A Three-Part Screen

inches, pieces, lower, inch, frames, lines, one-half, set, seven-eighths and nails

With the tenon saw, rip the tenons to thick ness, and crosscut the shoulders.

The mortises of the four uprights of the same length may be laid out together. Place the pieces side by side, with the lower ends even and the pieces turned so that they pair. One set of face marks on all pieces must, when the parts are assembled, be on one and the same side of the frame, while the other set must fact "in." In marking for the mortises, the "in" faces should be turned upward.

Measure from the lower end four and one half inches; then from this mark, seven-eighths of an inch; from this, thirty-nine and three eighths inches; from this, seven-eighths of an inch; then, ten inches; finally, seven-eighths. There should remain one and one-half inches to the lower edge of the bevel. Square knife lines across at these points.

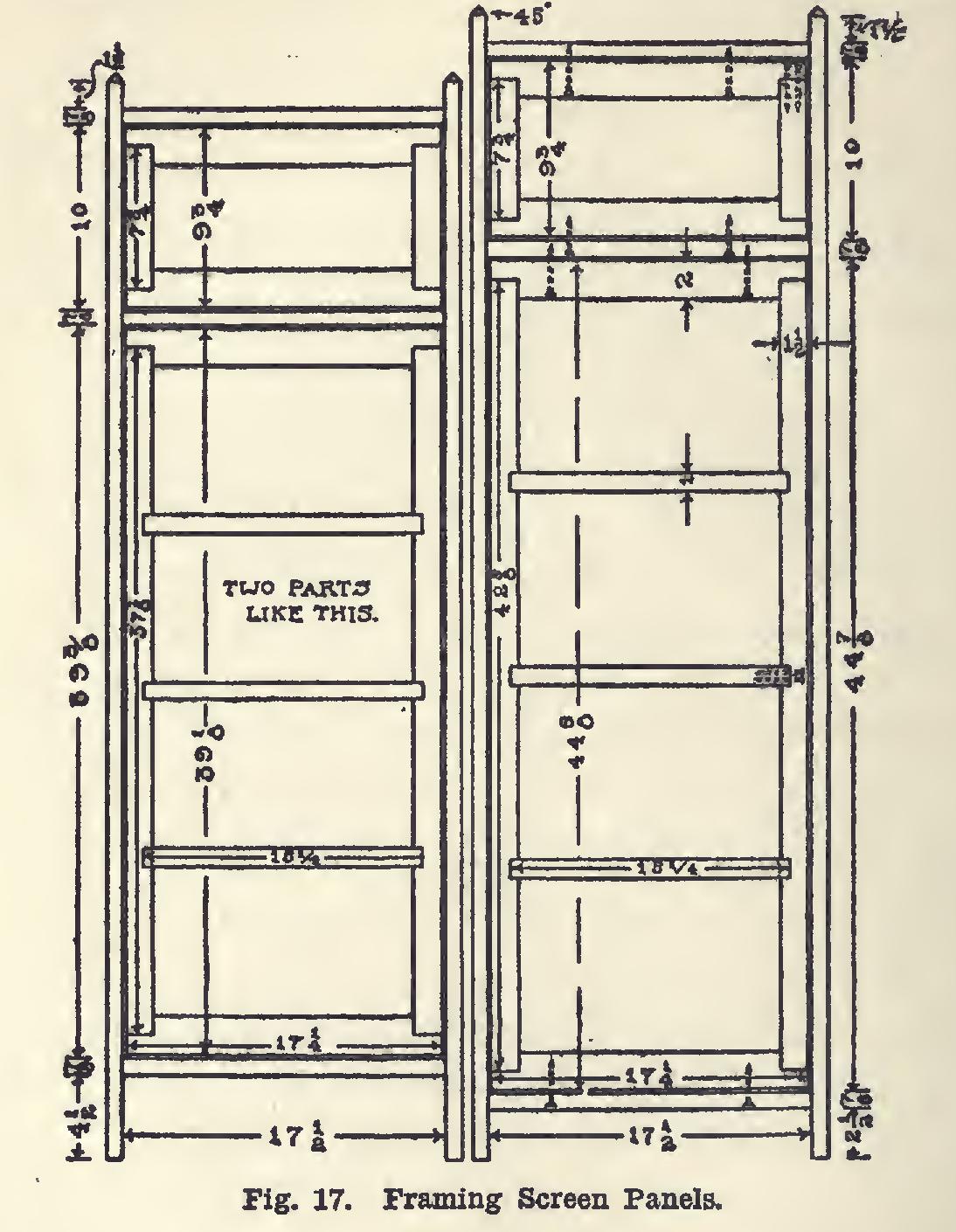

Pair the two longer uprights, and measure on the "in" faces as follows: From the lower end, two and one-half inches, seven-eighths, forty-four and seven-eighths inches, seven eighths, ten, finally seven-eighths of an inch. There should remain one and one-half inches. Carry the lines across at these points (Fig. 17).

Between the lines which are seven-eighths of an inch apart, gauge from the face with the gauge set first to one-quarter, then to five eighths of an inch.

Cut these mortises with a three-eighths inch chisel to a depth of one-half inch full. Keep the ends of the mortises clean-cut and sharp; otherwise they will show badly. Scrape and sandpaper the pieces carefully.

Glue and clamp the parts together, taking care to place the faces either "in" or to one and the same side. Use the steel square to test the corners while clamping; and so place the clamps that the faces will be level when the straight edge is placed across any two pieces at a corner.

When these have set over night, scrape off the surplus glue, and stain and fill as desired. When stain and filler have dried, the parts may be waxed, or, if preferred, given a very thin coat of shellac. There are many prepared stains on the market now. As these pieces are small, no trouble will be had in following the direc tions which always accompany these prepared stains.

The hinges are the kind called "double-act ing," and allow the wings to be swung either way. The lower ones should be set about seven inches above the floor, and the upper ones about six inches below the top of the side wings. In fastening the hinges, but one screw-hole for either side can be seen. Put the screw in this one, swing the hinge, and the other will ap pear.

Now for the whitewood frames which are to support the burlap. Three of them are to be of the same size.

Time will be saved by ripping up the three eighths-inch board to the proper widths (Fig. 15, lower part). Joint, gauge, and rip as was dome with the oak.

For the three like frames, there will be needed six pieces two inches wide by seventeen and one-quarter inches long. Saw accurately and squarely, as no end planing is to be done on any of these pieces. Also six pieces one and one-half inches wide by seven and three-quar ters inches will be required.

For the lower frames of the two wings, get out four pieces one and one-half inches wide by thirty-seven and one-eighth inches long. For the lower center panel, two pieces of the same thickness, with a length of forty-two and five eighths inches, should be squared up. In addi tion to these pieces, the three lower panels will require six pieces two inches by seventeen and one-quarter inches, and nine pieces one inch by fifteen and one-quarter inches.

Fig. 17 shows the manner in which the upper panels are framed. Lines are square around the two-inch pieces at one and one-half inches from each end. The gauge is then set to one inch, and lines gauged from what are to become the outer edges, as far back as the knife lines. The tenon saw is used to rip and crosscut these corners.

Very thin wire nails are used to fasten the parts together.

The corners of the lower panels are framed in the same way. The side pieces are prevented from being sprung together when the burlap is drawn tight, by having three one-inch cross pieces framed into them to a depth of one-half an inch. Place the four like side pieces on edge, even the ends, and measure and mark. Square two lines an inch apart at the middle of the pieces, lengthwise. Also put lines an inch apart at the middle of the two resulting spaces. Square these lines across the faces; gauge for depth; saw and chisel. The two side pieces of the lower central panel may be similarly laid out and cut.

The designer shows his ingenuity in the way he fastens the panels so that the fastener shall not show.

Before the frames are covered with burlap, the two rather stout wire nails are firmly fixed in the top rails as shown in Fig. 17. They should project not over one-half an inch. Correspond ing to these nails, holes just large enough and deep enough to receive them are bored in the top and middle rails, from the under side.

Two nails are now firmly set in each of the middle and lower rails (Fig. 17) so that their points shall extend upward about half an inch —or it may be more in this case. After having marked and bored holes in the lower rails of the burlap frames, drive these nails back so that their points are flush with the surface.

Cover the frames, using small carpet tacks for fastening. The burlap is to be drawn over both sides and tacked in the edges of the frame. The tacks will then be hidden when the frame is in place.

The burlaps come in a great variety of colors; a soft or dull green or brown will look pretty. Monk's cloth makes the best covering.

Having covered the frames, insert the nails, which they contain, in the top rails, into the holes prepared for them in the oak. The upper frames must be put in place first, of course. Drive up the nails, which were placed in the middle oak rails, into the holes made for them in the burlap frames.

In like manner place and fasten the lower burlap frames.