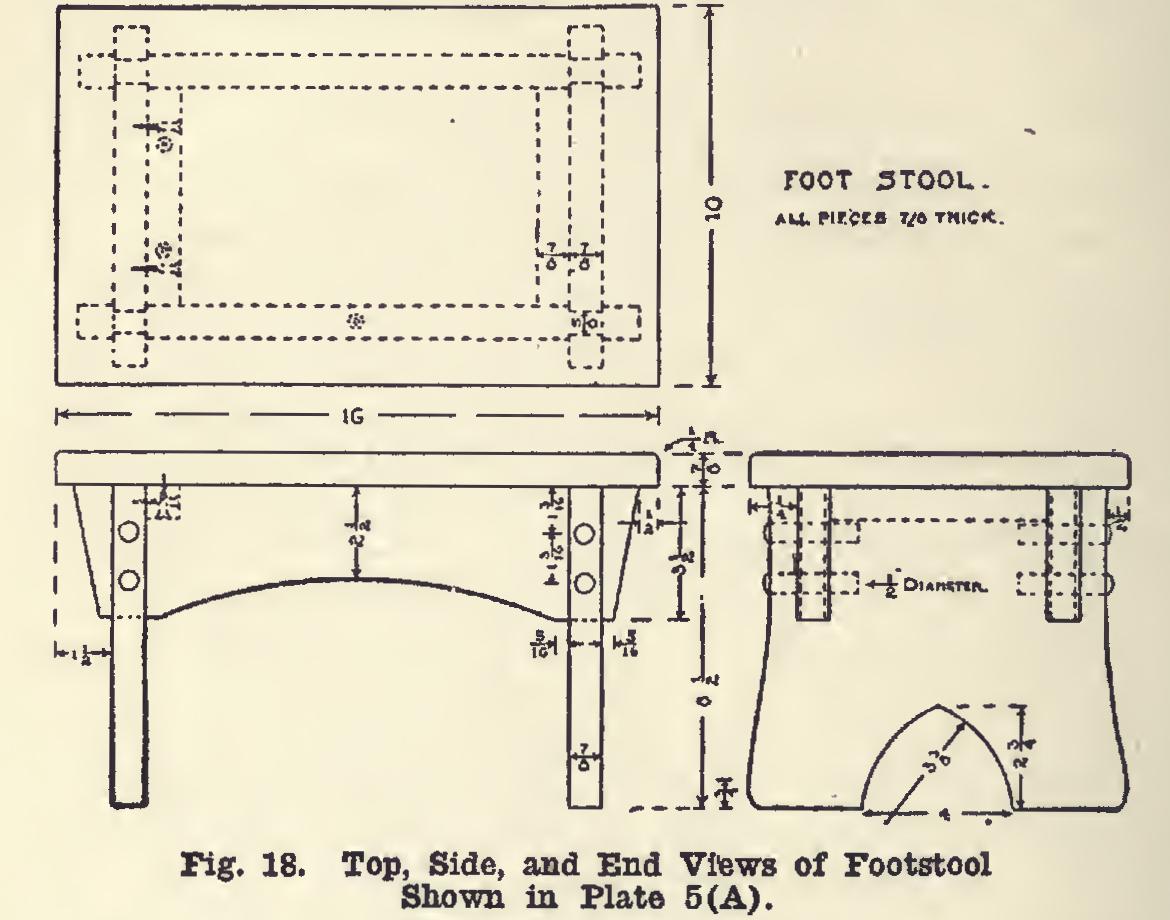

A Footstool

edge, inch, inches, line, lines and length

A FOOTSTOOL A footstool may be classed among the house hold necessities. It has a way of making itself useful to both old and young. Even the chil dren will be found using it in an inverted posi tion for a doll cradle, rather than the fine cradle bought for that especial purpose.

The design illustrated in Plate 5 (A) origi nated with the Handicraft Club, Peoria, Illinois, and possesses many excellent points. It is of good size, has a base of such size as not to admit of being easily toppled over, is substantially con structed, and, above all, is well-proportioned in its parts. The top, being of solid wood, will not show wear as would an upholstered one.

It should be made of oak. Red or white oak will do, and it may be quarter- or plain-sawed. It will be well to purchase the necessary stock in one piece, which should be mill-planed to a thickness of seven-eighths of an inch. It must be well seasoned, free from warp, knots, and checks, and clear the full length of the piece. As some of the pieces are to be finished to a width of ten inches, it must be at least a quarter of an inch wider. The length will be four feet two inches.

Begin by squaring, in the usual way where the stock is mill-planed, one piece to a width of ten inches and a length of sixteen inches. This is for the top. Round off the top edges on a one quarter inch radius after having planed off the surface so that it is smooth and free from ridges and hollows made by the planer.

The two stretchers or side pieces may next be got out. Square them to a width of three and one-half inches each. As the ends are to be cut on a slope, it will not be necessary to square them, nor to cut to length. To lay out these slopes, square a line across the face of one of them close to an end, keeping the beam of the try-square against the joint-edge. Measure from this line, along the edge opposite the joint edge, seven-sixteenths of an inch. Set the bevel —or "bevel-square," as it is commonly called— so that the beam shall rest against the joint edge; and move the blade until it shall pass through the point just located on one edge, and, on the other edge, through the point at which the try-square line meets the edge. Mark the

two ends on the two surfaces of each, using the try-square to carry the line across the edge. From the long point of the slope, measure fifteen inches, and lay off the slopes on the second ends. These ends may be sawed and planed to the lines now. To lay out the curve on the lower edge of the stretchers, three points are given. Measure from each end one and one-half inches along the shorter edge, and mark. Locate the middle of the longer edge, and measure across the sur face two and one-half inches, and mark the third point. The curved line may be sketched free hand through these points; but a better way would be to lay it out by means of a "sweep." The length is found as follows: Connect the three points with straight lines (Fig. 19). Lo cate the middle of these two lines, and holding the square with its tongue along the line, and the blade passing through the middle point, draw a line along the blade. The distance from the point at which the two blades cross, to any one of the points, gives the radius of the circle of which the curve is a part. Cut out the curve with the turning saw, and smooth with the spokeshave and scraper.

The top view (Fig. 18) shows that the legs fit into gains on either side of each stretcher. These gains may next be laid off. Along the shorter or lower edge, measure from each end five-sixteenths, then seven-eighths of an inch. If the thickness of the legs is made less than seven-eighths of an inch in smoothing the sur face, the last distance must be shortened accord ingly. Square knife lines through these points. The pieces should be placed together and the lines marked on each side, at each end of both. Gauge for depth of cut, one-eighth inch first, then three-quarters inch, from the same side.