Fittings for Windows and Transoms

sash, pulley, sashes, inches, type, fig and upper

FITTINGS FOR WINDOWS AND TRANSOMS The hardware for windows and sashes is not quite as extensive as that for doors, but is of about equal importance. Windows, unless care fully made and fitted, are likely to be a very weak point in building work. Sashes which bind or sag are bound to cause trouble; therefore the correct use of all possible means of preventing such occurrences should be attended to. A sash properly fitted at the start and balanced by the use of proper weights held by cords or chains running over well-made sash-pulleys is generally a success. These pulleys vary somewhat in de sign, from the ordinary rough cast-iron types which turn on a pin, up to the cold-rolled steel type with ball or roller bearings. Fig. 38 shows a sash-pulley of the ordinary type. The face of the pulley housing is usually of iron or steel, but may be made of bronze in some of the more expensive forms.

The face of the pulley housing is set in flush with the face of the pulley stile, thus setting the bearing center of the pulley wheel back into the weight-box. In order that the weight may hang properly from the cord or chain running over the pulley, the diameter of the pulley should not be less than 2 inches at the bottom of the groove in the pulley. This not only allows the weight to hang in a position in which it will not be scraping against the side of the weight-box, but also prevents the continual bending of the sash cord or chain over an arc of small radius, which is injurious to either cord or chain. Care should also be taken that the pulleys are smooth on all surfaces where the cord touches, and that they fit closely in their housings.

While braided cotton sash-cord is used for nearly all light windows, plate glass and heavy windows should be furnished with chains run ning over a special pulley having a square groove instead of the rounded one in general use. This allows the chain to fit the groove and prevents wear from a continuous effort to adjust itself to the pulley.

The ordinary sash weights are made of cast iron, and weigh from 3 to 20 lbs. They run from inches in diameter to 2 inches, and from inches in length to inches. When a

heavy weight is desired in a small space, lead weights are often used.

Many patented tape sash balances are on the market, and, when fitted to carefully weighed sashes, are guaranteed by the manufacturers for a considerable term of years.

The effort expended in lifting a properly balanced sash is not great, yet some device which can be gripped quickly and securely is desired. Fig. 39 shows a small sash-lift which is satisfac tory for light windows. This lift is made in all metals and finishes from cast iron to solid bronze. If a flush lift is desired, Fig. 40 shows a good type.

In case of heavy sash, the lift shown in Fig. 41 is commonly used. Two of these handles are often fastened to the under side of the bottom rail of the upper sash for use in pulling down large upper sashes. Another device which can be used for this same purpose consists of a small metal socket inserted in the top rail of the upper sash. A metal hook fastened on the end of a pole is placed in the socket when it is desired to pull down the sash.

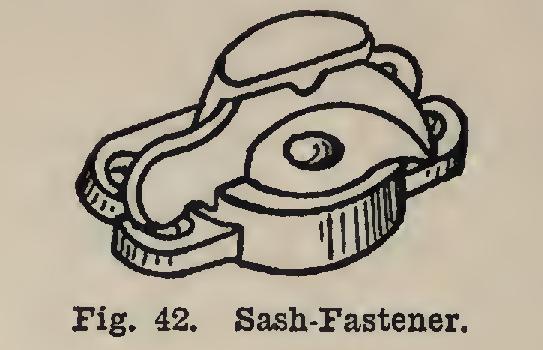

In choosing a form of the two points which should be considered are its capaci ties for protection and for the drawing together of the upper and lower sashes. From the pro tective side, it should not only be of substantial build, but should be constructed so that it can not be worked by inserting an instrument through the crack between the upper and lower sash. In fact, there are few if any of the sash fasteners which are used to draw together the two sashes which will resist any great pressure applied from the outside. Their design on the principle of the lever pivoted on one sash is a point of weakness.

The type of fastener shown in Fig. 42 is con sidered to fulfil the requirement of drawing the two sashes closely together to prevent rattling and leakage of air, and, if secured by substantial screws, is probably as safe as any of this type of fastener. The cam action shown also forces both top and bottom sashes to a close fit in the window-frame at top and bottom.