Printing Machinery and Calenders

PRINTING MACHINERY AND CALENDERS A number of industrial operations, of which rotary printing presses form a typical example, involve an accurate regulation of the working speed over a very wide range. Methods of control employing field regulation, resistance in series with the armature, and diverting resistance have already been described ; but for the of functions to be dealt with in this section, additional means are frequently essential.

The inadequacy of series and diverter resistances is chiefly due to their destroying the constant speed characteristic of the shunt motor, and causing serious variability with loading conditions. Field regulation is however available as far as it goes ; while the Ward-Leonard system of control is an ideal, though frequently a too expensive, method. Multiple-voltage control is also of assistance. But for many purposes, especially in connection with printing, calendering and paper making, special methods are necessary. In considering these, attention should be particu larly directed to great importance of securing a definite and steady slow speed for threading-in ; for a sudden spurt, immediately the initial static friction is overcome, must be avoided.

For the least exacting requirements, the "inching" starter shown in fig. 2 may be serviceable, since it permits the motor to be inched or "jogged" at slow speed as a preparation to the main run.

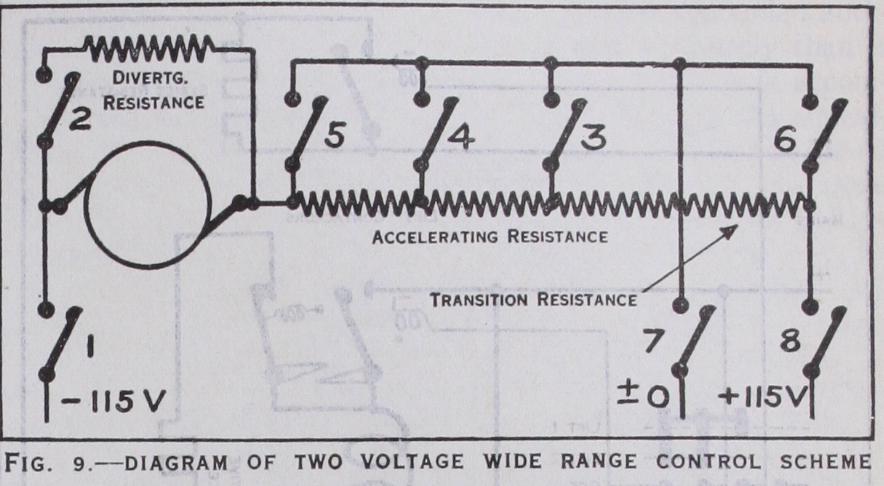

More delicate operation is given by a combination of field, series and diverting resistances with two-voltage control; and a scheme for effecting the change-over of voltage together with the other methods is shown in fig. 9. The supply is here assumed to be derived from an ordinary three-wire system at, say, 115/o/-115 volts. There are eight contactors in all, and the scheme of operation would be as follows: Close 1, 2 and 7- thread-in speed; open 2-slow speed; close 3, 4 and 5 in suc cession—acceleration to half-speed; close 8, then open 3, 4, 5 and 7--transition to full voltage; close 6, 3, 4 and 5 in succession— acceleration to full speed; open i and 8, and close 2-stop. This scheme would preferably be combined with field regulation; while all the methods of control need not be included.

Of the special means employed for this class of work, the Holmes-Clatworthy two-motor system will be described for the drive of printing presses, and the Harland interlock scheme for paper machines. The former was developed in 1898, and involves the use of a small worm-geared motor for producing the creeping speeds, and the smooth transference of the drive to a large direct coupled motor when a given speed has been reached. A mag netically-operated clutch positioned between the small and large machines enables the change-over to be automatic and without shock.

A self-contained control pillar is employed embodying con tactors and relays, and a motor-driven distributing switch. The latter cuts resistance into and out of the two motor circuits as required, and opens and closes the circuits for the machines themselves, so that the speed is smoothly and gradually increased as the servo-motor rotates in one direction, and similarly re duced when its rotation is reversed. The gear is operated from any point round the printing press by means of any number of push-button stations. Pressing the "Up" button accelerates the speed while it is held down, and the reverse is true of the "Down" button. The "Inch" unit institutes a very slow movement which ceases as soon as the button is released ; while the "Lock" button prevents the machine from being started until its own "Free" button is pressed. By all these means the paper is safe-guarded from being torn, and the operators from suffering injury.

The distinguishing feature in connection with paper making is the necessity for maintaining exactly the same relative speeds between all the numerous rollers involved in the process; for great trouble is caused if the paper is either torn or becomes slack. It is nowadays customary to drive the complete machine by a number of electric motors, all of which are supplied with power by a motor-generator set. The speed of the whole process can thus be increased or diminished as required by the field regulation of the generator. The requirement is then to co-ordinate the speeds of the various "section" motors so that none of them can deviate by a fraction of 1% from the predetermined value rela tively to the speeds of the other machines.

This co-ordination of speeds is quite simply accomplished in the Harland equipment. A master shaft runs transversely to all the motor shafts, and is driven either by a special motor or by that of the "drier" section. One-half of a differential gear, de signed on exactly the same principle as that used in a motor car back axle, is spur-geared to this shaft, while the other half is belted to the shaft of the section motor. While the two halves run at the same speed but in opposite directions, the planet wheels and frame do not move; but when movement does occur, resistance is cut into or out of the field circuit, a rheostat having about ioo steps being incorporated in the "differential" case. The most delicate regulation is thereby obtained.