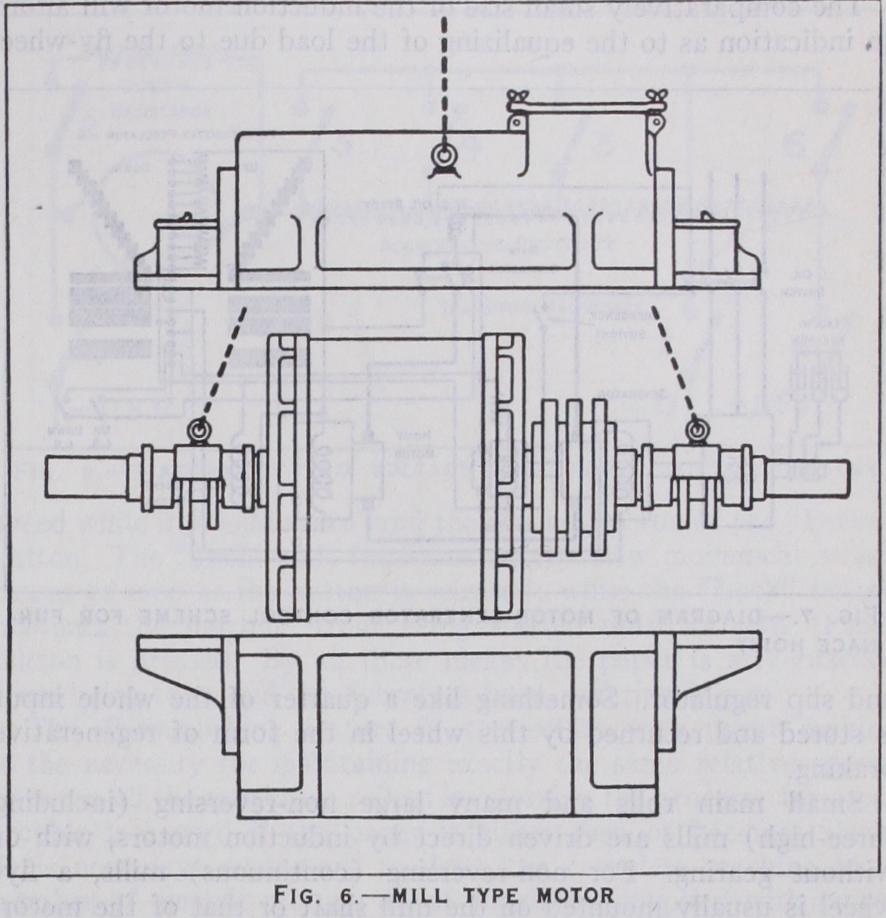

The special motors may be divided into two classes. First, there are the very large units, up to about 20,000 h.p. instantaneous rating, operated by Ilgner sets. These are mostly double-armature machines, being really designed as twinned units with the object of keeping the diameter and therefore the inertia low, to facilitate quick reversal. As regards shaft diameter and mechanical design generally, they are made robust ; but the treatment accorded to them is not so severe as in the case of the smaller auxiliaries. Secondly, there are the motors used for the latter purpose, which are designed to withstand the roughest mechanical and electrical conditions experienced in any situation. The "mill type," illustrated in fig. 6, was developed for this purpose, and is made for both D.C. and A.C. It is totally enclosed, and the frame is split in halves horizontally to facilitate rapid opening up. The shaft is made to project from each bearing, so that the rotor or the whole machine may be reversed end wise if the driving end should be twisted off. Full use has been made of eye-bolts on bearing bushes and frame to render the most rapid refitting possible.

Control Gear.

Ward-Leonard (including Ilgner) and con tactor control divide the field between them, and are designed for operation by unskilled attendants whose faculties are con centrated on the actual work that is in progress. The various types of installation are most conveniently dealt with in connec tion with the equipment to be driven.

Furnace Hoists.

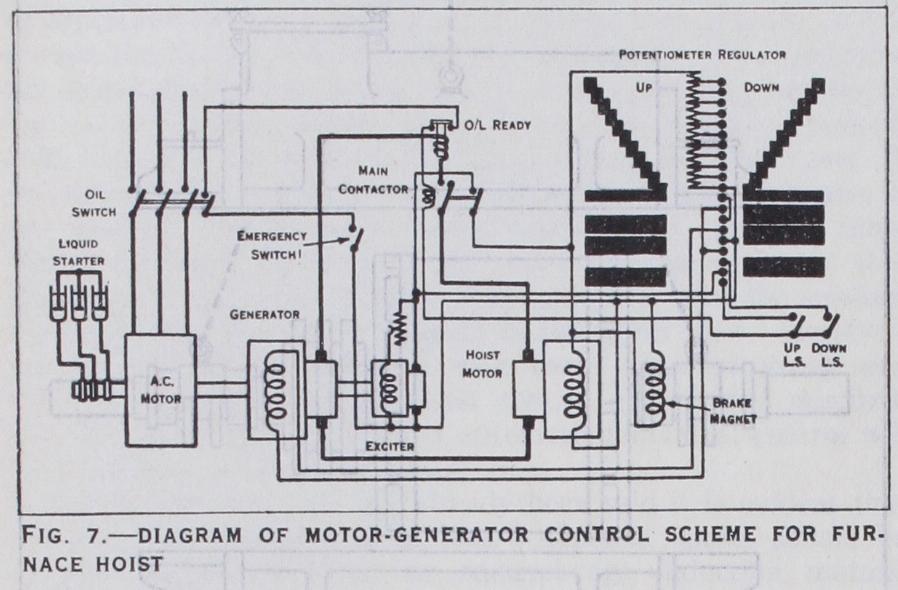

Simple operation of the push-button or pull-lever type and accurate decking are the essentials for fur nace hoist control, the conditions for which are less strenuous than in the actual mill. The power required is in the vicinity of ioo h.p., and is provided by compound motors with "straight" con tactor control gear for D.C. circuits, and by Ward-Leonard gear when the supply is A.C. A typical A.C. equipment is illustrated in fig. 7. It will suffice to explain that the regulator is operated by one of two cams, for up and down motions respectively, and the travel is started by changing the drum over from one cam to the other by means of a lever.

Rolling Mills.

Large reversing main rolls are driven by Ilgner gear, the scheme being broadly as in fig. 7, with the addi tion of a slip regulator and fly-wheel to the induction motor. Particulars of a typical large set are as follows: Mill (reversing) motor-6,000 to i8,000 h.p. at 1,600 volts, twin-armature type. Generators—three in series, 4,500 kw. total continuous rating. Induction motor-3,000 h.p., 2,75o volts, three-phase.The comparatively small size of the induction motor will afford an indication as to the equalizing of the load due to the fly-wheel and slip regulator. Something like a quarter of the whole input is stored and returned by this wheel in the form of regenerative braking.

Small main rolls and many large non-reversing (including three-high) mills are driven direct by induction motors, with or without gearing. For non-reversing (continuous) mills, a fly wheel is usually mounted on the mill shaft or that of the motor. The control gear is of the contactor type, with slip-regulator if a fly-wheel is employed.

Auxiliaries.--It is for the drive of the auxiliaries, requiring from 5o to zoo h.p., that the mill type of motor was developed. The policy as to control gear is to keep it as simple as possible, and series or induction motors are in most general use, with plain reversing contactor equipment, braking being typically by plug ging. For screw-downs and similar equipment, a solenoid brake may be added. Lifting or tilting tables are operated by a non reversing motor through the medium of cranks, halting auto matically at either end of the stroke.

Cranes and Machine Tools--Except for the general need for robustness and for protection against grit, etc., the drive of steel works cranes and machine tools does not differ in principle from standard machine-shop practice.