Stand

pieces, shelves, inches, gauge, stock, piece and joint-edge

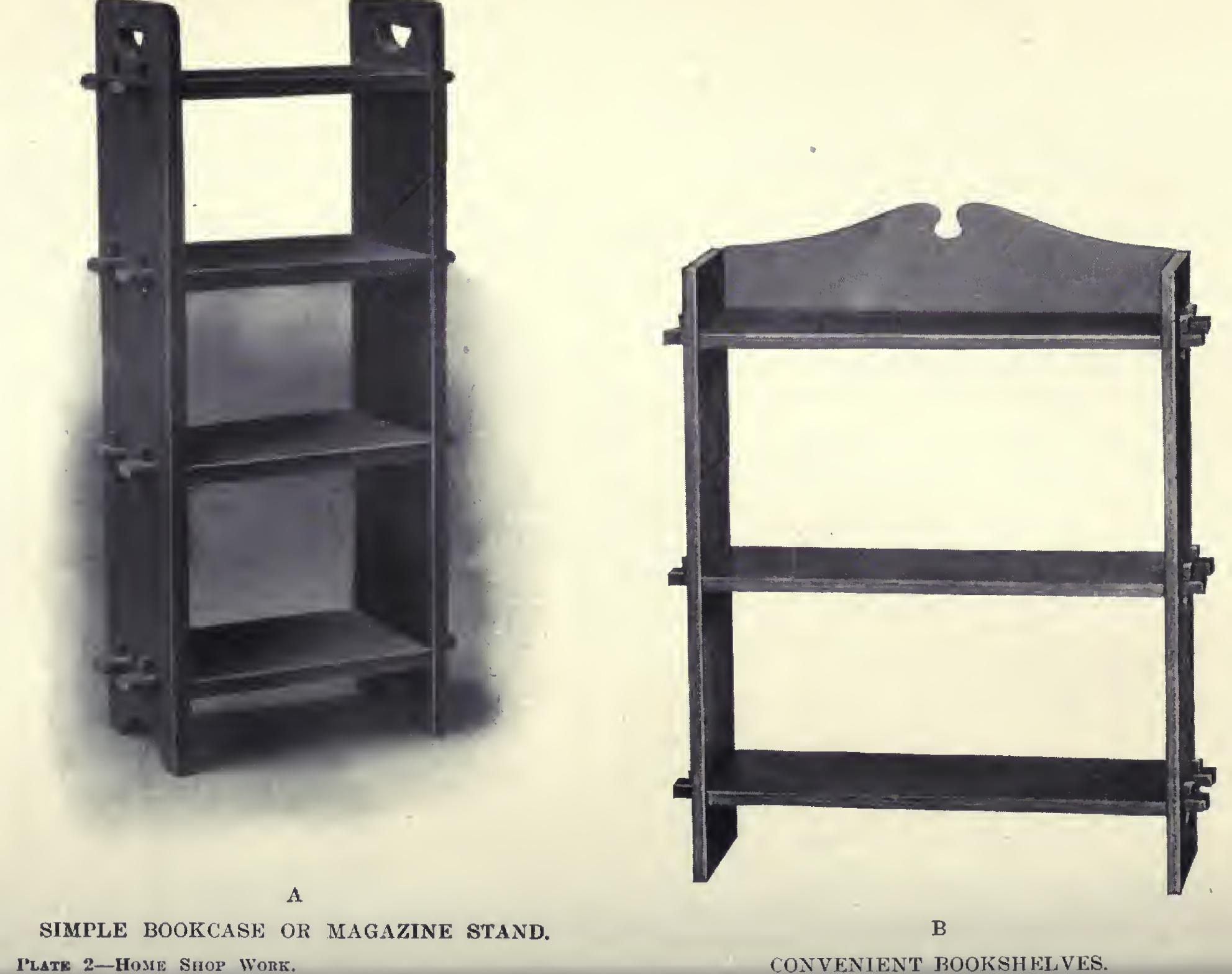

STAND A magazine stand is always a popular project; it is easy to make and is emphatically worth while. It makes a good piece to begin on. Plate 2 (A) shows one with keyed tenon fastenings and of the ever-popular craftsman design. Like all other craftsman designs, it is pleasing in its appearance because of its sim plicity and honesty. Such a stand would make a splendid place for keeping such books as are in constant use; in fact, it might be well used for both books and magazines.

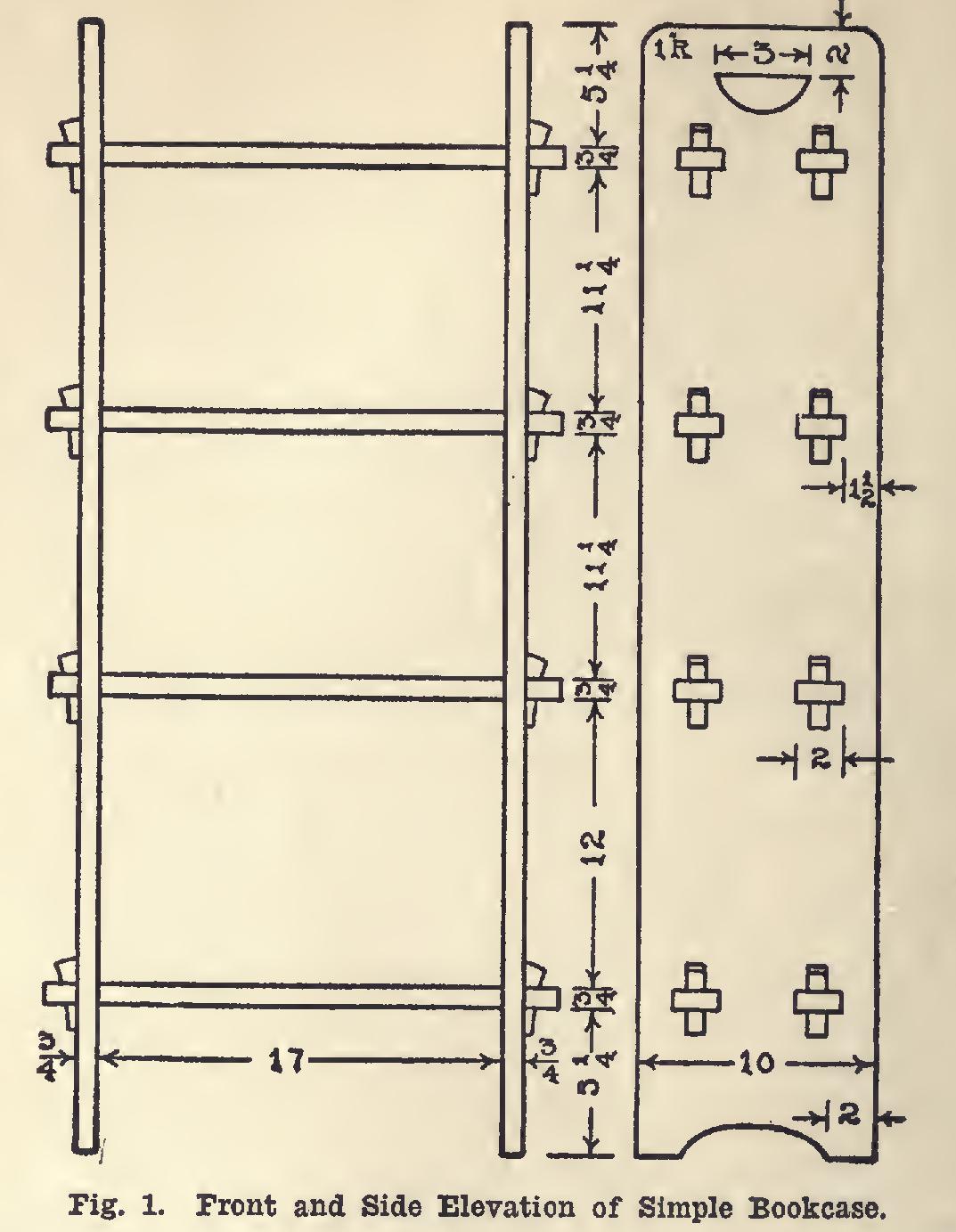

There will be needed for the sides two pieces that may be squared to a width of ten inches and a length of four feet. These and all the rest of the pieces are to be three-quarters of an inch thick when finished. For the shelves, square up four pieces to a width of ten inches and a length of twenty-one and one-half inches. Stock for the keys can, no doubt, be got from the waste made in cutting the other pieces.

Any kind of wood can be used; but since the design is so pleasing, and the stand will proba bly be placed in the living room when finished, it will be a good idea to get the best. The cost is but little more, and then one feels more like doing his best work when he is working on the best wood procurable. It is not necessary to procure mahogany. Most of our readers have access to quartered white oak, and this makes up into as pretty a piece of furniture as one could desire. If possible, have its two surfaces planed and sanded at the mill. It costs but very little more. The cheapest way to order stock such as this is to combine the different short lengths into one or more pieces of standard length, unless the mill man should happen to have some short lengths left from his own work that would an swer. Since all these widths are the same, it may be well to have the edges jointed also so that the proper width, ten inches, is obtained.

It is best for beginners to work with the rough stock. On the simpler pieces such as are suitable for those just starting to learn the use of the tools rough stock is specified. Every handicraftsman who hopes to attain real skill should be able to square up completely his stock from the rough, before beginning to use mill planed stuff. After he has once learned to do this without much trouble, it would be a waste of time and muscle to use the rough stuff when it can as easily be ordered mill-planed.

It is rather difficult to cut the tenons on the shelves and the mortises on the sides so that there will be no unevenness where their edges adjoin. That this may not show so readily, many mechanics would make the shelves slightly nar rower than the sides. This difference should not be greater than three-sixteenths of an inch on each side. The shelves would then need to be made three-eighths of an inch narrower, due al lowance being made in laying out the tenons.

Supposing the pieces are of the correct width and properly surfaced, begin by cutting the two sides to length, planing the ends smooth and square. Likewise cut the shelves to length.

Place the two side pieces (see Fig. 1) in the vise, edges up and ends evened; measure from the lower ends, and mark with a very sharp pencil, lightly, five and one-quarter inches, three quarters, twelve, three-quarters, eleven and one quarter, three-quarters, eleven and one-quarter, then three-quarters. There should remain five and one-quarter inches from this line to the end of the piece. Square lines across the edges at these points; then separate the pieces, and square lines across both sides of each piece, corresponding to the lines on the edges. The light, sharp pencil lines should still be used; knife marks would ruin the outer surface. Set the panel gauge to one and one-half inches. Keeping the head against the joint-edge, one edge of each should be marked for a joint-edge, even if it was jointed at the mill ; and gauge be tween the lines that were laid out three-quarters of an inch apart. The successive settings of the gauge for the other sides of the mortises can be figured easily from the drawings. Keep the head of the gauge always against the joint-edge, even while laying out the sides of the mortises farthest from the joint-edge. There is a very good reason for this. These markings should be laid out on both sides of each piece; and the shelves, if of the same width as the sides, should be prepared so they can be gauged with the same settings of the gauge. The same precaution about holding the gauge against the joint-edge holds good in marking the shelves, just as in marking the sides.