Joints Used in Framing

fig, tenon, joint and shown

JOINTS USED IN FRAMING Plate IX illustrates and shows the application of the principal joints used in framing. Starting with the main sill, Fig. 44, the method of jointing at the corners is shown; the joint being known as angle halving. The corner post and studs are mortised into sill. This is done in the best work, the common way being to cut off posts and studs with square ends, and spike to sill and girt. The beams are shown let into the sill.

Fig. 45 illustrates tee halving, as in the case of wall plates coming together at right angles.

Fig. 46 illustrates beveled halving. This joint is used in splicing plates and sills.

Fig. 47 illustrates dovetailed halving.

Fig. 48 shows the girt framed into corner post with a mortise and tenon joint, pinned with hard wood pins or well spiked Fig. 49 shows the girt framed into corner post with a dovetailed tenon joint. The girt is secured firmly in place by driving the wedge shown.

Fig. 50 shows an isometric view of the dove tailed tenon joint.

Framing Around a Fireplace

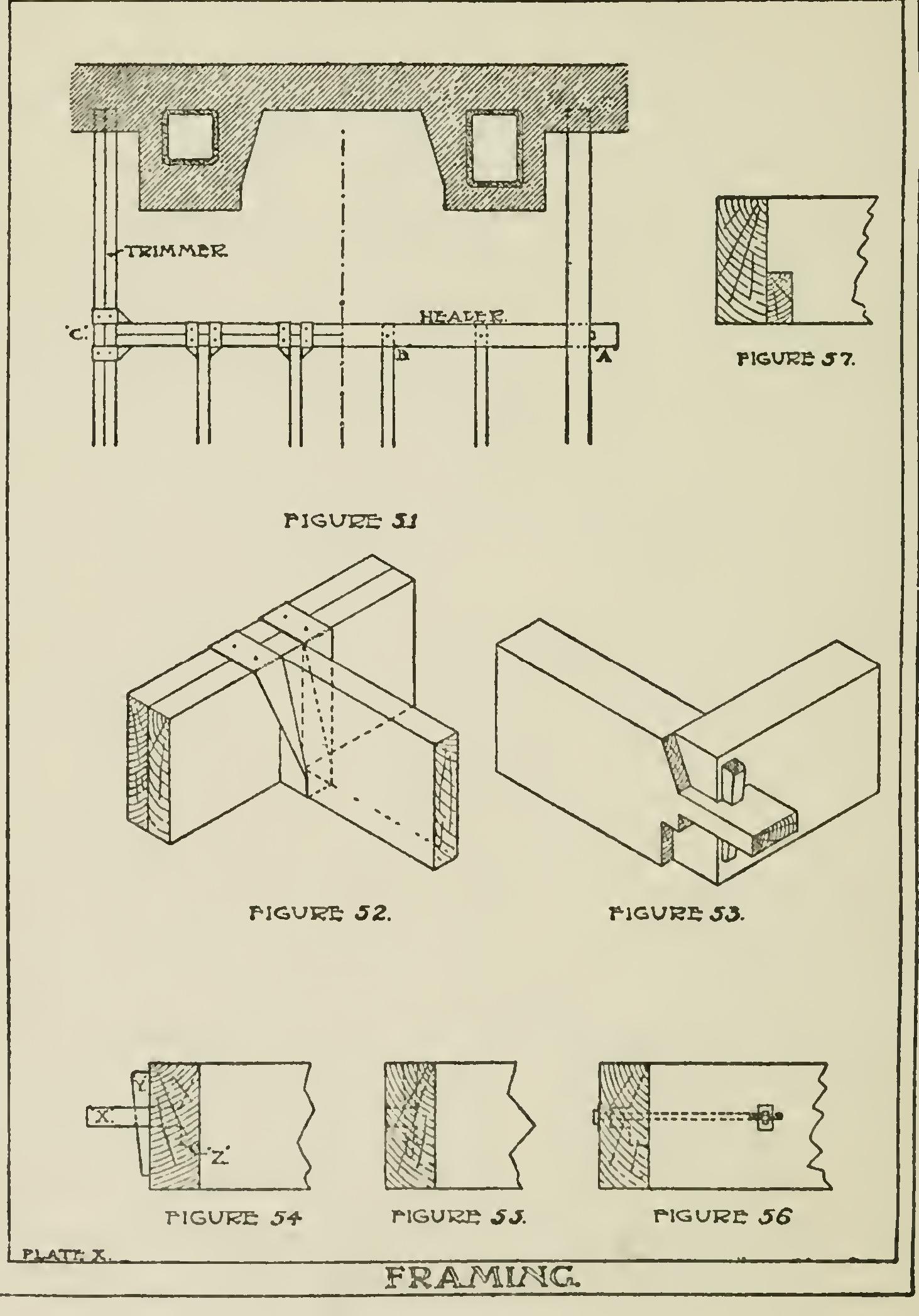

Plate X illustrates the use of the tusk and tenon joint and the wrought iron joist hanger in fireplace framing.

One-half of Fig. 51 shows the header, trimmers, and tail beams framed together with the tusk and tenon joint, which is considered the best joint, both theoretically and practically; and the other half of the plan shows the use of the wrought iron hanger, which is used when it is important to pre serve the entire strength of the timbers.

Fig. 52 illustrates the use of hanger to support tail beam.

Fig. 53 is an isometric view showing construc tion of the tusk and tenon joint. This joint is also shown in Fig. 54. The thickness of the tenon "X" is one-sixth the depth of the beam, and the tenon is so fixed that it has its lowest surface in the center of the depth of the beam. "Z" is the tusk which bears weight of the header and is let into the trim mer about one and one-half inches and secured in place by means of the hardwood wedge, "Y." The projection of the tenon beyond the surface of the beam, as well as the wedge, are omitted when they would be in the way. This construction is illustrated in Fig. 55, which shows the tenon se cured with a hardwood pin through the center of the header; and is also shown in Fig. 56, where it is secured in place by means of a three-quarter inch bolt. A hole is cut in the beam as shown, to receive the nut, and is made large enough so that nut may be turned.

Fig. 57 shows a cheaper method of framing' which is used to a considerable extent, though not with as satisfactory results as the previous ex amples. The tail beam is supported on a "two by four" joist, spiked to the header.