Joinery

joint, tenon, boards, called, tenons, glued, material, width, square and framing

The kinds of wood commonly employed in joinery are the different species of North European and North American pine, oak, teak and mahogany (see TIMBER). The greater part of English joiners' work is executed in the northern pine exported from the Baltic countries. Hence the joiner obtains the planks, deals, battens and strips from which he shapes his work. The timber reaches the workman from the sawmills in a size con venient for the use he intends, considerable time and labour being saved in this way.

A log of timber sawn to a square section is termed a balk. In section it may range from I to II ft. square. Planks are formed by sawing the balk into sections from I I to 18 in. wide and 3 to 6 in. thick, and the term deal is applied to sawn stuff 9 in. wide and 2 to 41 in. thick. Battens are boards running not more than 3 in. thick and 4 to 7 in. wide. A strip is not thicker than I2 in., the width being about 4 in.

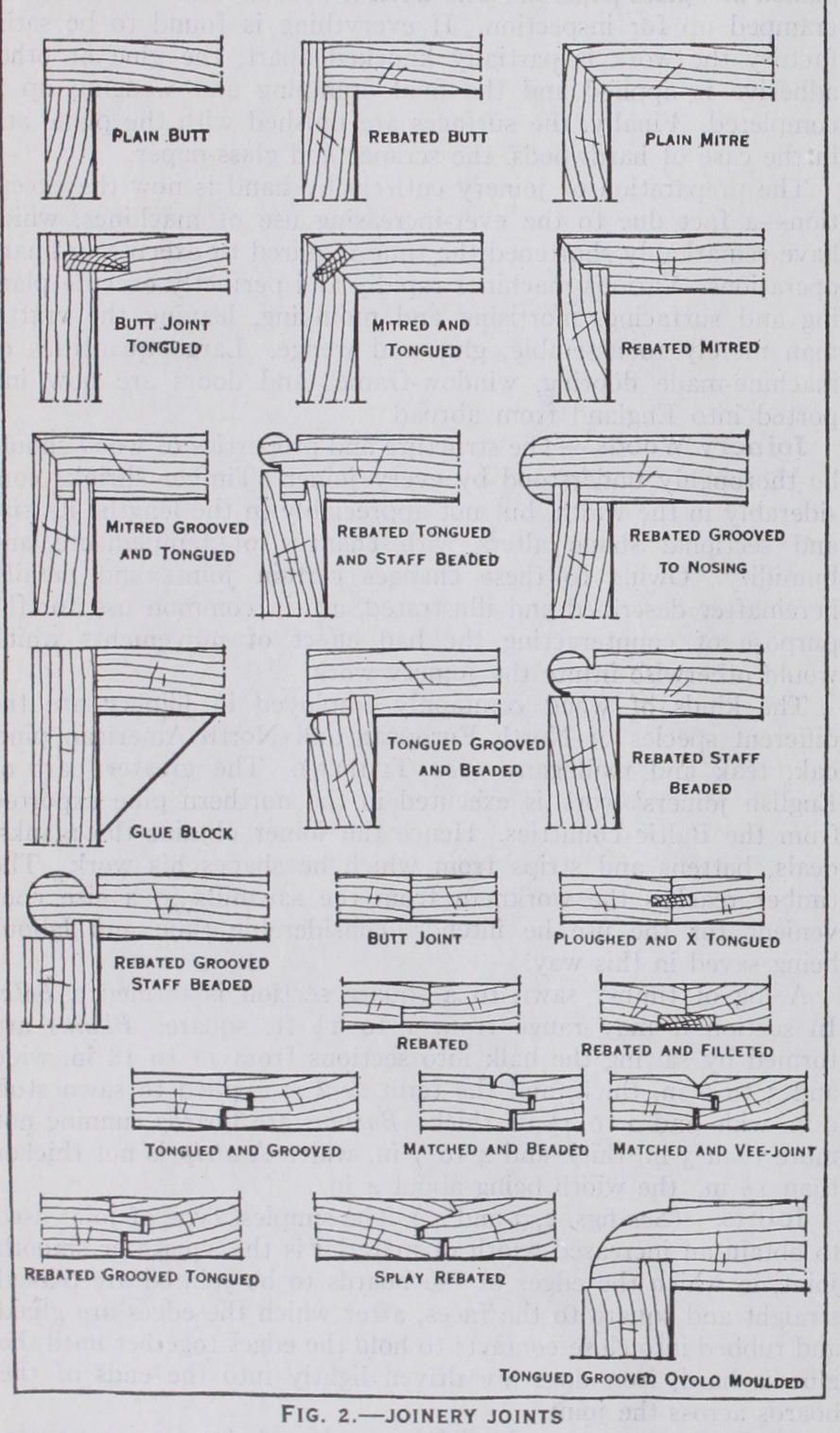

Joints.—(See figs. 2, 3 and 4.) The simplest type of joint used to obtain an increased width of material is the square or smooth joint, in which the edges of the boards to be jointed are planed straight and square to the faces, after which the edges are glued and rubbed into close contact ; to hold the edges together until the glue is hard, iron dogs are driven lightly into the ends of the boards across the joint.

A joint in general use for joining up boards for fascias, panels, linings, window-boards, and other work of a like nature is formed in a similar manner to the above, but with a cross-grained tongue inserted, thereby greatly strengthening the work at an otherwise naturally weak point. This is termed a cross-tongued and glued joint. The dowelled joint is a square glued joint strengthened with hard wood or iron dowels inserted in the edge of each board to a depth of about a in. and placed about 18 in. apart. The matched joint is shown in two forms, beaded and V jointed. Matched boarding is frequently used as a less expensive substitute for panelled framing. Although of course in appearance it cannot compare with the latter, it has a somewhat ornamental appearance, and the moulded joints allow shrinkage to take place without detriment to the appearance of the work. The rebated joint is used in the meeting styles of casements and folding doors, and it is useful in excluding draughts and preventing observation through the joint.

Angle Joints.—For joining the edges of boards and framing to gether so as to form an angle between the faces of the material the following are the principal joints used : the plain mitre joint, the tongued mitre joint, the rebated and mitred joint, the tongued grooved and moulded joint, and the rebated grooved and moulded joint. Their chief uses are at the external angles between dado and other vertical framing, and at the angles between beam and pipe casings.

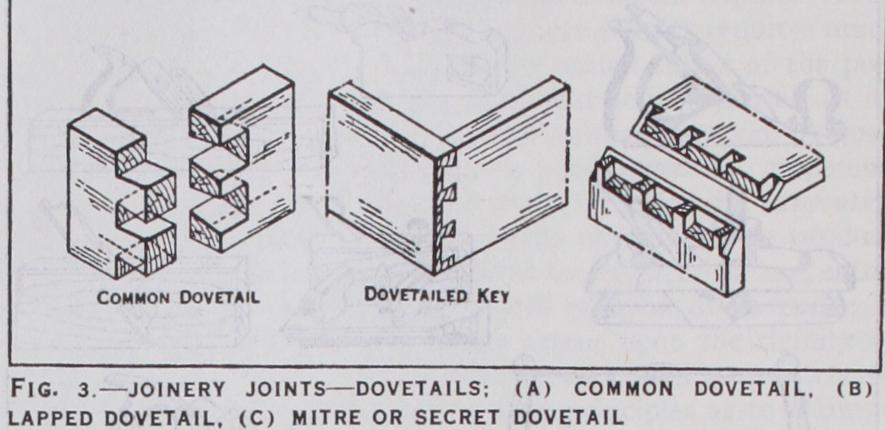

The dovetail is a most important joint ; its most usual forms are illustrated in fig. 3. The mitre dovetail is used only in the best work. It will be seen that the dovetail is a tenon, shaped as a wedge, and it is this distinguishing feature which, if closely fitted, gives it great strength irrespective of glue or screws. It is invalu able in framing together joiners' fittings; its use in drawers espe cially provides a good example of its purpose and structure.

Housed Joints.—This term is applied when the face of a board is grooved or trenched to receive the end of a second board; when the sides of the groove are square it is a plain housing, when the sides are bevelled it is a dovetailed housing. When the groove is

stopped a short distance from the edge of the material it is called a stopped housing. The housed joint is used in fixing shelves, at the head and sill of a cased window frame, between the steps and strings of stairs, and for many other similar purposes.

Mortise and Tenon Joints.—When the end of a wooden member is cut to fit into a rectangular hole in a second member, the joint is called a mortise and tenon joint; the hole being the mortise and the fitted end, the tenon.

This is probably the most generally used of all joinery joints since practically all framing is held together by this method.

The rules relating to this joint are :—(i.) the thickness of the tenon should be about one-third of the thickness of the material to be jointed; (ii.) the width of the tenon should not exceed five times its thickness. When the width of a tenon is cut away to make it accord with "rule ii." it is called a haunched tenon; the position from which the part of the tenon has been removed is called the haunch. A third rule is :—the sum of the widths of the haunches should not exceed the sum of the widths of the tenons.

The second and third rules are of importance only when the tenon is fixed by wedges ; when the tenon is pinned its width is not so important since undue shrinkage would not affect the pin whereas it would tend to loosen the wedges.

The number and positions of tenons on the same end of one piece of material are referred to as follows :—one tenon is a single tenon; two tenons in the same plane are called "a pair of single tenons"; two tenons side by side are called a "double tenon"; four tenons, two in each of two planes are called a "pair of double tenons." When a tenon passes only partially through the material it is called a "stub tenon." Other forms of tenon are called "fox wedged," "tusk," and "dovetailed and keyed tenon." Warping in Wide tendency to warp, twist and split, which boards of great width, or several boards glued together edge to edge, naturally possess, must be provided against in the construction. On the other hand, swelling and shrinking due to changes in the humidity of the atmosphere must not be checked, or the result will be disastrous. To effect this end various simple de vices are available. The direction of the annular rings in alternate boards may be reversed, and when the boards have been carefully jointed with tongues or dowels and glued up, a hard-wood tapering key, dovetail in section, may be sunk into a wide dovetail at the back (fig. 4). It must be accurately fitted and driven tightly home, but not glued. Battens of hard wood may be used for the same purpose, fixed either with hard wood buttons or by means of brass slots and screws, the slots allowing for any slight movement that may take place. With boards of a substantial thickness light iron rods may be used, holes being bored through the boards edgewise, the edges glued up and the rods passed through. This method is very effective and neat in appearance, and is specially suitable when a smooth surface is desired on both sides of the work.