Arches and Lintels for Fireproof Work

concrete, breeze, coke, wood, lintel, construction, iron and blocks

ARCHES AND LINTELS FOR FIREPROOF WORK.

The consideration of relieving arches—or, as they are often termed, discharging arches—over a wooden lintel, naturally brings up a very im portant question. In these days of fireproof construction, when wood is being eliminated from the structural parts of buildings wherever possible, wooden lintels are not used in the best practice. Instead of wood, iron I-beams and artificial stone lintels are now largely employed in the best class of work. But both of these have one defect—namely, that, from their nature, it is impossible to nail grounds or other wooden finish to them. As the chief purpose of a lintel is, of course, to form a square head for a window or door-frame, this consideration is important.

One of the best methods suggested for over coming this little difficulty—and not only sug gested, but widely used in some parts of Europe—is to form the lintel of coke breeze con crete. Breeze is the English term for the small cinders left from the fires used for burning bricks in a kiln, or from the manufacture of coke in gas ovens. Mixed with cement, it makes a concrete that is fireproof and that possesses another useful quality in that nails may be driven into it with ease. This last property has led to the use of coke breeze in a variety of places where wood was formerly employed.

For instance, thirty or forty years ago it was still common to find bond timbers inserted in brick and stone walls at such heights as would render them convenient for fixing the trimmings and finishing woodwork to afterwards. These bond timbers were certain to shrink and were also very liable to rot; and, as either of these contingencies made them a source of possible weakness to the wall, their use was gradually discontinued, until it has ceased altogether.

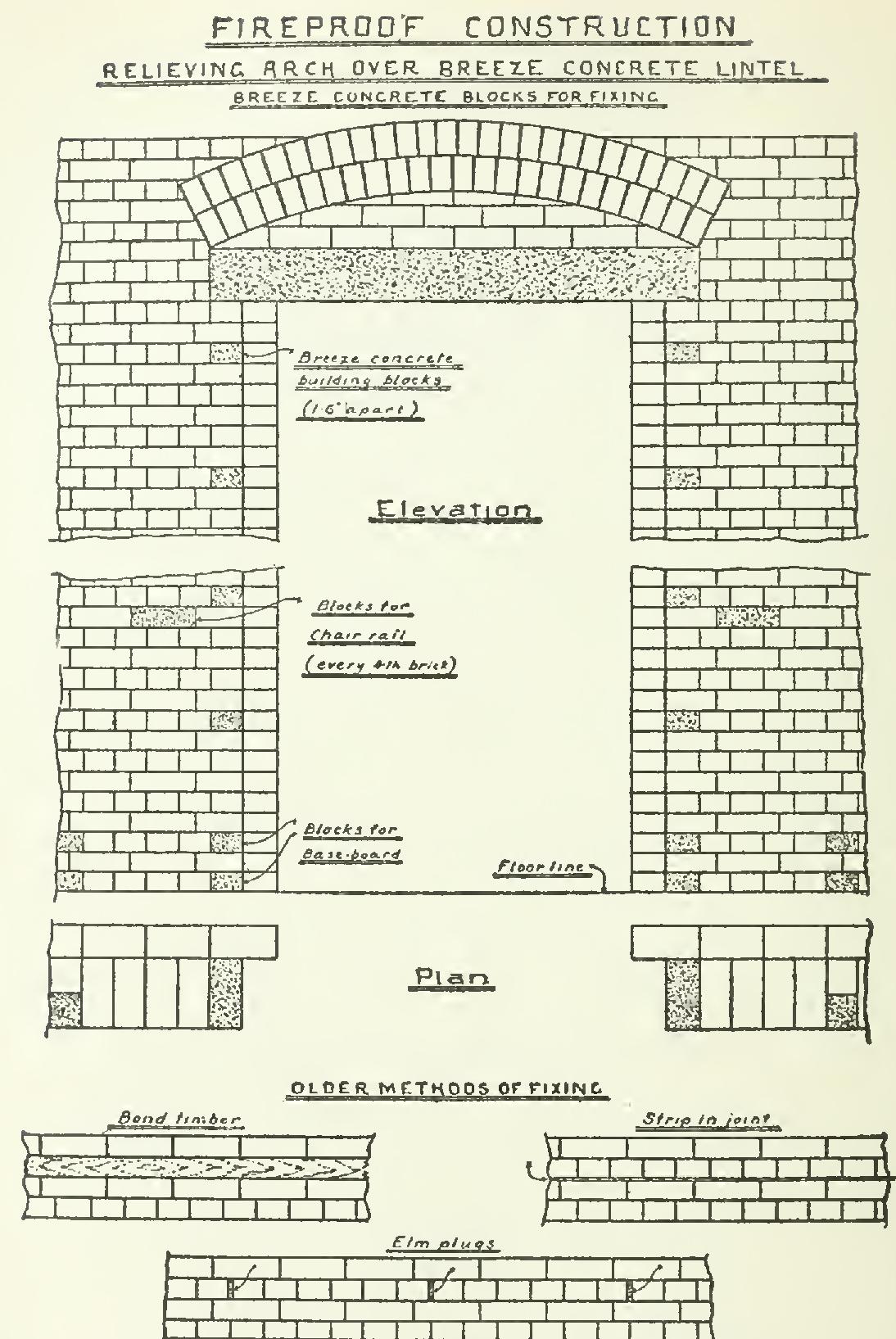

The substitute at first proposed for the bond timbers, and largely used for many years, was a thin strip of wood built into a joint of the masonry or brickwork, thus reducing the possi bility of failure from shrinkage. The strips were, however, in a great measure open to the same objections as the larger bond timbers, and many architects refused to allow them to be used. Instead, they specified that hardwood Fig. 114. Details of Fireproof Brick Construction.

(usually elm, on account of its non-liability to split) plugs or wedges should be driven into the joints at intervals, after the walls had set, the grounds or other woodwork being nailed to these plugs.

The invention of coke breeze concrete has, however, made it possible to substitute bricks and blocks made of it, which can be built into the wall during construction. They neither

shrink nor rot, while their property of taking nails readily makes them ideal for the purpose of fixing woodwork.

Fig. 114 shows the application of coke breeze in the lintel and fixing blocks around a revealed opening for a doorway in a 12-inch wall. The blocks are also shown at each side, where they would be continued to form a fixing for the grounds for the chair rail and These blocks should be of the size of the bricks used in the building, and may, of course, be readily moulded in any suitable machine. Long before the use of machines for this purpose, however, many hundreds of such bricks were made in the roughest of wooden moulds improvised for the purpose. As coke slack or breeze is very often merely a nuisance to the gas manufacturer, its cost is next to nothing in many instances.

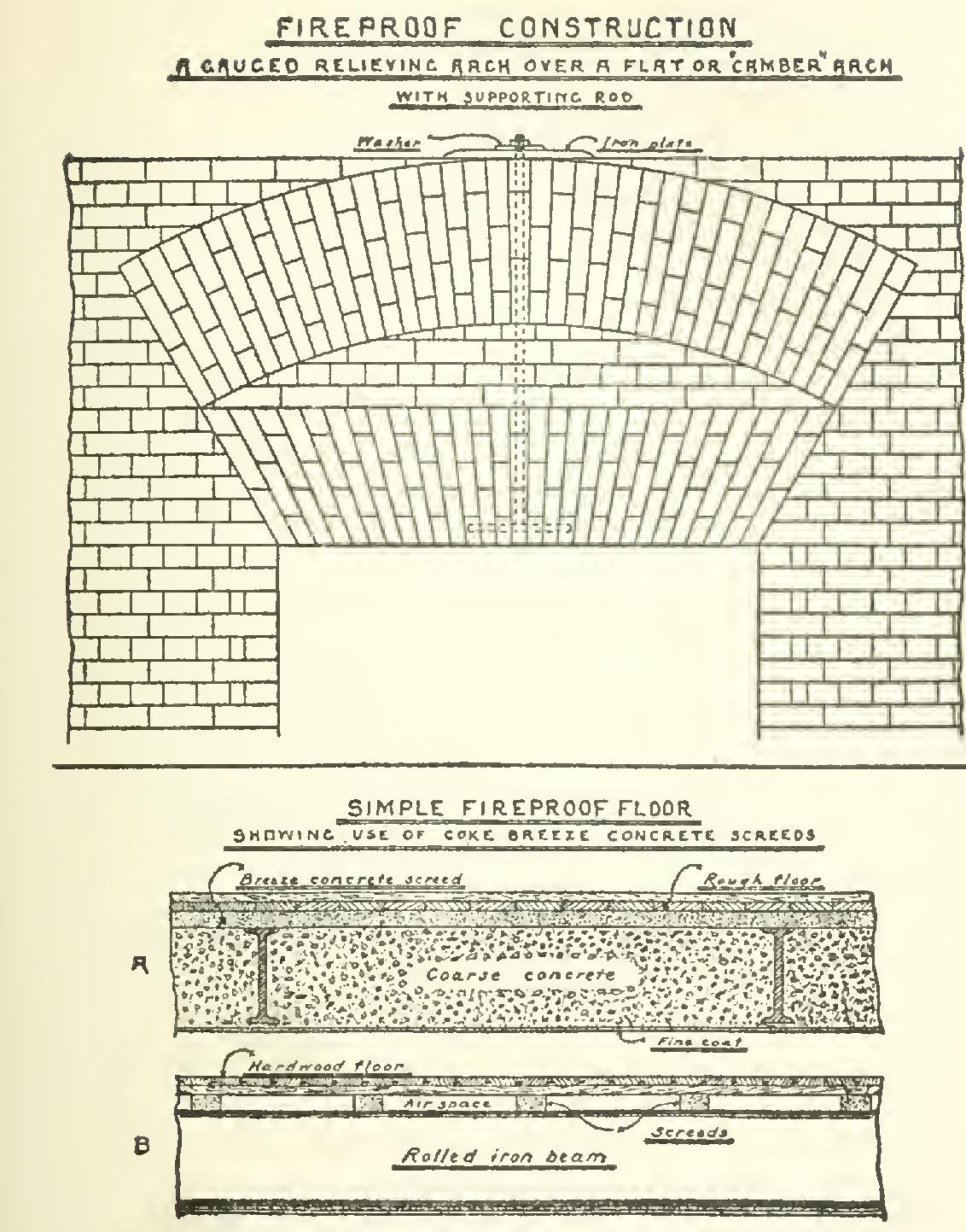

Fireproof Floors. The question of fireproof construction is by no means a new one, although the builders of the present generation have probably seen more attention devoted to it than did their predecessors. As showing an inter esting method of dealing with the lintel prob lem, the upper portion of Fig. 115 is worthy of attention. A flat or camber arch takes the place of the wooden lintel, and is supported by means of an iron rod from the crown of the relieving arch above. For first-class work it would be hard to surpass this scheme, but its cost would prevent its adoption in anything but the very best practice.

While on the subject of fireproofing, another useful application of coke breeze concrete may be given. The many forms of iron and concrete fireproof floors are, in the majority of cases, covered with wood blocks or battens for the sur face. Wood block floors are usually laid right on the concrete of the fireproof construction, some pitch or tar compound being used as a bed ding cement. When batten floors are used, however, strips of quartering are usually laid on, or imbedded in the concrete, and the battens nailed to them. Many first-class architects, on the other hand, do not care for this method, and prefer that breeze concrete screeds should be laid in place of the quartering. If the screeds are run when the concrete below is still damp, they become an integral part of the body of the floor, and make a sounder job altogether.

The lower portion of Fig. 115 shows a simple rolled iron beam and concrete floor of the type generally known as "Dennett's," with board floor over. A shows a cross-section through the iron beams; and B, a cross-section through the concrete screeds, the boards being nailed to these as suggested.

Fig. 115. Details of Fireproof Construction.