Settle of Mission Design

legs, inches, marks, line, xx and gauge

SETTLE OF MISSION DESIGN In every furniture store can be found many pieces of what is known as "Mission" furniture, so called because it resembles the furniture found in the old Spanish missions.

Mission furniture has much to commend it. Its simplicity of line, honesty of construction, and quaintness of finish make it deservedly pop ular with those who have become tired of the highly ornamented pieces so common a few years ago.

There are extremes in everything, and, while one would hardly be wise to furnish his house entirely in this heavy style, yet a few odd pieces will help the looks of any room; or a whole room might appropriately be furnished in this style.

The settle shown in Plate 11 (B) and de tailed in working drawings in Fig. 50, was made by a home craftsman. The leather cushion was bought at a store, but might have been home made. It is laced together with thongs. The color of the cushion is a dark brown, while the lacings are a light or orange yellow. These cushions can be obtained in almost any color to suit the finish of the wood.

This particular settle was finished by apply ing a coat of brown Flemish water stain, slightly diluted with water. After the stain had dried, the wood was sandpapered lightly with fine sandpaper, and a coat of dark brown filler put on. Three coats of floor wax gave the finish desired.

Oak was used because of its beautiful grain; chestnut would have done as well.

The four legs are to be squared up to two and one-half inches in width and thickness by thirty-two inches in length. Too much care cannot be taken in getting the sides square one with another, as any inaccuracy will cause trouble when the frame is put together.

Select the joint-edge and working face of every leg so that when the XX marks are placed outward with reference to the framework, the best surfaces shall face forward and outward. The same precaution should be taken in mark ing the faces of the rails.

The upper ends of the posts are beveled about three-sixteenths of an inch on every side, at an angle of forty-five degrees.

To lay off the mortises, place the legs side by side on the bench, with the back sides of the forward legs and the forward sides of the back legs up. Even the top ends by using the try

square along one of the sides and across the ends.

Measure from the top on one of the legs two and • one-half inches; and square a light, sharp pencil line across the four legs at this point. Again, measure three and one-half inches from this line, and square a line across. Measure from the line last drawn thirteen and one-half inches, and mark; then four and three-fourths inches. There should remain between the line last drawn and the end of the leg seven and three-quarter inches. These marks should be on the sides of the legs which have no XX marks on them, provided you intend to have the XX marks outward when in place.

With the try-square, continue these lines on every leg on the sides which are not marked X.X. Do not, however, mark the top two marks of the forward legs, as no rail goes across, and the marks would but add confusion.

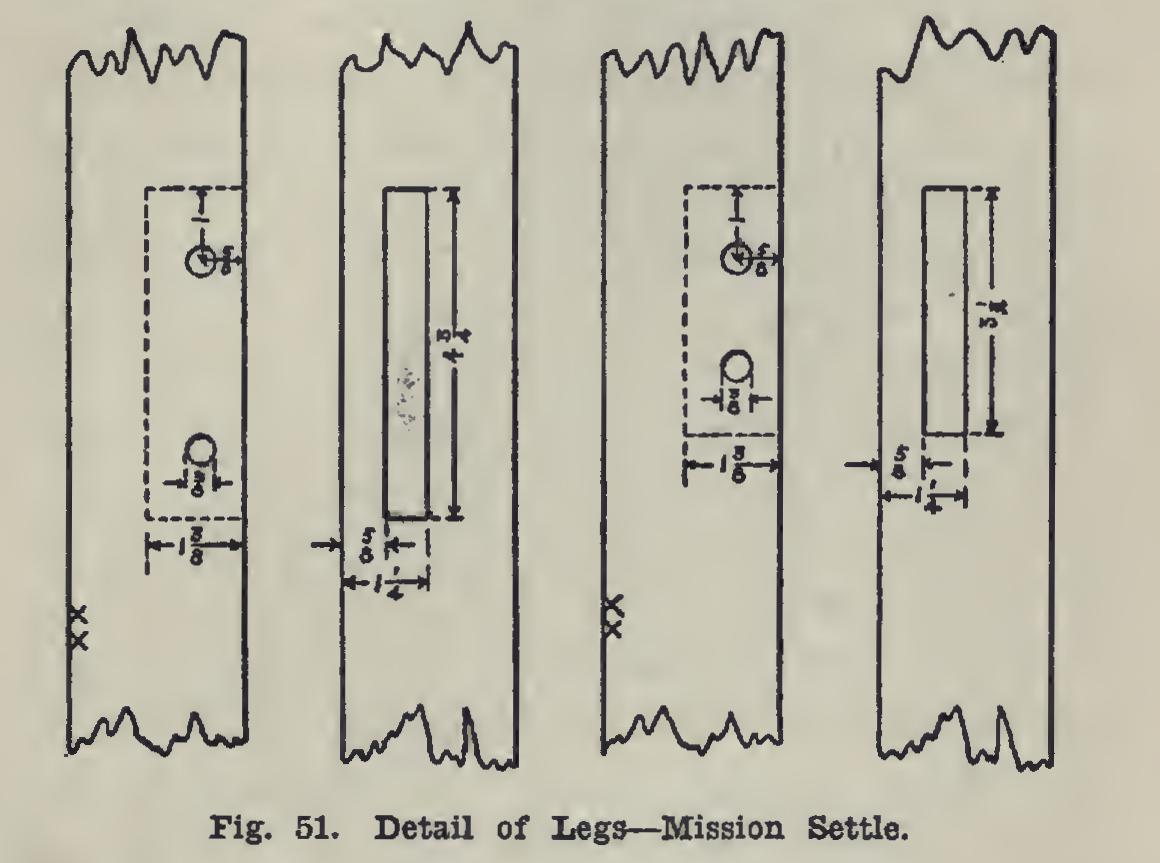

Set the gauge to five-eighths of an inch, and, placing the gauge against the XX sides (Fig. 51), gauge lines between the top two lines and also the bottom two lines, or on the three and one-half and four and three-quarter-inch spaces. Set the gauge to one and one-quarter inches, and gauge the same spaces from the same sides. No gauge marks should appear on the XX sides.

There are several ways in which to cut the mortises. Some carpenters use a chisel just the width of the mortise. A cut is made in the middle of the mortise as deep as possible, yet allowing the chisel to be worked loose easily. Another cut is then made near this one, a V shaped wedge being taken out. Alternate these cuts until the full depth is obtained; then set the chisel vertical, with flat surface next the uncut part, and take a cut full depth. This is con tinued to the end of the mortise, the wood being pried out as the cutting proceeds. The chisel is reversed, and the cutting is done from the middle to the other end of the mortise.