Paperhangers Tools and

roller, fig, iron, bolt, handle, wood and brass

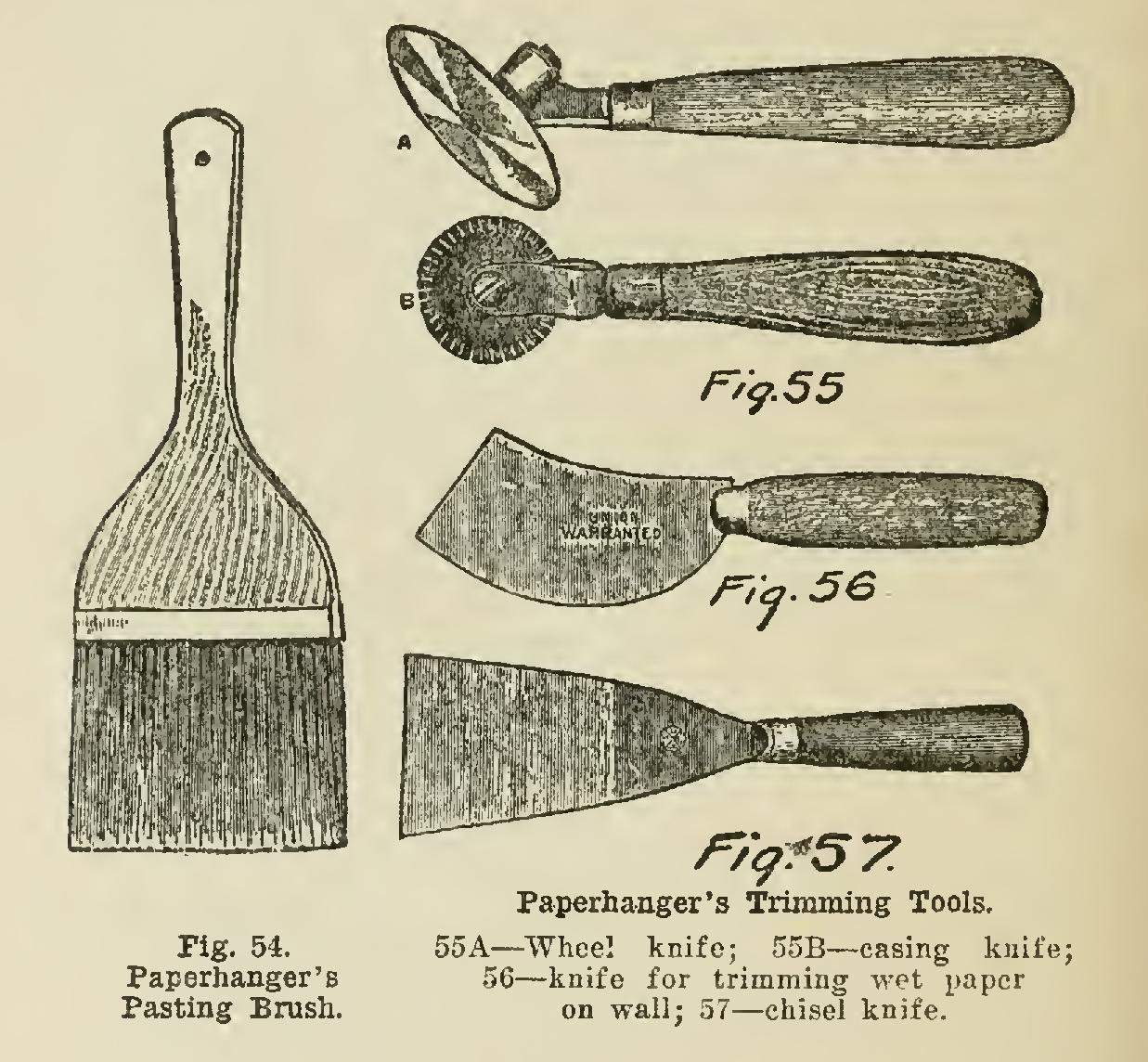

PAPERHANGERS' TOOLS AND The ordinary form of pasting brush is shown in Fig. 54. This is useful for distempering; also a half-worn "paddle" brush makes a good brush for paste, as, being wide, the paste can be spread quickly—a great advantage when us ing cheap papers, which will not stand much soaking.

Scissors

are required in two sizes, one pair 12 inches long, including handles—for trimming; and another pair-9 or 10 inches long—for cut ting wet paper. Scissors, even though wielded with great dexterity, are necessarily slow in ac tion and unreliable as to straightness of cut. It has been long recognized that for such work scissors can hardly be classed as "instruments of precision," and there have been many at tempts to supersede them, and many trimming machines have been introduced.

American paperhangers employ methods and tools which are distinctive and ahead of those in other countries.

For use with a straight-edge, the American paperhanger has the wheel-knife with 2-in. blade (A, Fig. 55) ; for trimming wet paper on the wall, he has the casing knife with serrated blade (B, Fig. 55). The knife shown in Fig. 56 is used for the same purpose as the wheel-knife (A, Fig. 55).

The paperhanger will have many uses for the chisel knife illustrated in Fig. 57.

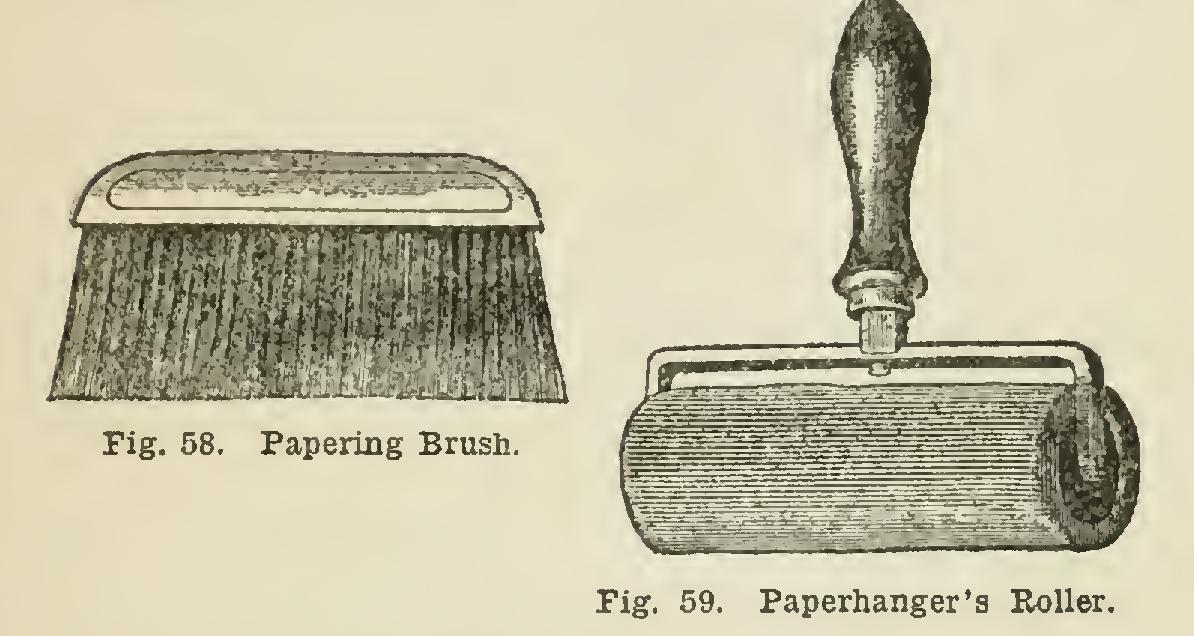

Brushes for lightly pressing the pasted paper to walls are of the kind shown in Fig. 58. The back is shaped to resemble that of a spoke-brush, and is long and thin so that the hand can grasp it comfortably.

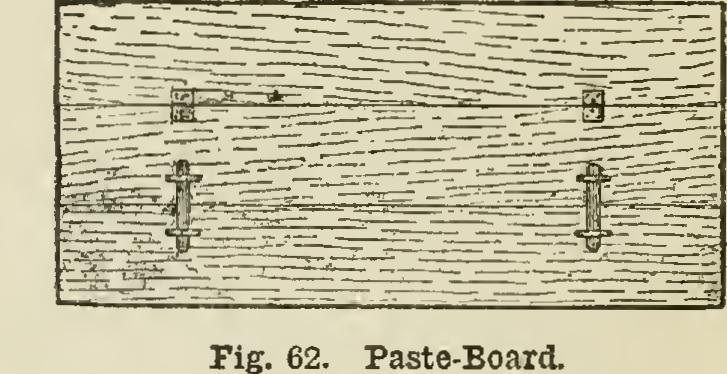

A paperhanger's roller (Fig. 59) for use in stead of a brush on the better class of papers, is obtainable at the tool dealers. One can be made easily as follows: A piece of iron 1/2 in. by in. by 1 in. long is marked in the center, and at in. from each end, with a center-punch, and the ends turned up like a double L. Three holes are bored, one in the center to take a bolt, and one % in. from each end, to take a No. 7 screw (see Fig. 59). A handle 5 inches long is turned and fitted with a brass ring, while a bolt with its head filed off is inserted, plain end inside, leaving the screw exposed 1/2 in. or in., this screw being passed through the center hole of the iron and screwed up. A pin passed

through the handle into a notch in the bolt, or a hole bored right through with a small drill, would prevent the bolt drawing out. A rod of wood, turned 1 in. in diameter (a piece of broom handle would do), and in. shorter than the dis tance between the horns of the iron, receives in the center of each end the screws that pass through the iron. Cover the wood with six or eight thicknesses of felt, baize, or soft cloth by tacking one end of a strip of the same width as the roller and winding round tight until there is about in. distance between the nut of the bolt and the cloth. Sew down firmly and iron the seam, and a good soft tool is the result.

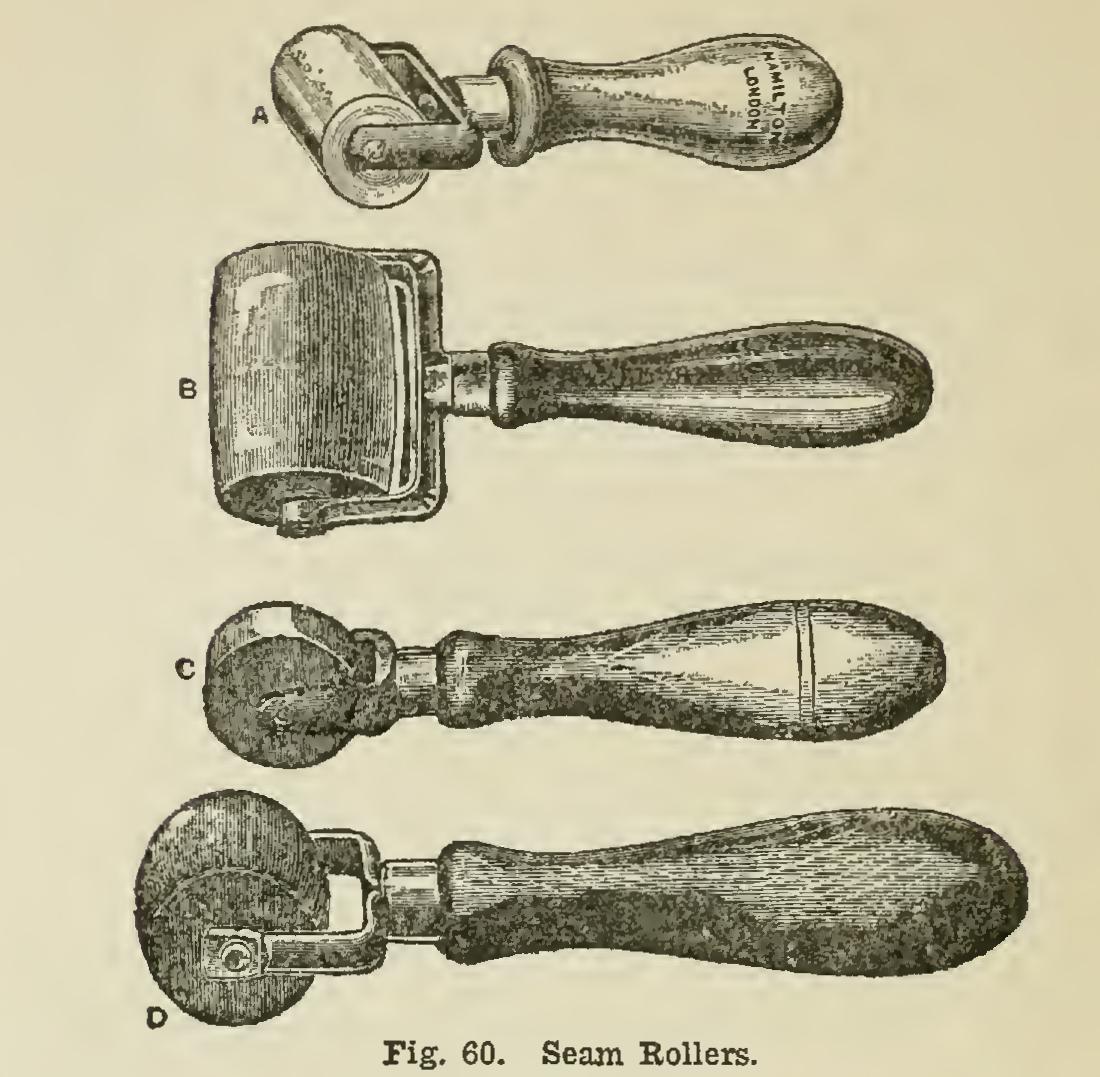

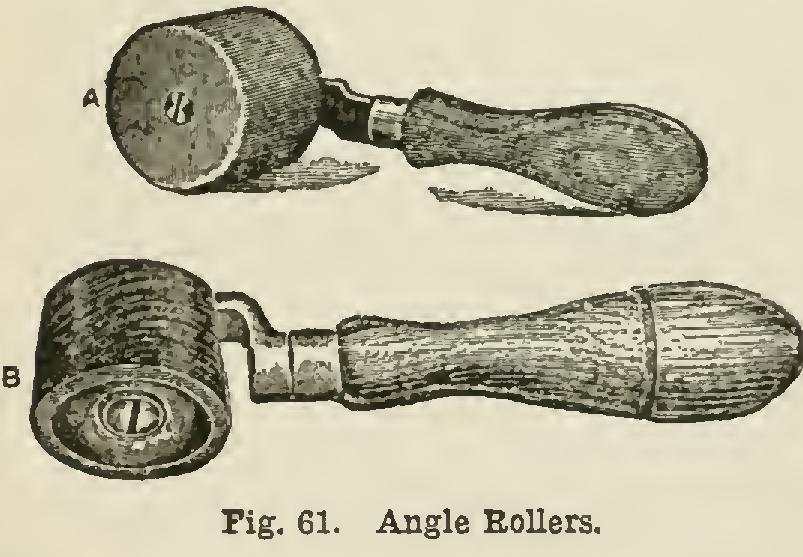

The seam roller may be a solid brass roller, obtainable in four widths, in., 2 in., 21/2 in., and 3 in. A good substitute is a wheel-easter mounted in a brad-awl handle. A wheel off a roller skate is another substitute. Fig. 60 shows four kinds of seam roller: A, solid brass; B, lig num vita; C, zylonite; and D, maple. The angle roller may be improvised from one of the above, or a special boxwood roller may be obtained.

For some purposes, as will be noted later, a china wheel is much to be preferred to a metal one. Fig. 61 (A) shows a boxwood angle roller, and (B) a lignum vita roller.

A seam roller could be made in much the same way as described above; instead of using a wood roller, an ordinary 1-inch gas socket, plugged with wood and mounted with only two thicknesses of felt, would do better.

Other requisites are—a four fold 2-foot rule, a steel straight-edge, a plumb-line, a spirit-level, a small hammer, and a screwdriver and pinchers for removing nails, etc., from old walls. The straight-edge (3 ft. long) is made of hardwood, with a keen beveled edge; or, better still, of met al (brass or steel). This tool will save much time when the paperhanger knows how to use it properly. If it has inches marked on it like a glazier's T-square it will save using the rule for measuring, and will be much handier. A bibbed apron with large pockets for the small tools should be worn by the paperhanger.