A Mission Chair

inches, gauge, rails, edges, set, tenons and fig

Having marked the mortise locations, square lines across the broad faces at these places, to correspond with those drawn across the edges. Square across both faces of each piece. To lo cate the sides of the mortises which are on the broad surfaces, set the gauge to one inch, and gauge them with the gauge-block against what is to be the outside edge of each. As these mor tises are to extend entirely through the leg, they are to be laid off on both sides. Fig. 48 shows between what lines the gauging is to be done. Make all the marks on all the legs that can be made with this setting of the gauge; then reset it to one and one-half inches, and gauge with the block against the edges as before.

For the side of the mortises which are to be made on the edges of the legs, set the gauge first to five-eighths of an inch, and mark, keep surfaces. Reset to one and one-eighth inches, ing the gauge-block against the outer broad and, with the block against the same surfaces, repeat. Cut these mortises with a one-half-inch chisel. Cut the mortises in the edges first.

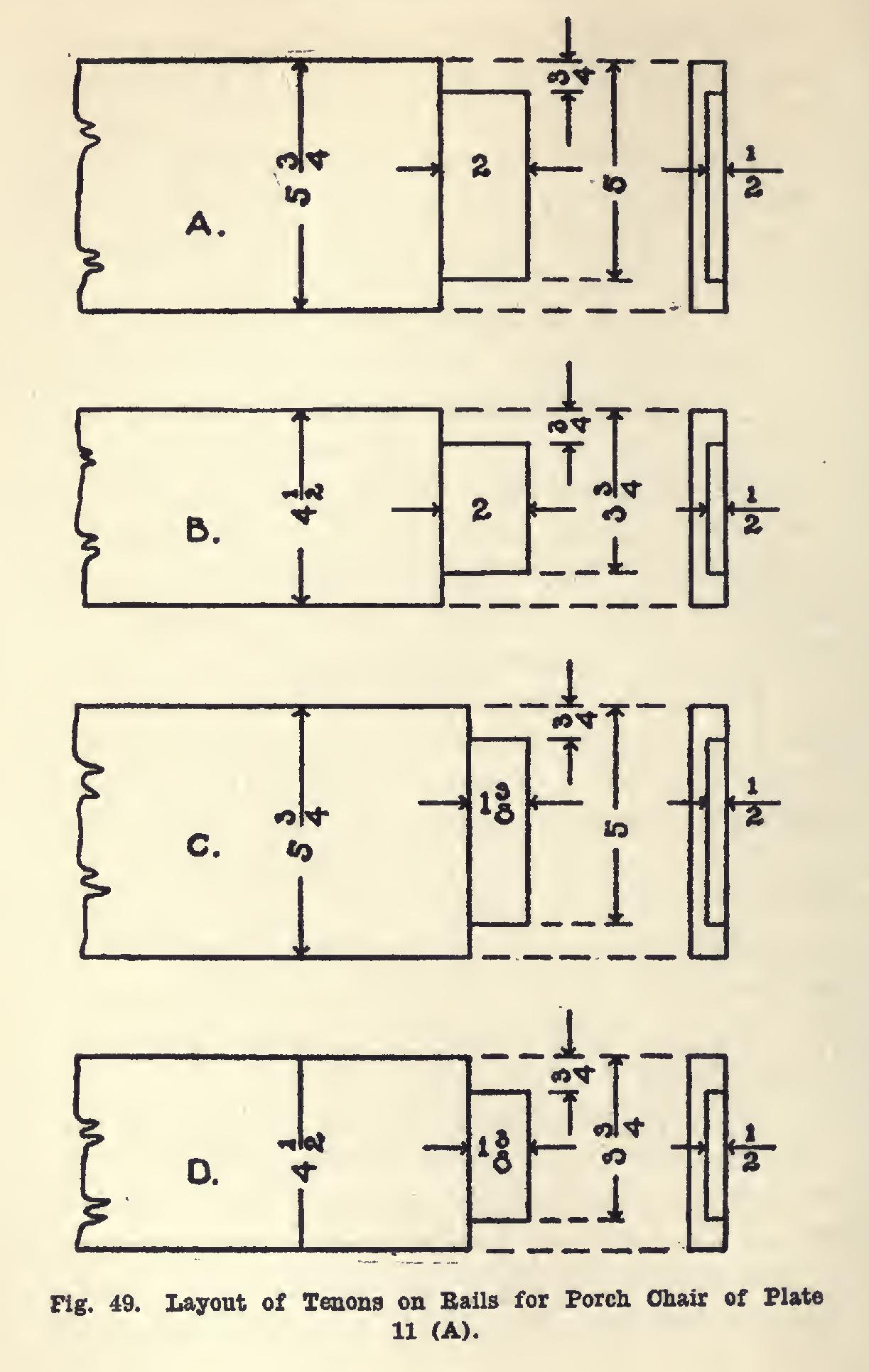

Fig. 49 gives the layout of the tenons. At A are shown the tenons for the front and back lower rails. Stand the rails on the edge, and even the ends. Measure from one end two inches, and square a sharp knife line across the two upturned edges. From this line, measure twenty-six inches, and repeat. There should remain two inches from this line to the remain ing end of the piece. Square knife lines around each end of each piece, to correspond with these lines.

Next set the gauge to three-quarters of an inch, and, with the gauge-block against the joint-edge, gauge on the ends and on the sides as far as the cross knife-marks. Now set the gauge to five inches. Keep the gauge-block against the joint-edge, and gauge as was just done. With the gauge set to one-half an inch, and the block held against what is to become the outside surface, gauge across the ends and down the edges far enough to meet the knife lines.

The tenons for the top back rail are laid off similarly (B, Fig. 49), except that in the second step of gauging the gauge is set to three and three-quarters inches, instead of five inches.

The tenons for the lower side rails are shown at C, Fig. 49. The layout is similar to that at A, the difference being in the length of tenon.

At C the tenon is one and three-eighths inches, instead of two inches as at A. Again, the dis tance between the shoulders of the tenons for these rails is but twenty-one inches, instead of twenty-six inches, as at A.

Fig 49 (D) shows the tenon for the upper side rails. The length of tenon is the same as at C. The distance between the shoulders is the same, twenty-one inches. The gauge in the second step is set to three and three-quarters inches, however, instead of five inches.

The manner of cutting the mortises has al ready been described and need not be repeated. It is suggested that a one-half-inch chisel be used, that the chisel may be of the same width as that of the mortise. The tenons are best cut with the tenon saw, and nothing but the most careful cutting to a neat knife-mark will look well or fit well when the parts are assembled.

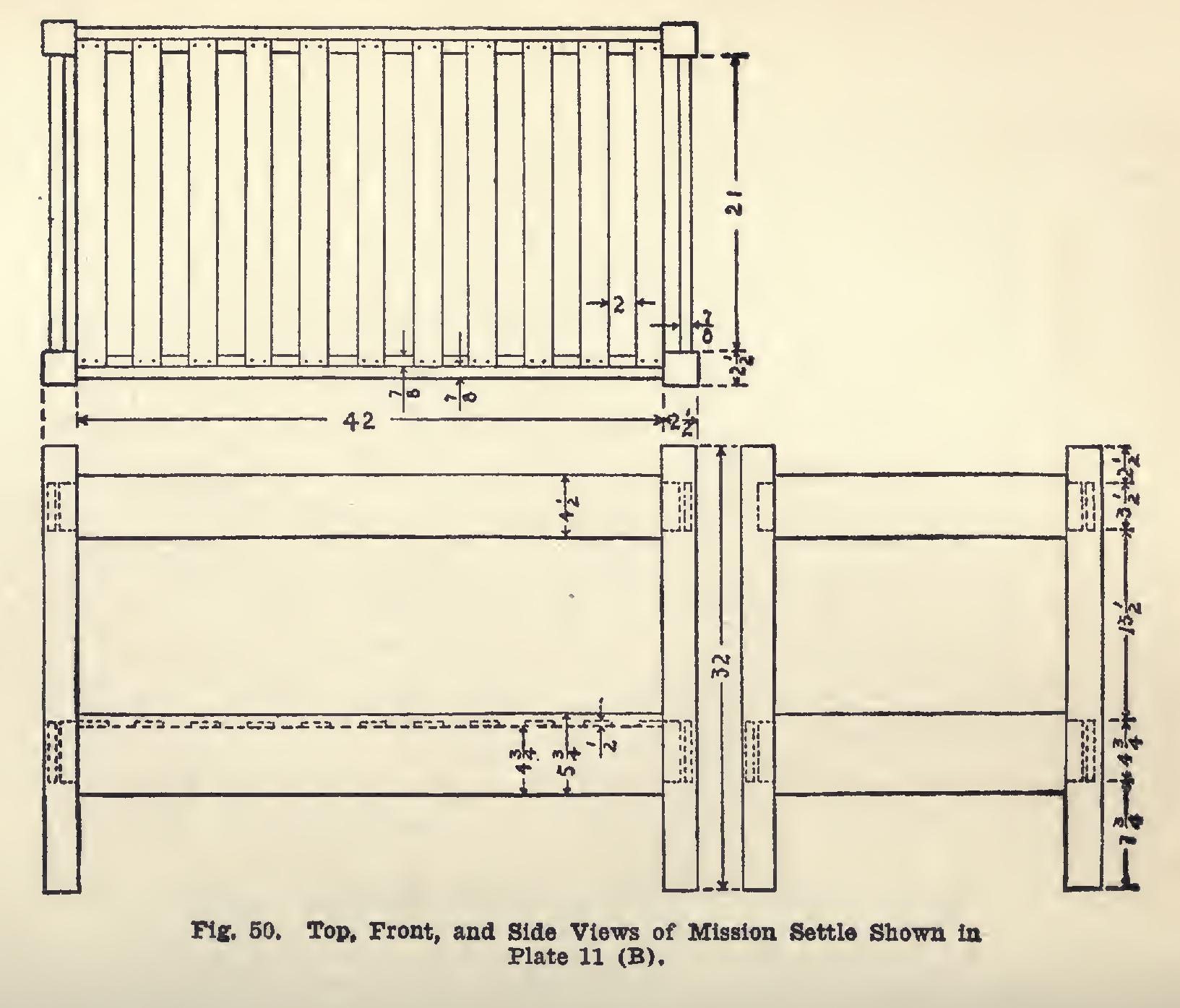

Put the sides of the chair in the clamps first, using only the best glue. Allow these to stand over night; then put in the other three rails. Measure the diagonals—that is, from one leg to another across the center of the framework —and see that they are equal. Put in a spread stick diagonally, if necessary, to hold the frame in proper position.

After the clamps have been removed, fit the five-eighths-inch pieces so that they will just go between the legs, and fasten them to the front and back rails (Fig. 47) by means of screws. The top edges should be about one inch below the top edges of the rails, and parallel to them.

The slats of three-eighths-inch stock may next be fitted between the front and back rails. They are to be spaced two inches apart, the first and last being pushed tightly against the legs.

Small nails should be used to fasten them to the pieces just screwed to the front and back rails.

Nothing works up into mission furniture better than plain sawed red or white oak. Many stains are on the market for producing mission effects upon oak. The extremely dark, almost black, effects have held sway for a compara tively long time, and are quite common at present. There is a tendency, however, to break away from the somber colors, and rich browns are much in evidence.

Directions for filling and finishing the wood will be found upon the cans containing the finishes, and should be carefully followed.