An India Stool

inch, holes, tenons, rod and legs

The holes for the dowel pins are laid off one half inch from the sides of the legs, and one-half inch from the ends of the mortise (Fig. 97, A). They are bored entirely through the legs, but not until the tenons are in place.

The holes for the large rods which support the seat are bored in the middle of the legs, three-quarters of an inch from the lower edge of the slope to the center. There are but two of these in each leg, and they are on the sides not marked XX. A one-inch bit is used, the holes being bored to a depth of three-eighths of an inch.

To make the tenons, measure from the end of each rail two inches, and square a knife line on the four sides (Fig. 97, B). From this line, measure fourteen inches and repeat. There should remain two inches of rail for the second tenon. Set the gauge to one-fourth of an inch, and gauge from the working face on both edges, and also on the ends of each rail. Now set the gauge to five-eighths of an inch, and gauge as before. This lays off a tenon of the same width as the rail, with a thickness of three-eighths of an inch and a length of two inches, with shoul ders on two sides.

Rip carefully to the gauge-lines with the tenon-saw, and crosscut to the knife lines. Bevel the ends of the tenons slightly, to insure their entering the mortises easily.

Fit the tenons into the mortises, marking each, as soon as fitted, in such a way that no two tenons shall be fitted to the same mortise. A good way is to letter a tenon AA, and its mortise AA; another BB, etc., keeping the XX faces out and up while fitting.

Scrape and sandpaper well; then put two sides of the frame together, using cabinet maker's clamps to hold the legs in place until the three-eighths-inch holes for the dowel pins have been bored, and the pins driven in place.

Glue is not necessary with this construction. Place the remaining rails and rods in place, and fasten as just described.

A good finish may be obtained by filling with golden oak paste filler, applying one coat of thin shellac, followed with two coats of prepared wax. No stain is necessary prior to the filler, for a filler can be purchased which contains suffi cient coloring matter. Allow the filler and shel lac each to dry over night. Rub the wax well after each application, with a flannel cloth.

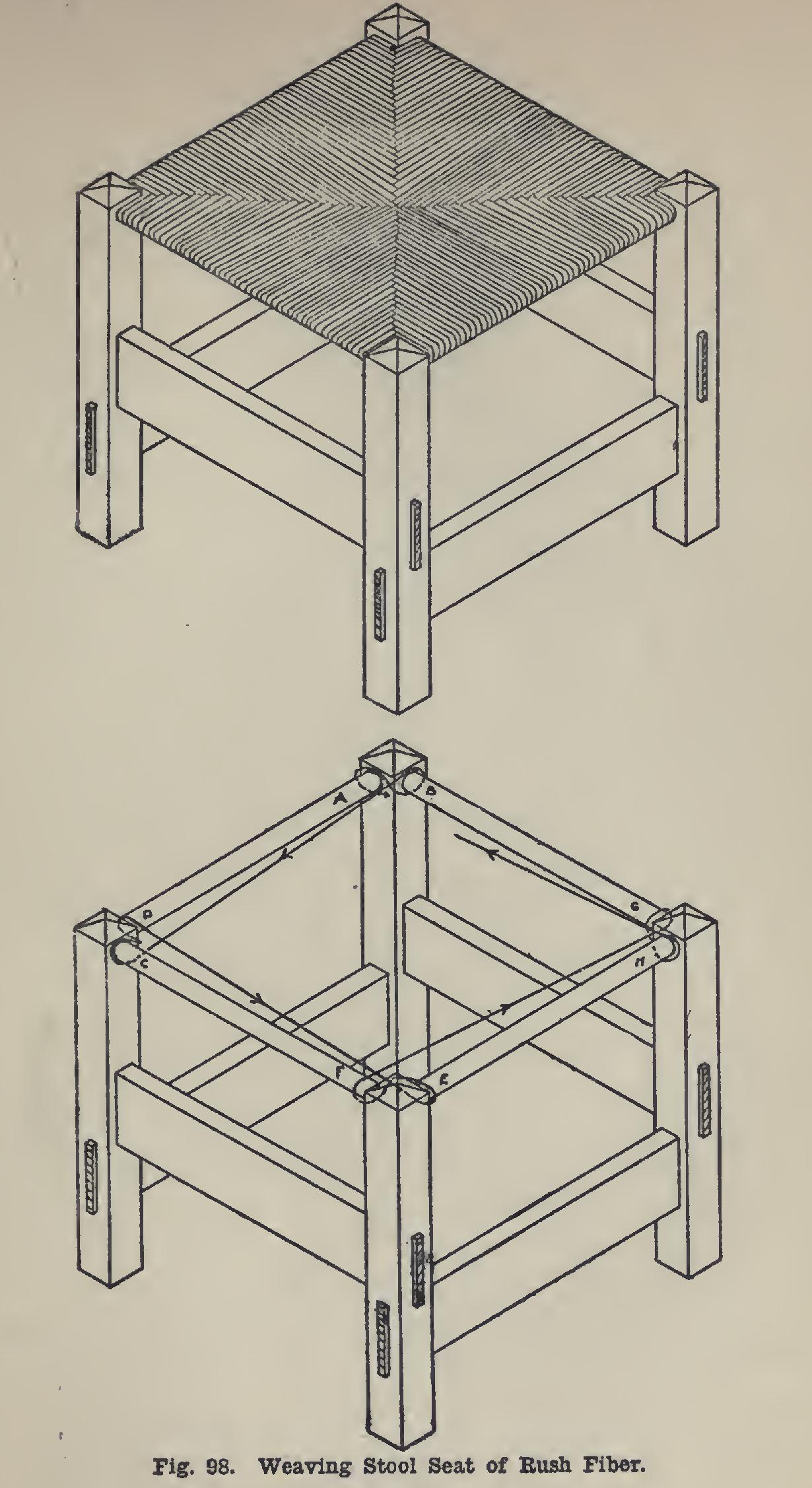

The most satisfactory thing for the seat is obtained by taking rush fiber, and weaving it around the dowel rods as shown in Fig. 98. Be gin by fastening one end of the fiber to the post as at A. Carry the cord around the nearest dowel rods (as at A), carrying it under, then over. Now carry it around the adjacent rod (as at B), passing it under, then over, the rod. Next carry the cord entirely across the stool to the opposite rod, passing it under, then over (as at C). Pass it around the adjacent rod (as at D). Now carry it entirely across the stool to E. Continue in this way until the seat is com pleted. Always pass the cord under from the inside, then over the rod. Keep the strands pressed closely to the legs in starting, and against one another.

The leather seats shown in the accompanying plate (Plate 20, A) are cut large enough to lap under the rods about one inch. An eyelet punch is used to put holes along the edges of the leather we inch apart. Eyelets are inserted, and mason's cord is woven through these back and forth.

Other ways of making the seat for this stool will suggest themselves.