A Folding Porch Chair

pieces, inches, inch, one-quarter, lines, piece, cut and rods

For the part which supports the back (Fig.

31, upper part), there will be needed two pieces squared to seven-eighths by two by twenty-two inches. The ends are to be beveled one-quarter of an inch.

There will be a one-inch hole centered at one and one-quarter inches from one end; a one quarter-inch hole at one and one-quarter inches from the other end; also a one-quarter-inch hole measured seven and five-eighths inches from the same end. The pieces should be paired, the lines squared across, and the middles gauged as with the other pairs previously described.

The arms (Fig. 31, lower part), should be squared to seven-eighths by two by eighteen and one-half inches. One end only of each piece is beveled to one-quarter of an inch.

On the unbeveled end is to be cut a slope run ning from the middle of the end, or one inch from either edge, back to a point measured from this same end three inches along an edge.

Two holes are needed in each of these pieces. Pair them, and lay off in the usual way for holes of one-quarter-inch diameter, one inch from the beveled ends. Gauge for the middle as usual. The other holes would best be laid off and bored after the parts are assembled, as this will permit adjusting the parts as desired.

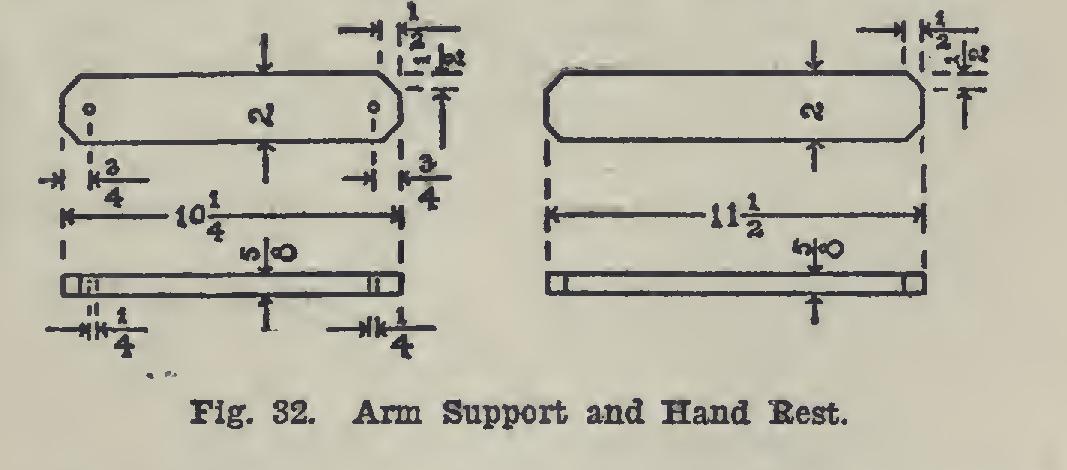

The two pieces which support the arms (Fig. 32, left) are to be squared to five-eighths by two inches by ten and one-fourth inches.

Cut the corners, not bevel, one-half an inch each way; that is, measure from the corner along the edge and down the end.

Pair the two pieces, and lay off for holes three-quarters of an inch from each end and in the middle. It will probably be better to lay off and bore these holes before the corners are cut off. They are to be one-quarter inch in diameter.

In laying off all these pairs, do not make the mistake of squaring the lines across the two pieces with the edges together and the broad surfaces up; but place the broad surfaces to gether and the edges up, carrying these lines across the broad surfaces afterwards. Do this even though the lines are not needed on the edges. The gain in accuracy will repay the extra labor.

The hand-rests (Fig. 32, right) are to be made of five-eighths-inch stock, and should be two inches in width by eleven and one-half inches long. The corners should be cut as in the previous pair to one-half an inch each way along the edge and end.

Five one-inch dowel rods are needed.

It is possible to get these in one long piece if you happen to live near a mill, and then all you need do is to saw off the desired lengths. How ever, if they cannot be obtained easily, you can make your own. The pieces may be sawed to the approximate length first, or two or more may be got out in single pieces.

Two rods, each eighteen and one-quarter inches long; two rods, each twenty and one quarter inches; and one rod, twenty-two and one-quarter inches, give the exact lengths. It will be well to cut each piece several inches longer, so that the ends which are imperfectly formed may be cut off.

Rip out and square up pieces to full one-inch width and thickness. By "full inch" is meant enough over the inch to allow sandpapering without getting below the inch.

On one end of one piece, draw pencil lines connecting corner with opposite corner; that is, draw the diagonals. Now set a pencil gauge so that the distance shall be the same as one half of the diagonal. Gauge from each edge each way, making two lines on each surface. Plane each of the four corners down to the gauge lines. This gives an eight-sided solid. A stroke or two of the plane on each of the eight edges will leave the solid so that it can easily be sandpapered to a cylinder.

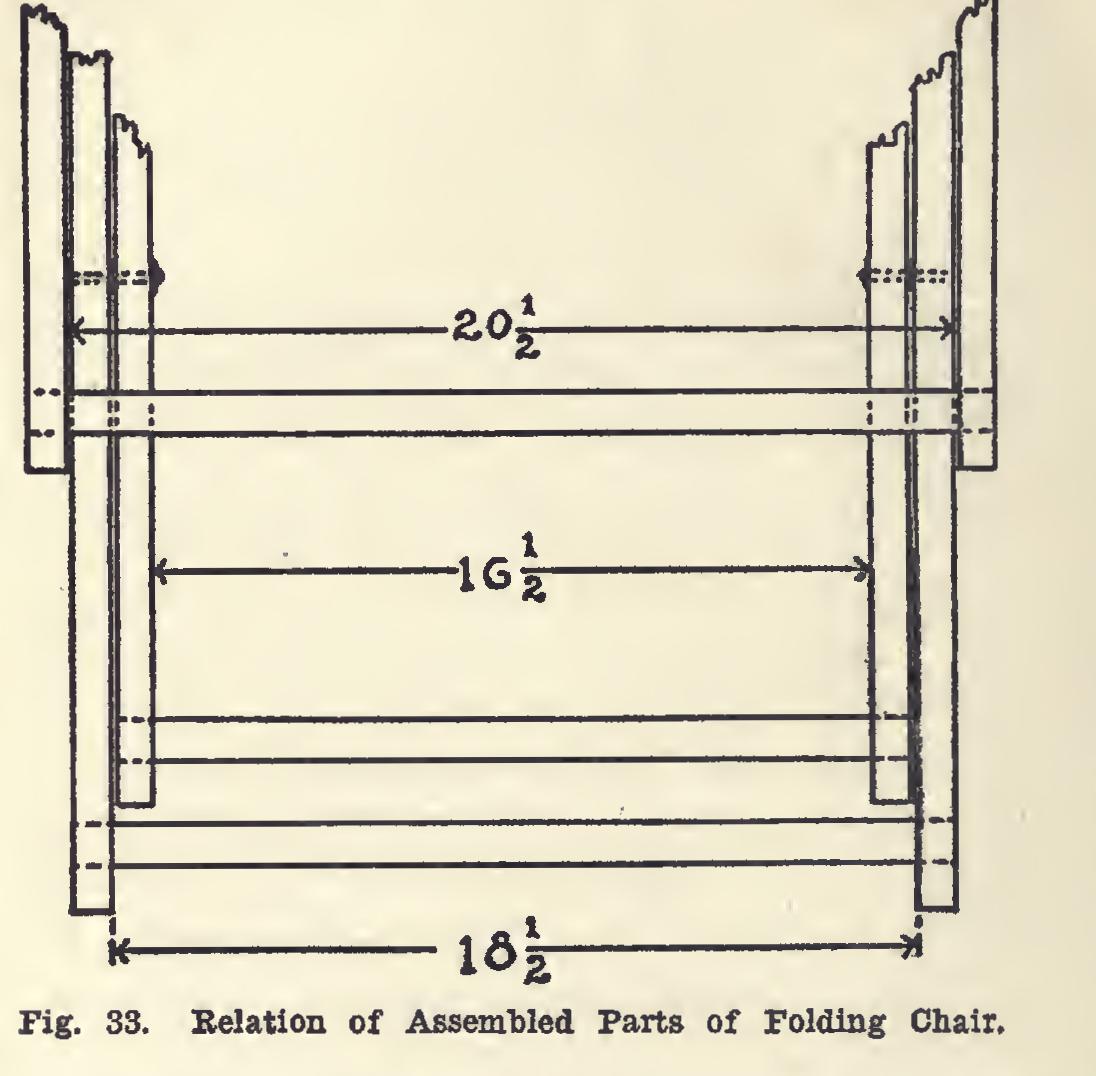

Fig. 33 shows the relation of the parts when assembled. The shortest pair of rods connect the pieces which support the seat; the next in length connect the pieces which support the back; the longest rod is for the pieces by which the back is adjusted.

These rods should fit tight, and may be fast ened in addition with a small screw or nail from the under or back side.

The hand-rests should be nailed to the arms with small nails or brads, before the arms are bolted. The photograph, Plate 7 (A), shows the relative positions.

The bolts should be of a size to fit snugly. Four of them must be of a length to accommo, date two seven-eighths-inch pieces of wood, a washer on each side, and at least one between the pieces; also, of course, the nut.

Two of them must be of a length to accom modate one seven-eighths-inch and one five eighths-inch piece and three washers.

The other two bolts must take on two seven eighths-inch pieces, one five-eighths-inch piece, and four washers, two of the washers being placed between the pieces of wood.

The canvas should be tacked to the rods in such a way that the tacks will be concealed. This can easily be done, because of the fullness given it. The ends should be folded back so as to give strength to the parts through which the tacks enter.

Common carpet tacks of small or medium size will do. They should be placed every few inches. The photograph shows how the canvas should be hung.

While the size of the chair may be varied, it will be necessary to keep the proportions if the parts are to fold properly.