Hydroelectric Generation

HYDROELECTRIC GENERATION The extent to which the water powers of the world have been investigated and developed since 1910 forms one of the striking engineering features of the period. Although falling or flowing water formed the earliest of the natural sources of energy to be utilized for providing power, some two-thirds of the water power at present in use has been developed since 191 o. The reasons for this are partly technical and partly economic. The technical de velopment of the hydraulic turbine has rendered it possible to utilize any head from Io feet to 5,00o feet with a high degree of efficiency and at such speeds of rotation as enable a reasonably cheap electric generator to be used. The development of high ten sion transmission at pressures up to 2 20,000 volts, has enabled the energy to be transmitted efficiently for considerable distances—up to 200 or 30o m. in some cases—so that it has become commer cially possible to develop large water powers at sites far remote from any centre of industrial activity, and to transmit the energy for long distances to the nearest convenient centre. Technical de velopments in electrochemical, electro-physical and electro metallurgical processes, most of which require relatively large amounts of cheap electrical energy, have created a demand for large blocks of cheap power which can, under favourable circum stances, be satisfied more readily from a water power installation than from any other source. For a water power installation to be economically possible, it must in general be able to generate en ergy more cheaply than a steam plant. Even in countries which have an adequate supply of cheap fuel this is possible in many in stances, while in countries which are normally dependent on im ported fuel and which are favourably circumstanced as regards water power, the latter source of energy becomes all important.

The urgent demand for energy to supply the abnormal require ments of the war period, combined with the increased cost of fuel, was responsible for an unprecedented rate of development in many countries—notably in France, Italy and Canada. In France about 3,000,00o water h.p. is now developed as compared with 750,00o h.p. in 1914. In Italy the total output will shortly amount to 3,000,00o h.p., while the installed capacity of the water power plants in Canada is now almost 5,000,000 h.p. Japan which only lately began to investigate its water powers has, since 1916, de veloped over 1,200,000 h.p. In most of the other countries of the world, and notably in the U.S.A., Spain, Sweden, India, Bra zil and Chile, hydro-electric development is actively taking place, at a rate which shows little sign of slackening in the near future.

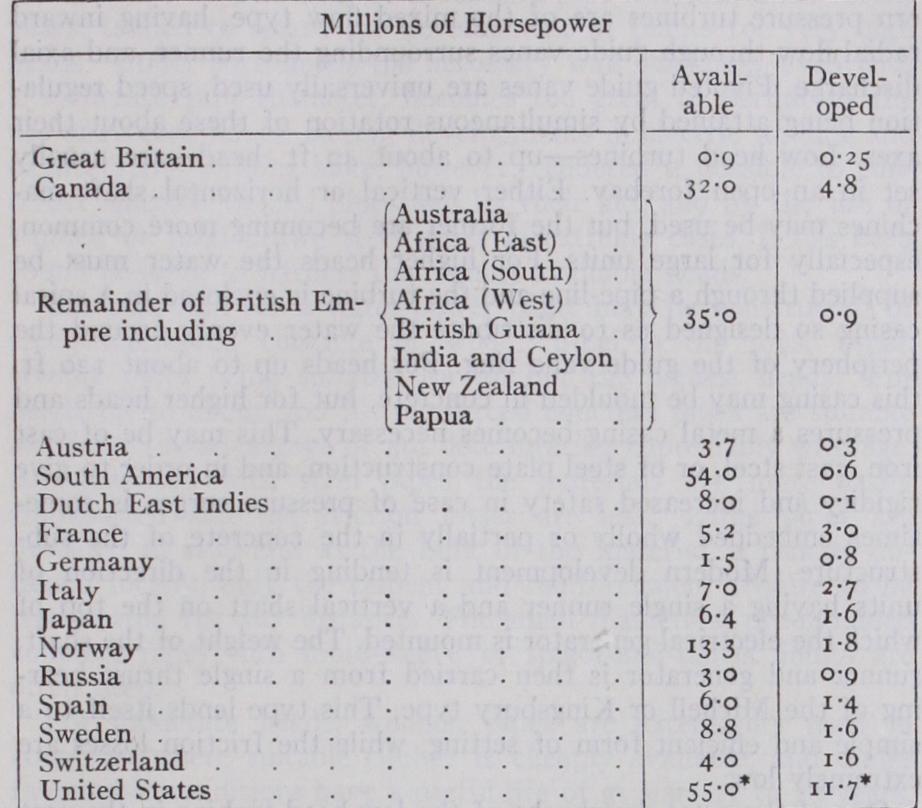

Available Water Power.—While any estimate of available water power can only be of the most approximate kind, the fol lowing table affords some indication of the amount of water power respectively available and developed in some of the chief countries of the world.

*Estimated on the basis of steam-flow available so per cent. of the time.

From these figures it appears that some 240,000,000 h.p. is available, of which approximately 30,000,00o is at present de veloped or in course of development.

Uses of Hydro-electric Energy.—While a large proportion of the energy developed from water power is utilized for indus trial purposes and for lighting and traction, an increasing propor tion is being used for pulp and paper making and electrochemical and electro-metallurgical processes ; indeed the chief outlet for hydro-electric power in the near future is likely to be in connec tion with such processes and, probably, railroad electrification. The amount of power already used in these ways is large. Thus in the U.S.A. and Canada alone the power absorbed in the pulp and paper industry is approximately 2,750,000 h.p. Again, the world's production of calcium carbide requires some 500,000 h.p. and when it is remembered that such products as aluminium, carborundum, chromium, cyanamide, caustic soda, chlorates, mag nesium, phosphorus and silicon are only rendered commercially possible by such processes, it will be realized that the future de mand for energy for their manufacture is certain to be large. Ni trogen fixation is also likely to make considerable demands. In Norway alone some 400,000 h.p. is available for this purpose, and in view of the rapid depletion of the natural nitrate deposits, from which four-fifths of the world's nitrogen consumption has hitherto been supplied, and of the diminution in fertility of many of the great wheat and cotton growing areas of the world, the produc tion of artificial fertilizers by one or other system of nitrogen fixation must, in the near future, become a question of great importance.

The electrification of railroads has made rapid strides of recent years, and while railroad electrification is not necessarily de pendent on hydro-electric power, it is noteworthy that all the large trunk line electrification systems are operated from hydro electric stations, except certain developments in the eastern part of the United States. In the United States some 3,500 m. of track have been electrified, while the Chicago, Milwaukee, St. Paul & Pacific has an electrified section of 85o m. which is sup plied from hydro-electric stations. In France, much of the track of the Compagnie du Midi has been electrified with the aid of the water power of the Pyrenees, and it is anticipated that the whole system of about 3,00o km. will be electrified within io years. The plants supplying these lines have a capacity of close upon 300,00o h.p. The Orleans railway has a scheme for elec trifying some 3,00o km. of its line, part of which is to be sup plied from hydro-electric stations having a capacity of about 210,000 h.p.

In Austria some 2,000 km. of line is in process of electrification, and in Germany about 1,200 km. is now electrified, the power in each case coming mainly from hydro-electric stations. The Swiss railways are supplied from hydraulic stations built mainly for this purpose, and the ultimate programme of development com prises the electrification of the whole system by this means. Spain, Mexico, Brazil, Sweden and Japan also have a number of such schemes in hand, and these and similar developments will provide a very large field for the utilization of water power where this is available.

Much energy is now being utilized in the United States of America for purely agricultural purposes. In California, for example, there is in effect one vast system of electrical supply extending over a distance of Boo m. with 7,200 m. of high-tension transmission lines. This is fed from 114 hydro-electric stations interconnected with 3o steam plants, to give a total installation of 2,510,000 kw. A large proportion of this power is used in agriculture, a survey having shown a connected agricultural power load of nearly 636,00o h.p. in California in 1925. The Californian rice industry is almost wholly dependent on irrigation made possi ble by electric pumping, whilst many of the mechanical processes involved in farming are being performed by electric power.

In Sweden it is estimated that the power absorbed in the farm ing industry is now about 270,000 kw. The annual consumption is about 120 million kwh. or approximately 30% of the output of the State hydro-electric stations.

The economic development of many of the tropical depend encies of the British empire, whose latent wealth is practically untapped, is directly interconnected with the development of their water-power resources. Not only would an abundant supply of such power enable railroads to be operated, irrigation schemes to be set on foot, and mineral deposits to be tapped and worked, but it would go far toward solving the labour problem which promises to be one of some difficulty in the future.

While those outlets for electrical energy which are now in sight promise to absorb all the energy which can be cheaply de veloped for many years to come, there are many other probable directions in which such energy might find a new and profitable outlet. Among these may be mentioned the purification of municipal water supplies; the dehydration of food products; and the preservation of timber.

Layout of Hydro-electric Schemes.—The possibilities of hydro-electric development in any country depend essentially on its physical characteristics. Adequate rainfall is the first essen tial. A boldly contoured region has many advantages, in that it is often possible to find elevated sites at which water may be col lected and stored in close proximity to sites at a much lower elevation, to which the water may be led and utilized under the head corresponding to the difference between the two levels.

Since the horse-power which can be developed by each cubic foot of water depends directly on the working head, a high head in stallation requires a much smaller volume of water than a low head installation of the same power, so that the pipe lines and the turbines are smaller and the installation is in general cheaper. Moreover, the volume of water which requires to be stored in wet weather in order to enable continuous operation to be carried out throughout the year is also smaller, and a comparatively small reservoir will often enable sufficient storage to be obtained at a reasonable cost.

For these reasons such countries as Norway, France, Switzer land and Italy, which have mountainous regions subject to heavy rainfall in close proximity to industrial regions capable of absorb ing large amounts of electrical energy, are very favourably cir cumstanced for hydro-electric development. One development in Switzerland—at Lac Fully—utilizes the highest head on record. This is 5,412 feet, and the pressure of the water in the pipe line adjacent to the power house is 2,26o lb. per sq. inch.

In these high head schemes the water is normally brought from the supply reservoir through an open canal at a very flat gradient to a small chamber or forebay on the hillside above the power house, whence a short steep pipe line conveys it to the turbines. In one high head type, if a sudden closure of the turbine gates occurs, the water momentum in the pressure tunnel is absorbed in causing a surge up a surge tank, instead of in producing a heavy pressure wave in the pipe line. A noteworthy development of this general type is to be found in connection with the installations sup plying electric power to Bombay from hydro-electric stations drawing their water from reservoirs on the eastern side of the Ghats.

But although high head sites offer many advantages, they are not essential for the successful development of hydro-electric energy. The great majority of those water powers of the world which are in reasonably close proximity to industrial communities, are indeed in regions in which the gradients are medium, and the aggregate power developed from medium and low heads is vastly greater than that from high head installation.

Low head schemes, utilizing heads up to 4o or 5o feet, are usually located on rivers in which the gradient is small. In some cases a natural head is available owing to the presence of rapids or waterfalls, the water being diverted and led through a flume or canal to the turbines from which it is discharged into the low-level reach of the river. In other cases it is necessary to make an arti ficial head by means of a dam. A dam, by raising the natural level of the water, provides a certain amount of storage, but seldom more than is sufficient to store the night flow of the river for use during the day. A river scheme of this type can therefore only give a continuous output equal to the dry weather flow of the river. It is usually however, found economically sound to install hydraulic plant of a capacity greater than that correspond ing to the minimum dry weather flow, and to install, as an essential part of the scheme, a steam plant capable of maintaining the out put when the supply of water is inadequate.

Various types of low head development are adopted as they best fit the conditions encountered at the power site. Where a dam is built, the power house is often constructed on one flank of the dam with a short head race or tail race as is most convenient, and the dam itself is used as a spillway over which excess water is discharged in times of flood. Where the river flows in a narrow and steep gorge the powerhouse may sometimes with advantage be constructed in the dam itself, which now consists of a hollow reinforced concrete structure. Where the river forms a long bend, it is often possible to cut across the neck of the bend and to utilize the head between the two points.

In medium head schemes—utilizing between 4o and zoo ft. head—the layout is usually similar in broad outline to those involving either high or low heads. Where such a scheme involves the use of a long closed supply pipe to the turbines, having only a small gradient, somewhat special treatment, however, becomes necessary. Owing to the large inertia of the column of water in the pipe line, any sudden demand for water caused by opening the turbine gates on an increasing load causes a relatively large drop of pressure at the turbines, which renders governing very difficult. To reduce this difficulty, a surge tank is fitted to the pipe line at a point as near to the turbines as possible.

Turbines.

With the exception of the new low-head propeller type turbines, the inward flow pressure turbine and the Pelton wheel are the only types of turbine used in modern hydro-electric schemes of any size. The type to be adopted depends largely on the available head. The Pelton wheel is a slower running machine than the pressure turbine and is therefore better fitted for very high heads. It has the further advantage for such heads, that since the water is discharged through one—or at the most two—nozzles, these may be of reasonable size when dealing with the small vol umes of water normally available in high head schemes. The press ure turbine on the other hand with its full peripheral admission of water is well adapted to utilize the large volumes necessary in low head schemes, and its higher speed of rotation is also a great advantage in low and medium head plants, in enabling the cost of the electrical generators to be reduced. Broadly speaking, the Pel ton wheel is more suitable for heads above about 700 ft.; the pressure turbine for heads below about 250 ft. in small units and below about 500 ft. in large units; while over the intermediate range of heads much depends upon the size of the units and the special circumstances.With the exception of the new propeller-type turbines, all mod ern pressure turbines are of the mixed flow type, having inward radial flow through guide vanes surrounding the runner, and axial discharge. Pivoted guide vanes are universally used, speed regula tion being attained by simultaneous rotation of these about their axes. Low head turbines—up to about 4o ft. head—are usually set in an open forebay. Either vertical or horizontal shaft ma chines may be used, but the former are becoming more common, especially for large units. For higher heads the water must be supplied through a pipe-line and the turbine is enclosed in a spiral casing so designed as to distribute the water evenly around the periphery of the guide vane ring. For heads up to about i 20 ft. this casing may be moulded in concrete, but for higher heads and pressures a metal casing becomes necessary. This may be of cast iron, cast steel, or of steel plate construction, and in order to give rigidity and increased safety in case of pressure surges is some times embedded wholly or partially in the concrete of the sub structure. Modern development is tending in the direction of units having a single runner and a vertical shaft on the top of which the electrical generator is mounted. The weight of the shaft, runner and generator is then carried from a single thrust bear ing of the Michell or Kingsbury type. This type lends itself to a simple and efficient form of setting, while the friction losses are extremely low.

One of the great drawbacks of the low head turbine in the past has been its relatively slow speed of rotation, which necessitated either a slow speed and costly generator or expensive gearing. As a result of experiment it has, however, been possible so to modify the form of the runner as greatly to increase the speed of rotation under a given head without seriously reducing the efficiency.

Such runners are characterized by their small number of vanes —often not more than four being used—which approximate in form to those of a marine propeller. In one of the latest types, the Kaplan, the vanes are capable of rotation about their own axes so as to enable the vane angles to be adjusted to suit the varying flow of water at part loads. Further developments in the direction of increasing the speed are in active progress and promise to give important results. At the present time, however, turbines are in existence which are capable of efficient operation at speeds at least three times as great as would have been thought possible io years ago.

The pressure turbine is now built in units capable of developing upwards of ioo,000 h.p., and this size could readily be increased if necessary. If well-designed and installed in a suitable setting the efficiencies are remarkably high. Efficiencies of 93% have been obtained on tests of vertical shaft turbines at Niagara and values approximating 90% are quite common. In a medium head plant the following are typical values : Pelton wheels are almost invariably built as horizontal shaft units with one or two nozzles, thus far in sizes up to 40,000 kilo-watts. Speed regulation is usually performed by a deflector which cuts off the jet from the wheel, acting in conjunction with a central needle or spear which slowly reduces the size of the jet while the deflector returns to its original position. The mechanism is operated by a relay cylinder supplied with pres sure water or oil through a pilot valve actuated by the governor. In a well-designed plant the instantaneous speed variation cor responding to a sudden application of full load should not exceed 12 to 15%. The difference between the initial and final steady speeds should not exceed 2% between full load and no load.

At constant speed the efficiency of a Pelton wheel falls off com paratively slowly as the load is diminished. A well-designed wheel Pipe-lines.—The lack of a suitable pipe-line has, until recent years, tended to retard the development of plants for very high heads. Under such heads the necessary wall thickness, even with a moderate pipe diameter, becomes too great to permit of the use of riveted joints. Recent developments in electric welding and oxyacetylene welding have, however, rendered it possible to con struct suitable welded pipes and by their aid, and by the use of banded or solid drawn steel pipes in extreme cases, it has been found possible to harness the highest available heads.

The pipe-line for a water-power plant may be constructed of steel, reinforced concrete or wood. Steel is the most usual, riveted pipes being suitable for all but the highest heads. For heads up to about 200 ft., reinforced concrete pipes are suitable and have the advantage of not deteriorating appreciably with age. As compared with steel pipes the materials are more easily transported and the friction losses are less. Large pipes are moulded in site, and as the bulk of the material is usually ob tained locally, only the cement and reinforcement require to be transported for any distance. For small diameters, pre-moulded concrete pipes with loose-sleeve or spigot-and-faucet joints are often used.

For moderate heads, wooden pipes are extensively used in countries where suitable timber is cheaply available, and under favourable conditions have a useful life of at least 25 to 3o years. They are built up of wooden staves about 6 in. wide, shaped to the correct radius and joined end to end by thin metal plates driven into saw cuts on both the abutting ends, covering the joint. The staves are so arranged that the circumferential joints are not continuous. They are held together by circumferential steel bands which resist the bursting pressure, and whose diameter and spacing depend upon the pressure to be anticipated in each section of the pipe. The materials are easily transported and neither erection nor repair require any great degree of skill. If suitable timber is available the mill can be set up on the site and only the bands and shoes require transporting. As heads and diameters increase, the amount of steel necessary for the bands increases until it becomes comparable with that required for a steel pipe for the same duty.

In order that the walls of a wooden pipe should not decay it is essential that they should be kept saturated with moisture, and for this a certain minimum internal pressure is necessary. For this reason such a pipe is not suitable for heads less than about 20 ft., while the maximum suitable head is about 200 feet. Such pipes have been constructed in sizes up to about 18 ft. in diameter.

Generators.

Generators to be driven by hydraulic turbines range from the simple open-type machine, which is often ap plicable to small units, to constructions very similar to those of steam-turbine-driven alternators which are necessary for the largest high speed machines. On account of the very large outputs required in modern plants from a single unit running at the high speeds characteristic of the hydraulic turbine, the output per pole of the generator at normal frequencies is very large, and the cooling surfaces are small in comparison with the amount of heat to be dissipated. Special attention therefore needs to be paid to efficient ventilation of the rotor, which can only be ob tained by a carefully arranged system of forced draught. Me chanically the rotor must be designed to withstand the rotational forces accompanying the "runaway" speed of the turbine, which may be from three to four times the normal centrifugal forces.At the present time the energy is almost universally generated as alternating current on account of the simplicity and reliability obtained with a moderate generating pressure, which is readily transformed to the highest pressures which may be required for economical transmission. Of the two types of alternating current generator, the synchronous and the induction types, the latter has come largely into use of recent years on account of its robustness of construction and simplicity in operation.

Occasionally the advantages of high-tension direct current may outweigh the essential difficulties of its generation, in which case the Thury system may be used. In this system all generators and motors are in series, the current remains constant, and the voltage is varied according to the power demand. All generators are series wound, each having a governor which either varies the speed of the turbine, or, if the speed of the latter must be con stant, shifts the brush rockers. The maximum voltage per com mutator so far constructed is 5,000. By using a large number of generating units, connected in series, the system pressure may be as high as 8o,000 or i oo,000 volts. All generator frames are insulated from earth and it is usual to surround the machine with a wide insulated platform to ensure the safety of the operators.

Maintenance of constant speed is not of great importance, and the system therefore offers some advantages for such an installa tion, for example, as a tidal power scheme where the working head is continuously varying within wide limits.

Frequencies.

The question of the most desirable frequency of alternating current is simplified by the fact that in most coun tries two frequencies—a high and a low—have become recog nized as standard. In the U.S.A. and Canada, either 6o or 25 cycles per sec. is most commonly used for general utility pur poses and 25 cycles for railway power, although other frequencies (notably so cycles) are also used to a considerable extent. On the Continent 5o, 16i and 15 cycles are standard; in Great Britain and South America 5o and 25 cycles. As regards the number of phases there is little freedom of choice, the question being largely determined by the nature of the load. Single phase supply, though offering some advantage in simplicity of equip ment, involves increased losses in the generators and generally less reliable performance. This system is only used where ab solutely necessary, as for direct supply to alternating current railways using commutator motors. Of the polyphase systems, three-phase is preferable to two-phase for general power pur poses, since the plant is more fully standardized and therefore cheaper, while rotary converters are smaller, more efficient, and give better commutation on three-phase than on two-phase systems.

Voltage.

For distribution within a short radius of the power house the voltage of generation and transmission will be the same as that required for the supply to consumers ; but for transmission to greater distances, for which the voltage is stepped up, there is a wide choice of the voltage of generation. An unduly low voltage involves heavy and expensive bus-bars and switch-gear, and in large units presents difficulty in the construction of the stator windings of the generators. A very high voltage, on the other hand, requires a winding with many windings in series per slot, a greater thickness of insulation, and involves a generally reduced reliability. From the point of view of the construction of the generator it is desirable to have two conductors per slot, and the stator current should then vary from about 30o amperes in the smallest to I,000 amperes in the largest machines. It may therefore be shown that the most suitable voltage of generation, when not otherwise restricted for a three-phase machine, should vary approximately as follows : The power factor is here assumed to be o.8. For two-phase machines the pressure should be about o.9 times the above values. One of the most important modern developments in transmission has been in the direction of reducing the losses by increasing the voltage of the transmission lines.General Arrangement of Hydro-electric Stations.—The character of the development has a direct bearing on the general lay-out of the hydro-electric station. In a low head station, in corporated in a dam, the available space is limited by the width of the dam, and this in turn may be determined by the space required for the turbines. In consequence it is usual in a low head plant to locate the switch gear and transformers either on floors above the machine room, or, as is becoming more com mon, in a separate building on the river bank.

There is a growing tendency to install all transformers and high tension switch gear out of doors. Isolated examples of this already exist in Norway, France, Italy and Spain, and the practice is be coming standard in the United States. It has even been proposed to place the whole generating plant outside, merely providing a port able shelter for use during repair work, and such open-air stations will no doubt arrive in the near future.

Conditions vary so much that no general rule can be made that can govern or guide all hydro-electric station design. It is evident that the generating plant itself, water wheels or turbines and gen erators should be located where the greatest advantage can be taken of the available head of water. This condition, however, is not sufficient to guarantee the most economical power generation at the given site. The cost of construction of the plant as a whole must be estimated for different settings and arrangements, and the one chosen that will result in maximum overall economy. The other component parts of the complete station, the transformers, switch-gear, lightning arrestors and the transmission line terminals must be fitted into the available space in the best possible manner. We find these installed in the structure and on the top of the dam in one station and removed to a nearby hill in another if sufficient space is not available nearer the generating plant. Every power site presents a complete new set of problems.

Many medium head plants operate with vertical shaft units. For a low or medium head station, in which the variation in tail race level may be great, the vertical unit has great advantages in that it enables the generators to be placed above the flood level while leaving the turbines free to be arranged at any convenient and suitable height above the tail water.

For small units the horizontal shaft machine has some advan tages. Small electric generators are more economically built as horizontal shaft units since this allows of the simplest scheme of ventilation, and often enables a standard engine-type of machine to be used. In larger sizes again the horizontal type will often be preferable where, owing to governing difficulties, the shaft has to be provided with an additional flywheel. In high-head stations, if turbine equipment has been found suitable, the horizontal shaft machine is almost universally used, largely because of its accessibility.

For the highest heads water wheels such as the Pelton wheels are installed. These belong to the horizontal shaft type of ma chine. Pelton wheels have been built in units composed of two water wheels with the electric generator between them, so that only two bearings are required.

Automatic Generating Stations.

The automatic generating station is especially suited to systems where numerous small power falls are available. In such a case the expense of an oper ating staff at each would be prohibitive, but if each station can be made automatic, and all are linked into a common distribution sys tem, the labour cost is reduced to a minimum. The first of such stations was set in operation in 1917. This is on the system of the Iowa Railway and Light Co., where it operates in parallel with a steam plant situated about two miles away. The automatic station contains three Soo kw. generators driven by Francis turbines operating under a head of 10 feet. Normally the start ing and stopping of these sets is accomplished automatically through the medium of float switches actuated by the change in the level of water above the dam. Provision is also made for controlling these operations as well as the gate openings of the individual turbines by push buttons in the central power-house. Another system of automatic control is used in a station recently opened by the Adirondack Power and Light Co. This is capable of developing 7,300 kw. at 6,000 volts. The control is arranged by a switch in the high-tension line some miles away. To start the plant this transmission line switch is closed. This energizes a series of solenoids one of which is connected to the pilot valve of the governor and one to an interlock on the turbine gate; while two others release the water pressure brakes. The turbine gates are balanced at about 3o% gate opening, and so automatically open when released. The speed of the unit then increases until at about 95% of synchronous speed a relay closes the circuit breaker connecting the generating unit to the transmission line. The unit then comes into synchronism and the field switch closes. The unit is now excited and under governor control and takes the load corresponding to the governor setting. There are a num ber of protective relays and devices, and any kind of trouble causes the unit to shut down.The development of automatic generating stations is proceed ing steadily and this method of operation promises to do much to render it economically possible to utilize many low-head river sites which have hitherto been neglected.

Combined Operation of Hydraulic and Steam Plants.— Except where a large amount of storage is provided the variability of river flow makes it impossible to utilize more than a fraction of the total available energy unless generating machinery is installed which will have to be idle during the greater portion of the year. Broadly speaking it is found that the most economical results are obtained when the capacity of the turbines is such as will enable them to be run at full load for about six months in the year.

By operating a steam plant in conjunction with the hydraulic installation, it becomes economically possible to increase the capacity of the hydraulic plant, the defect of its output at times of less than normal flow being made good by the steam installa tion. The latter also serves as a stand-by in case of a breakdown of the hydraulic plant. (See SUPER-POWER.) Most large hydro-electric power systems in 1928 included one or more steam plants as part of the system. The best method of operation of such a combination depends upon the type of load, the storage capacity of the hydraulic system, etc., and can only be determined by a consideration of the special circumstances of the individual plant. In general, since for maximum economy a steam plant requires to operate at something approaching its normal capacity, at times of low water the steam plant operates con tinuously, carrying the base of the load, while the peak of the load is taken by the hydraulic plant. On the other hand, in a sys tem having a very long transmission line it has been found more economical to let the hydraulic plant carry the base of the load, working at a reasonably high load factor, and to carry the peak of the load by the steam plant. In this method of operation the cost of the transmission line is less than if the reverse method were adopted, and the saving in this respect may more than counterbalance the extra expenditure due to the less economical operation of the steam plant.

While in the early days of hydro-electric developments criti cisms were justly leveled at the inaesthetic nature of such develop ments, much attention has been paid of recent years, more espe cially in Switzerland and in Italy, to the architectural possibilities of the hydroelectric plant. These plants stand at the foot of the mountains overlooking the plains or in a setting of rock at the mouth of a narrow gorge ; nearly always are they located where the architect should be impelled to add beauty to usefulness even without the fear or the pressure of criticism. (See also TURBINE,