Umbrella Stand for the Hall

inch, gauge, copper, inches, set, block, surfaces and lines

Set the gauge at one-eighth of an inch (Fig. 107), gauge each side of each piece at each end. Next set the gauge to three-quarters of an inch, and as before. Be sure to keep the gauge block against the working face and joint-edge.

With the tenon saw, rip to these gauge-lines, and crosscut to the pencil lines. Make sure the shoulders of the tenons are square before you proceed further.

A miter of forty-five degrees should be cut on the ends. This can best be done with the miter-box. The long point of the miter should be seven-eighths of an inch from the shoulder of the tenon.

Place the posts upright, in the positions they are to occupy relative to one another, and mark in some way the approximate locations of the holes which receive the dowels, the mortises which receive the tenons, and the gains in which the drip-pan shelf enters its corners. Now, place them side by side, with the inside surfaces upward and even; and square the lower ends to the sides. Measure from the bottom of the posts five inches; from this point, seven-eighths of an inch; from this, four inches; then twelve inches; five-eighths of an inch; and, finally, four inches. There should remain one and one-half inches to the edge of the bevel which is on the top. Square sharp pencil lines across the four pieces at these points. Carry these lines across the remaining inner surfaces, using the try-square.

Set the gauge to seven-eighths of an inch; and, keeping the block against the inner surface, gauge on the remaining inner surfaces between the lower marks, which are seven-eighths of an inch apart. Do this on each inner surface of the four posts. Set the gauge to one-eighth of an inch, and gauge as before. This gives the depth of the gain or recess, while the first setting of the gauge gave the width.

For the sides of the mortises at the upper ends of the posts, set the gauge first to one quarter of an inch, and gauge from the outside surfaces upon each of the inside surfaces, be tween the lines which were laid off five-eighths of an inch apart. Then set the gauge to seven eighths of an inch, and repeat, keeping the block against the same surfaces as before.

Measure, and mark on the remaining lines the middle of the posts. These marks give the points at which to set the spur of the bit in boring the holes for the dowel rods. Chisel the gains, and cut the mortises.

Bore the holes for the dowels with a three eighths-inch bit. If possible, secure a bit one thirty-second of an inch smaller than the sup posed size of the dowel. Dowels shrink, and this will insure a tight fit.

Scrape with the steel scraper, and sandpaper all the parts before putting them together.

Put a touch of glue on the ends of two of the dowel rods, and on one of the tenons, and drive them in place. Then glue the remaining ends, and place the corresponding post in place. Drive this down to its place, and, after placing the shelf which supports the drip-pan, clamp this side together. Always use a block of wood to hammer upon. Never strike the frame directly.

Put the other parts of the stand together in a similar way. Allow the glue to dry over night before removing the clamps.

The shelf which supports the drip-pan may be fastened by driving two small nails through each post into it before the glue has had time to set. The nail-holes may be filled with a putty stained to match the finish by mixing some of the filler with it.

If the stand is to be a companion piece to the hall tree, the same finish may well be used. If not, then any desired finish may be applied, the kind of wood determining the manner of applying it.

The copper drip-pan can easily be made. Out a sheet of copper in the form of a circle, using a three and three-quarter-inch radius. If the copper must be bought, the gunsmith will probably cut it to shape.

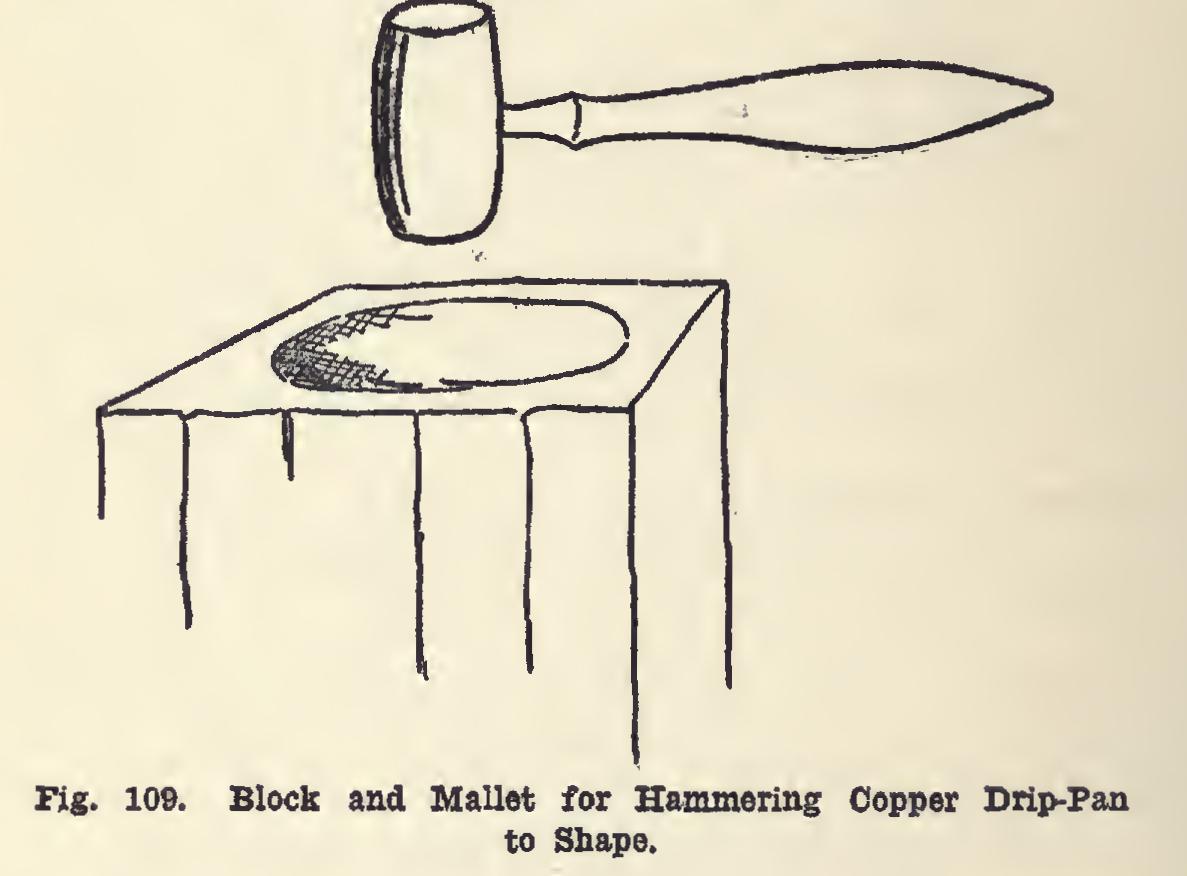

Prepare a block of wood (Fig. 109) so that it shall be three inches by three inches, with a length of six inches.

In one end of this, hammer a hollow about one-half an inch deep, having a diameter of about one and one-half inches.

Next, mark off the copper in a series of rings, using the center of the metal as the common center. Any radii will do, except that the largest circle should be made so as to be three quarters of an inch within the one forming the edge of the copper.

Procure or make a wooden mallet, rounding off one end of it so that it will fit the hole made in the end of the block; the other end should be flat.

Place the copper on the block; and, begin ning near the center, gradually turn the copper around so as to be able to beat over the hole with the round end of the mallet along the circles made on the copper. Work in this way along the circles until the outer one is reached; then work back toward the center, repeating until the copper is hollowed about an inch.

The copper will tend to "buckle" along the outer, edge. Turn the pan over, and, with the flat end of the mallet, beat it back to shape.

Tne copper may be polished and a coat of lacquer applied, or—better—it may be allowed to remain without any further attention.