A Three-Part Screen

square, pieces, lines, inches, inch and piece

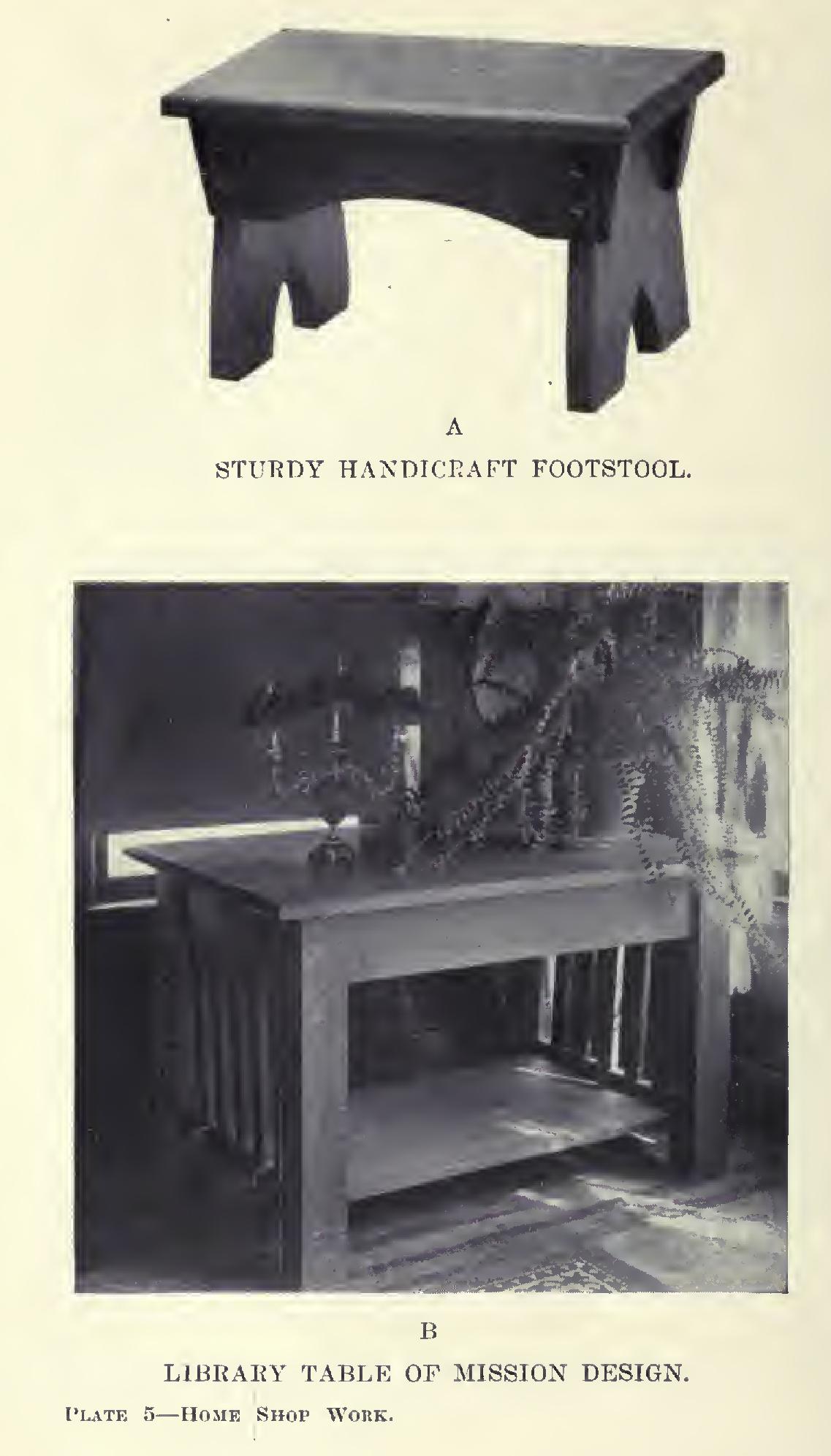

A THREE-PART SCREEN Usually, one or the other of two objections may be applied to store-bought screens. They are so heavy that they cannot easily be moved; or, if not heavy, they are so weak structurally that they will not stand rigidly.

The design illustrated in Plate 4 is singu larly free from either of these objections. The frame is light, being made up of seven-eighth inch square pieces. The panels are filled with art burlap or monk's cloth, stretched on light frames of three-eighths-inch whitewood. The oak parts are thoroughly mortised and tenoned together.

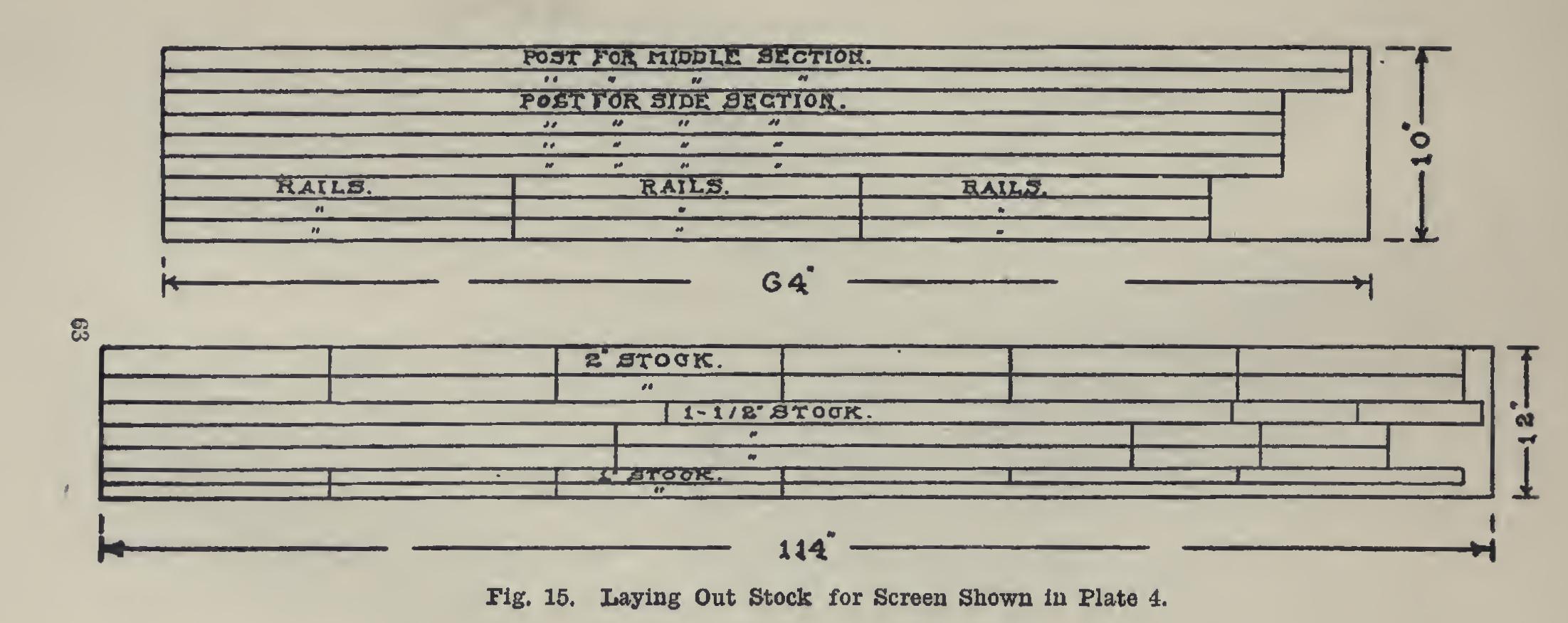

It will be found more economical to buy the stock in as few pieces as possible. For the oak uprights and rails, secure a board, mill-planed to seven-eighths of an inch, with a width of ten inches and a length of sixty-four inches (Fig. 15, upper part). Red or white oak may be used, and it may be quarter-sawed or plain.

For the frames which are to support the burlap there will be needed a piece of yellow poplar, mill-planed to three-eighths of an inch, with a width of twelve inches and a length of nine feet six inches (Fig. 15, lower part).

Smooth the two sides of the oak board with smoothing plane and scraper. Remember that the stock is of such thickness as to allow of no more being planed off than just what is neces sary in order to remove the mill marks.

To get the most out of the board, and save time and labor as well, joint—that is, straighten and square—one edge of the board. Set the gauge to seven-eighths, and gauge and rip close to the line. Plane to the gauge-line on this piece. Repeat until nine pieces the length of the board have been obtained, marking each with face marks.

From these pieces select four, and square one end of each. Place these pieces on the bench, side by side, and even the squared ends by means of the try-square. Measure from the squared ends fifty-eight inches, and square a sharp pencil line across the four pieces. Now separate, and square these lines entirely around each piece. These lines locate the lower edges

of slopes of forty-five degrees, which are to be placed on the tops of the uprights.

Before sawing and planing these slopes, select two more pieces. These are for the up rights of the middle section. Square the ends, and measure from them sixty-one and one-half inches, squaring lines entirely around each piece at this point.

These slopes can best be laid off by means of the bevel. Set the blade to an angle of forty five degrees by holding the beam against the blade of the steel square and moving the blade of the bevel so that it shall rest upon similar marks on blade and tongue of the steel square.

With the bevel, mark the slopes on opposite sides of each piece. Saw close to these lines, and finish with the plane. This shapes the ends like a house roof with gabled ends. Connect, with straight-edge, the middle of the ridge to the four corners; and chisel or saw, and then plane to these lines.

Prepare the cross-rails by sawing off nine pieces of the stock squared to seven-eighths inch by seven-eighths inch, to a length of eighteen and one-half inches each. These pieces have tenons on each end. Care should be taken to saw them off square and to the lines, so that no end planing need be done.

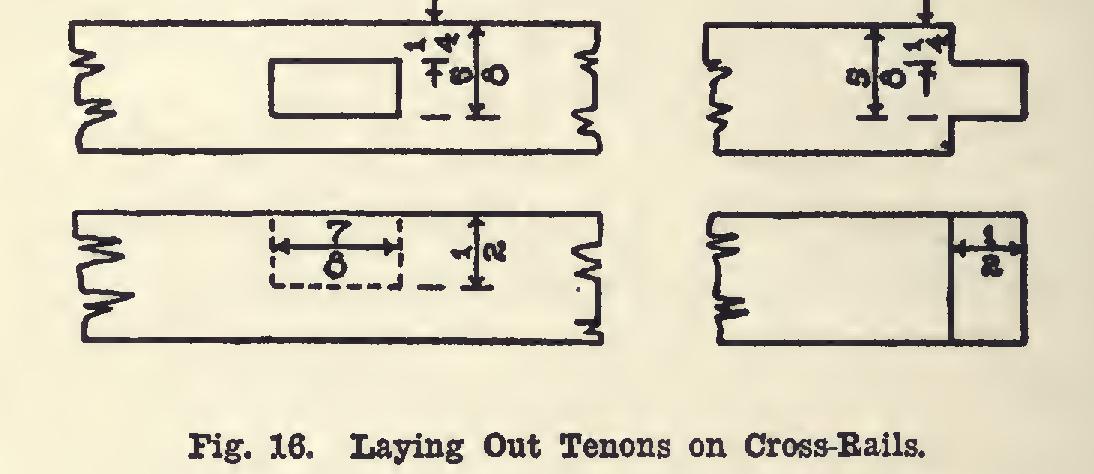

These tenons may as well be laid off and sawed now. Place the nine pieces on the bench side by side, and even the ends with the try square. If it is not found convenient to handle so many at once, take a fewer number. When the first lot has been marked, one of these may be placed with the second lot, to insure their having the same length. From one end, meas ure one-half inch; and from this point, seven teen and one-half inches. Square knife lines across the lot at these two points; set the gauge first to one-quarter of an inch, and gauge from a face side on two opposite sides as far back as the knife lines, and on the ends of each piece at each end (Fig. 16). Again, set the gauge to five-eighths, and gauge as before.