Girders

floor, girder and beams

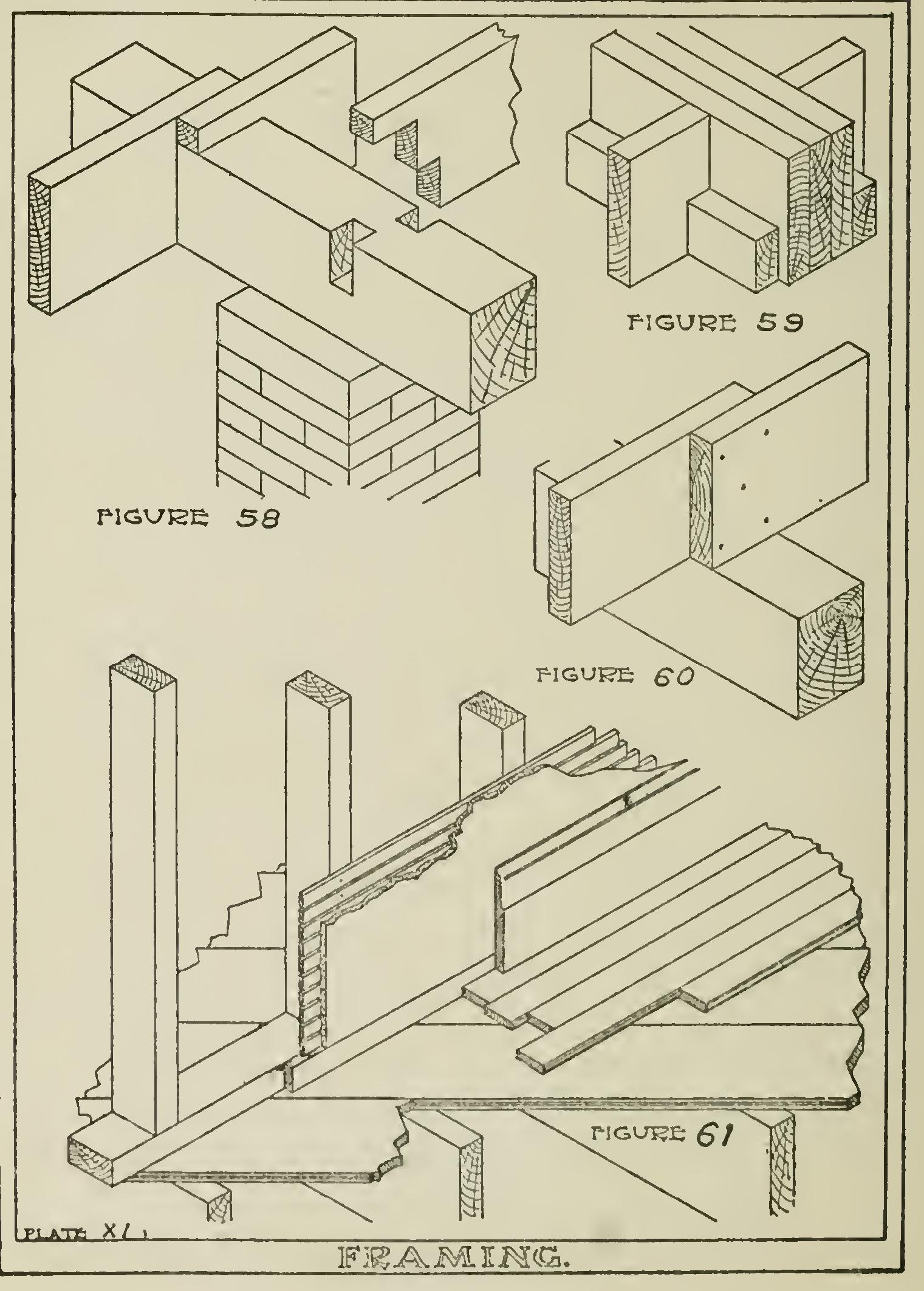

GIRDERS Fig. 58 illustrates a cellar girder of six-inch by eight-inch yellow pine supported on a twelve-inch by twelve inch brick pier with Bluestone cap. The floor beams are let into girder to a depth of four inches. The top two inches of beam rests on top of girder, thus making the under side of girder flush with the under side of floor beam.

Fig. 59 illustrates another flush girder fre quently employed though not as good as preceding example. It consists of a girder composed of three of the floor beams well spiked together, with two inch by four-inch strips well spiked on to support floor beams which are notched over them.

Fig. 60 shows an ordinary girder with beams resting on top. Beams should be lapped over girder and spiked together as shown.

Fig. 61 illustrates the construction of an interior partition running at right angles to the direction of the floor beams. A rough flooring, usually of seven-eighths-inch by eight-inch matched spruce or hemlock, is laid diagonally over floor beams and well nailed to them. On top of this floor, the par

tition is erected by putting down a two-inch by four-inch partition sill or shoe and then raising the studs, which are usually of two-inch by four-inch stuff set sixteen inches on centers. A seven eighths-inch by two-inch ground is nailed at the floor angle to serve as a gauge for lath and plaster and as a nailing for base. The finished floor is shown extending under the base and is generally of seven-eighths-inch stuff, matched, and not over three inches wide. A layer of deafening paper should be put between rough and finished floors. Boards should be blind nailed to every bearing and laid with end joints broken. Partitions are frequently made sound proof by filling in between studding with brick, as in the case of a frame partition between any living room and a kitchen, laundry or other room where there is any noise.