Fans

FANS are devices for setting air or gases in motion. Mechani cal contrivances for this purpose are a necessity in a great number of manufacturing processes. For ventilating, warming or cooling buildings, ships and mines, air must also be propelled large volumes. In cases where a blower or blowing engine (q.v.) is not required to give pressures above the range of a fan, the latter is employed, reaching in capacity from the tiny table fans to the huge mine fans requiring over one thousand horse-power to drive. The hand fans and the punkahs do not actually bring fresh volumes of air but only keep in motion the air in the neighbourhood. A rotary fan transfers air or gases completely from one location to another. It may be a blowing fan or an exhausting one, according to the purpose desired, and it may move solid matter along with the air, as dust, wood and other shavings, and powders and woolly substances.

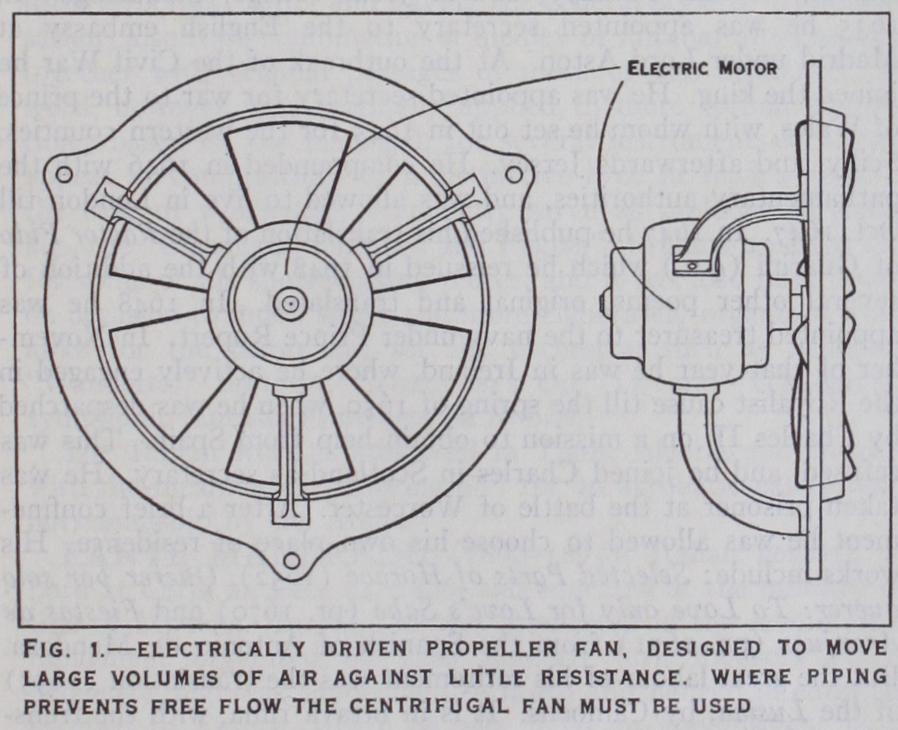

Fans are divisible into two classes, the screw or propeller type and the centrifugal or impeller type. The former acts on the principle of the inclined plane, the latter by centrifugal force created in the air which revolves with the impeller wheel. Pro peller fans will move large volumes of air, but they are mostly used with "free air," that is, little or no resistance must be caused by piping, flues, etc., or the efficiency of the fan rapidly drops.

Hence it is often called a volume fan. The simplest design is that of the ceiling fan, depending from a vertical hanger, carrying at the bottom end the electric motor and the fan blades, two, three or four in number. The motor may be pivoted so as to vary the direction of the flow of air. Desk or bracket fans are on a pillar, and the blades are protected with a wire guard ; automatic oscilla tion is often included to increase the area of influence. Types for affixing to a wall or window or partition or for placing in a duct comprise a frame with lugs for the attaching screws, and bearings for the spindle, which is belt driven or by direct motor, fig. 1.

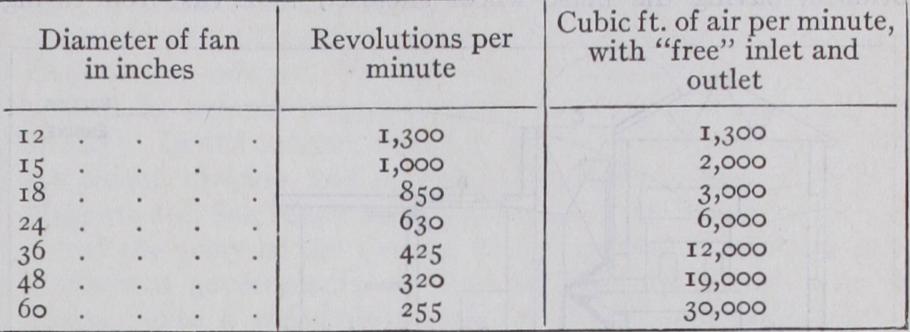

Protection against weather is frequently given by means of a hood, and against back draught when the fan is stopped by an automatic shutter; this has two light doors which close by gravity but fly open easily when the fan commences to run. The quantity of air moved in a given time depends on the speed, but the follow ing table affords an idea of output with Sturtevant fans : The blades in fig. 1 are of open sort, while another kind, the box blade, has the tips encircled by a binding ring, affording greater rigidity, and permitting of higher speeds. Very large propeller fans are built up to about 1 o ft. diameter, one of this size giving 246,000 cubic ft. at 25o revolutions per minute, and consuming 42 h.p. The small pressures produced by fans are measured against a column of water in a water-gauge, and stated in inches and parts of the inch.

The centrifugal fan takes in air at the eye or side opening of the casing, and the numerous blades of the impeller seize it and throw it off tangentially from their tips. The casing is built of such shape that its opening provides the tan gential discharge, fig. 2, which may be arranged horizontally, or upwards, downwards or at an angle. Steel plate is employed to make the casing, but in the large-mine fans there is a good deal of ma s o n r y enclosure. Shapes of blades differ consider ably ; in some fans they are relatively few in number and of large area, in others numerous and narrow. The Sirocco fan made by Davidson & Co. Ltd. of Belfast in the eastern hemisphere and by the American Fan Blower Corporation in the western hemisphere led a practice in the latter direction, the wheel possessing a lot of narrow, long blades (fig. 3) with their outer edges curved forward in the direction of rotation. The eye or intake is of equal diameter to the wheel. When the fan runs, centrifugal force is cre ated upon the body of air within the wheel. This causes a partial vacuum in the central space between the blades, to be imme diately filled by air entering the inlet. As the air moves outwards over the blades its speed in creases. The greater the wheel speed the higher the velocity. Double-inlet fans comprise two - - - --. - -- .-- wheels on the same shaft, each drawing from the side ; large duty can be obtained in this way in limited space. Many large fans are driven at each end of the shaft, the steam engine being in duplicate for this. The surface fans of mines are capable of being used either to exhaust air from the mine, or to blow fresh air down. This is done by means of an arrangement of doors and dampers in the fan. Fig. 4 illus trates the arrangement as applied to a steam-driven outfit by The Waddle Patent Fan and Engineering Co. Ltd., Llanelly (Wales).

The door A closes the by-pass drift when the fan is exhausting.

When it is required to blow fresh air down the upcast pit, A is swung on its hinges, thus shutting off the main drift from the fan inlet. Then door B is lifted to admit fresh air to the fan, and flap-doors C dropped shut, the fresh air being consequently dis charged along the by-pass drift (uncovered by door A) and along the main drift to the upcast shaft. The ordinary air-lock doors for getting into the fan drift are at D, and serve as an additional inlet for fresh air.

For supplying the blast to cupolas, forge fires, furnaces and other services requiring high pressures a narrow kind of fan is utilized, having the blast wheel enclosed in a cast-iron casing.

Another special construction is the dust fan wheel, which is built very strongly to withstand the impact of materials sucked in (such as chips and small pieces of wood from the machines) and the flow of air is such that the blades do not become choked with the material.

Applications of Fans.Air supply for ventilating purposes is necessary in cases where nat ural ventilation does not suffice, not only for people but for the ventilation of various kinds of rooms carrying on processes, or cargo holds, engine-rooms, fig. 5, ' as well as individual machines, notably electric generators (see COOLING SYSTEMS). A big liner will have more than one hundred fans on board. For warming the air in heating systems steam or direct-fired heaters are installed, the former utilizing live or exhaust steam, the latter wood, coal, coke or oil fuel. Air-washers are also used in conjunction with fans when it is essential to avoid the carrying in of dirt into a building or amongst machines, or goods in process of manufacture; sprays of water break up the air and cause the dust and grit to fall by gravity into a tank. The cooling of the air is obviously beneficial, for certain purposes. Warm air for drying purposes is applied either in rooms, cabinets or tunnels in which the goods to be dried are placed. Substances include various foodstuffs, as bacon, tea, fruit, vegetables, grain, milk, sweetmeats and so on, also glass, starch, rubber, leather, paint, various paper goods, chemicals, and some things in course of manufacture, as tins and boxes.

Timber seasoning is effected by a fan sending warm air through the kilns; a certain degree of humidity has to be maintained, either by mixing steam with the air, or re-circulating part of the air which has already extracted moisture from the timber. Re cording instruments have to be installed to take readings of temperature and humidity, so that control may be exercised.

In addition to the supply of air to forges, cupolas and furnaces, fans are also employed to create draught for steam-boiler fur naces, giving increased steaming power, and economy of fuel. Low-grade fuels can be burned satisfactorily, because of the extra volume of air forced through the fire, and there is incidentally reduction of smoke, while chimney height may be considerably less than for natural draught. Another type of pressure applica tion is that of pneumatic elevating and conveying, transporting through tubing such light materials as sawdust, wool, bark, chaff, cotton, cork, etc., and carriers for messages, coins, etc.

Great value is obtained from fans in industries which create dust, grit, cuttings, fibres, steam and fumes, the extraction and complete removal of these being effected through ducts. Many reasons may be mentioned why this is necessary, some having to do with the workers' health, others non-interference with the machines or processes by the waste products, and in many cases safety from fire or explosion. The general principle is that of placing a hood about the spot where the products come off, the fan suction whisking them away instantaneously. But for this some machines would be unwork able ; some wood-working ma chines would bury themselves in their cuttings in a few minutes, brushing away being impracti cable as well as dangerous. A big sheet-metal casing termed cyclone separator receives the refuse and in its conical body a whirling motion causes the refuse to fall to the bottom and thence to boil ers to act as fuel. Refuse which reaches the floor of a factory is brushed along to a sweep-up, fig, 6 (Sturtevant), which sucks everything away similarly to the hoods on the machines. Industries requiring dust removal plants include principally wood-working, metal-grinding, polishing, clean ing by tumbling barrel, sandblasting, leather and textile processes, brush factories, paint works, paper mills, potteries, linoleum works, granaries, cement works, collieries and quarries. Prevention of atmospheric pollution is another field for the fan collection system, dust particles which are carried up the chimney in power plants, especially when cheap and small fuels are burned. The dust nuisance has often compelled power stations to buy more expen sive fuel on this account. An extreme case is quoted at a Scotch colliery, where coal-dust and slack is fed to the boilers, being a fine and dirty mixture. When a Davidson collector was installed no less than 45o lb. of dust per hour were trapped, from two boilers, using 5,500 lb. of fuel per hour. (F. H.)