Escalators

ESCALATORS. An escalator is a form of moving staircase in which motion in the plane of ascent is imparted to the stairs by mechanical means. Therefore a person standing on a step will be carried up or down according to the direction of motion. The early moving staircases were, in effect, inclined link belts forming inclined platforms without steps. As these are uncom fortable at any angle giving a reasonably high rate of ascent, mov ing staircases were later developed with steps, firstly by super imposing small articulated steps on the belts, and later by con structing unit steps running on tracks and attached to a chain ; it was to these machines that the name "escalator" was given.

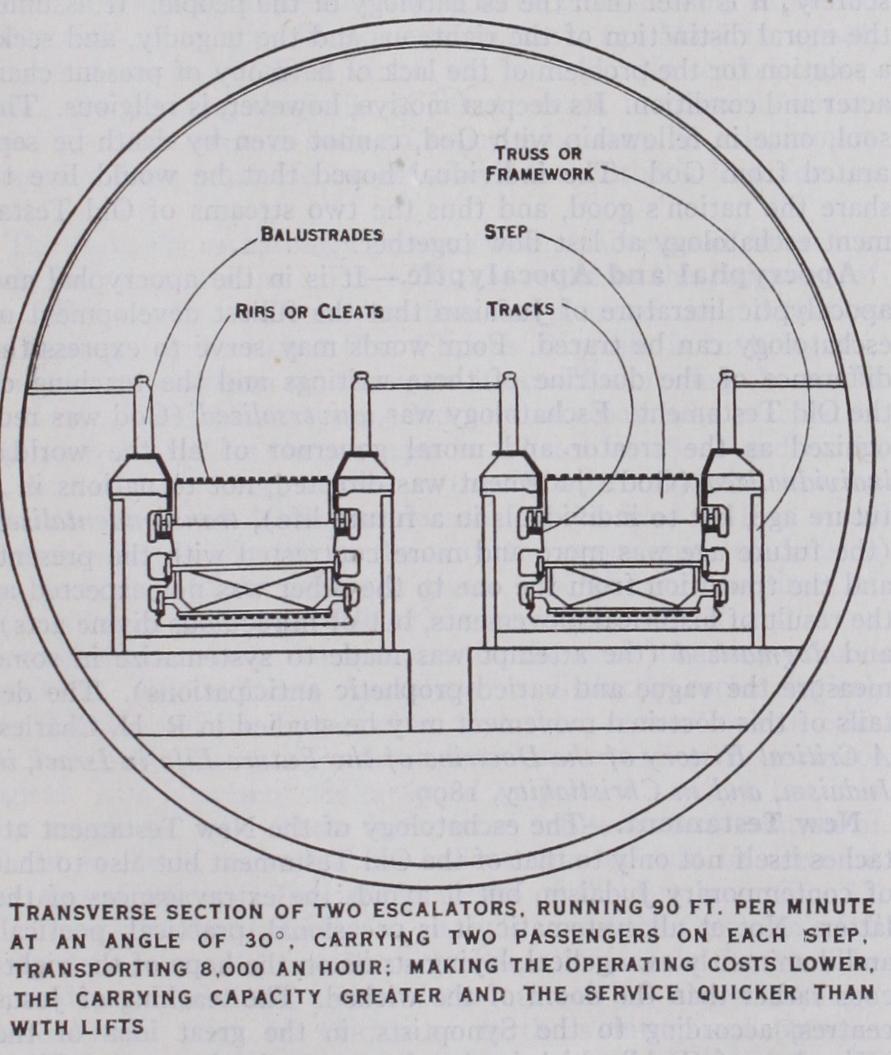

Four tracks are used, two being on each side of the step, and one of each pair for the back and the front. At the land ings it is required that the steps form a level platform. This is done by arranging the supporting tracks so that they curve from the slope to the level in such a way that the horizontal distances between the tracks supporting the front and back of the step are always the same and equal to the distance between the wheels of the step running on these tracks; thus the top surface of each step is kept horizontal. In the early step machines the axes of wheels of each step lie in a horizontal plane and in later machines in an inclined plane. The stairway runs between balustrades of wood or metal construction of form and shape varying accord ing to local conditions. This balustrading commonly carries a flexible moving handrail, to assist the passenger in the ascent or descent. The tracks for the steps are carried in a truss or frame work. The steps are attached to either one central or two side chains driven by sprocket wheels.

The earlier type step machines have a central chain driven at a point a little way down the slope and are provided with semi circular tracks to transfer the chain and steps from the "go" to the "return" side. Some of the dependent weight of the chain and steps is relieved from the driving sprocket by introducing one or more sprockets, free to move and loaded by springs in the direc tion of the centre line of the machine and engaging the "go" and "return" sides of the chain, these sprockets being situated below the main driving sprocket and not supplied with any ex ternal power. In order to keep the chain and steps in contact with the curved track at the landing curves, the semi-circular tracks are loaded with weights. On the later machines the steps are arranged between two chains passing over sprockets at the ends of the machine. The upper sprocket runs in fixed bearings and is driven, while ,the lower runs free and a tension is kept on the main chains by a counterweight pulling the lower sprocket outwards, the bearings being movable. Safety devices are pro vided to deal with any irregular operation or breakage, such as broken chains, overspeed or reversal of the machine.

It is necessary to ensure that the user is transferred safely from the moving steps to the fixed landing. This is done on a step type machine with flat tread steps by arranging the steps to run flush with the landings and providing a diagonal barrier across the line of motion, thus ensuring that any person not stepping off sideways on to the landing is pushed off by contact with the barrier. An alternative construction which is more commonly used is to arrange ribs or cleats on the step tread at short distances apart and running from back to front of the steps. At the landings a metal comb is arranged with teeth projecting at a slight angle downwards towards the steps. The cleats on the steps move horizontally through the spaces between the teeth of the comb, and, since the plane of the top of the comb intersects the plane of the top of the cleats, the feet of any person not stepping off at the landing are slid gently up on to the stationary comb which joins the landing floor. This latter construction was also used on the earlier ramp type machines.

The usual linear speed, or speed of the steps up or down the incline for escalators, is 9o--I oof t. per min. corresponding, at the usual 30° angle of ascent, to a vertical speed of per min., this representing a practicable operating speed both from the engineering and the passenger points of view. The limit of speed must depend on the landing arrangements and the necessity of catering for passengers of all ages and degrees of activity.

The escalator has an outstanding advantage over lifts or ele vators in its continuity of action, and where vertical travel is asso ciated with a displacement of the upper landing in relation to the lower, an escalator has the advantage of providing simultane ous movement in two dimensions; also the operating costs are lower. One escalator (one pair one up and one down) is equiva lent in carrying capacity to several lifts, the equivalent number of lifts depending on size and speed.

The escalator has not yet been constructed for more than 6oft. vertical rise and this probably represents a practical operating limit. The lift is therefore a necessity for high rise services, unless two flights of escalators are used, with the consequent long time involved in the journey. Escalators are usually made of three sizes; i.e., 2 f t., 3 f t. and 4ft., between balustrades. An escalator at any angle of 30° with the horizontal, running at Soft. per min., carrying two passengers stationary on each step (4ft. wide), will transport 8,100 passengers per hour. If the passengers walk at the same time the capacity may be increased by 40%. Escalators are now in general use throughout the world in subways and elevated railways, industrial and factory buildings, restaurants, theatres and department stores. (W. S. G.-B.)