Barns

fig, frame, timbers, plank and roof

BARNS With the scarcity of heavy timbers and con sequent cost, it is time carpenters who are to erect barns should give some study to the newer methods of framing, where timber is from 6 to 12 inches wide, and none thicker than 2 inches. The use of modern hay and grain elevating machinery, calls for barns with open centers; hence upper cross-ties, collar beams, etc., are in the way, and they are quite unnecessary.

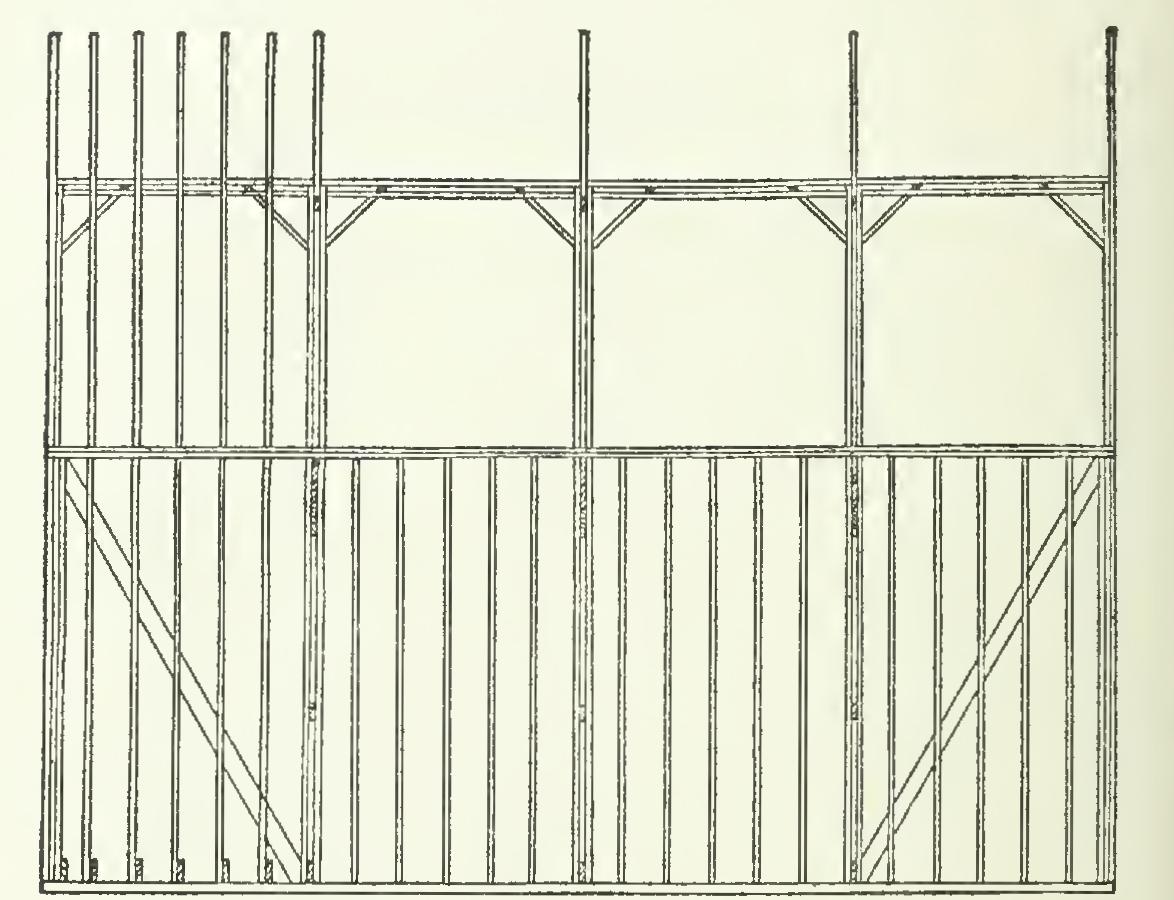

A plank frame of size and construction indi Fig. 132. Wind Bracing for Plank-Frame Barn.

sated in Figs. 131, 132, and 133, is in every way satisfactory, and is fully as strong as an old fashioned frame made of timbers 8 to 12 inches square. It is about two-thirds as costly; and less experienced carpenters are required to erect it.

In this plank frame, there are no timbers larger than 2 by 12 inches, which are doubled and trebled where great strength is required. Where tensile strength is required, two 2 by fl inch are nearly as good as an 8 by 8-inch tenoned and fastened in the old-fashioned way with a Fig. 133. Side Wall Plank Framing.

pin. In this frame there are no tenons, all members being put together with spikes.

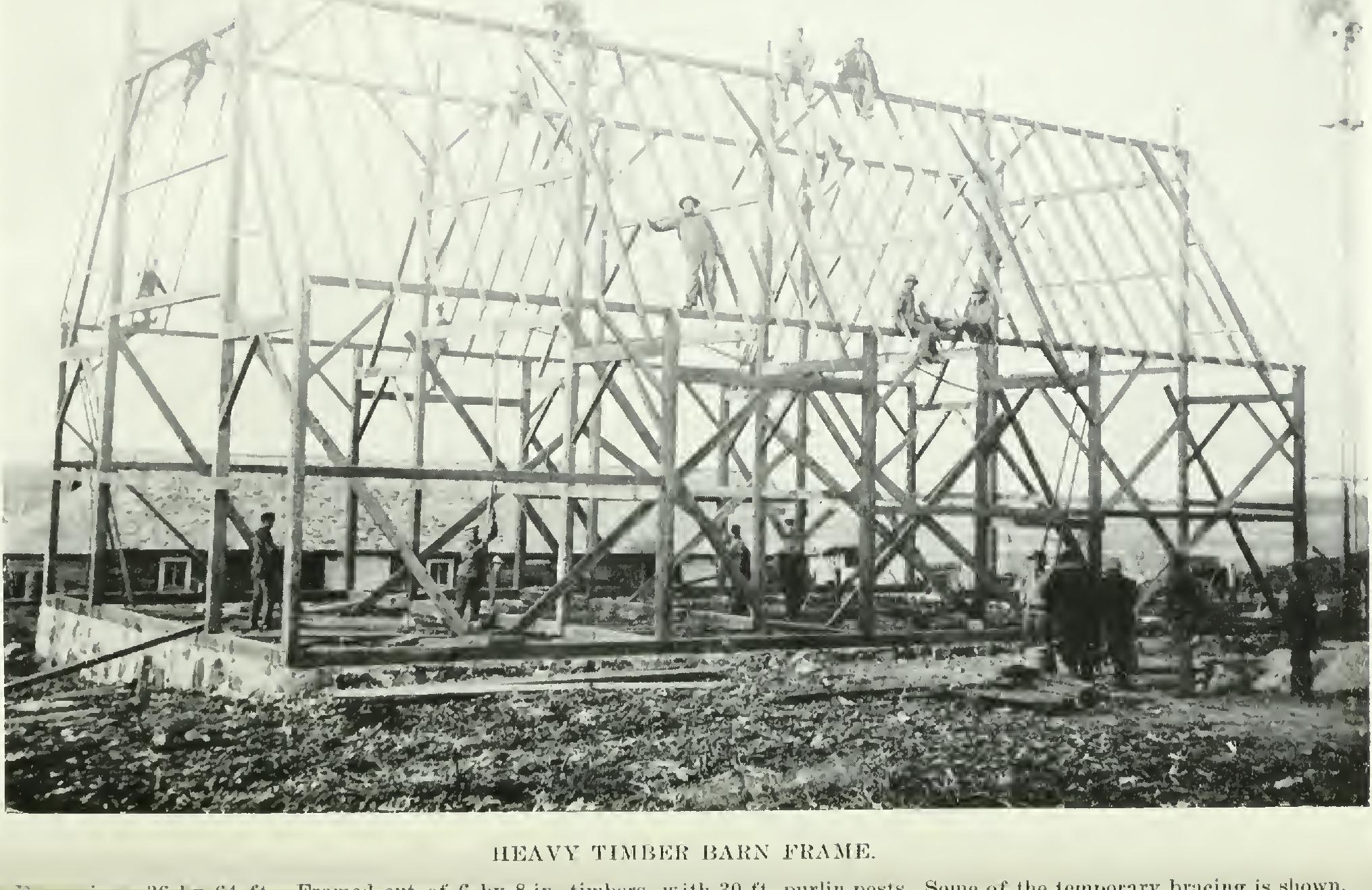

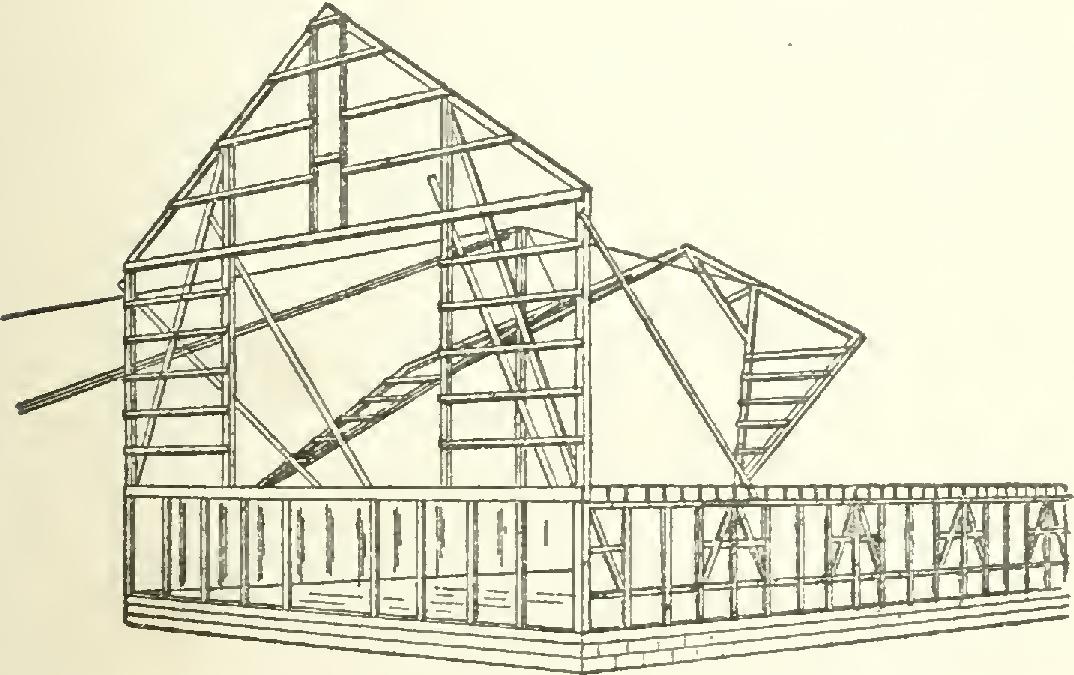

Fig. 134 shows the method of raising or erecting the bents after they are framed.

The posts for this barn are 20 feet high, and are built up of joist spiked and bolted together. The bracing and cross-pieces were framed to gether in sections before raising to their posi lion. The inner set of posts, set raking, extend up to form the purlin. The rafters, of which there are two sets, are placed on two-foot cen ters, lapping at this point.

This kind of construction is very popular in some sections of the country, and, when well built, makes a very substantial job. The tim bers, being entirely of joist, are such as can be readily obtained from any lumber yard that is worthy of the name. This is a thing in itself

that should not be overlooked, as solid framing timbers are not so plentiful as in years gone by, and in many places are not carried in stock.

Fig. 134. How the Bents are Raised.

The dealer places the order after he receives the contract to furnish the lumber; and this means that the contractor must wait for the lumber to be shipped from some distant mill, and more than likely to be first cut from the round tim bers; and when it does finally arrive on the building site, it is yet green and really not fit to frame for the best results.

Another thing in favor of the plank frame is that the timbers are light and more easily put together than by the mortise-and-tenon method.

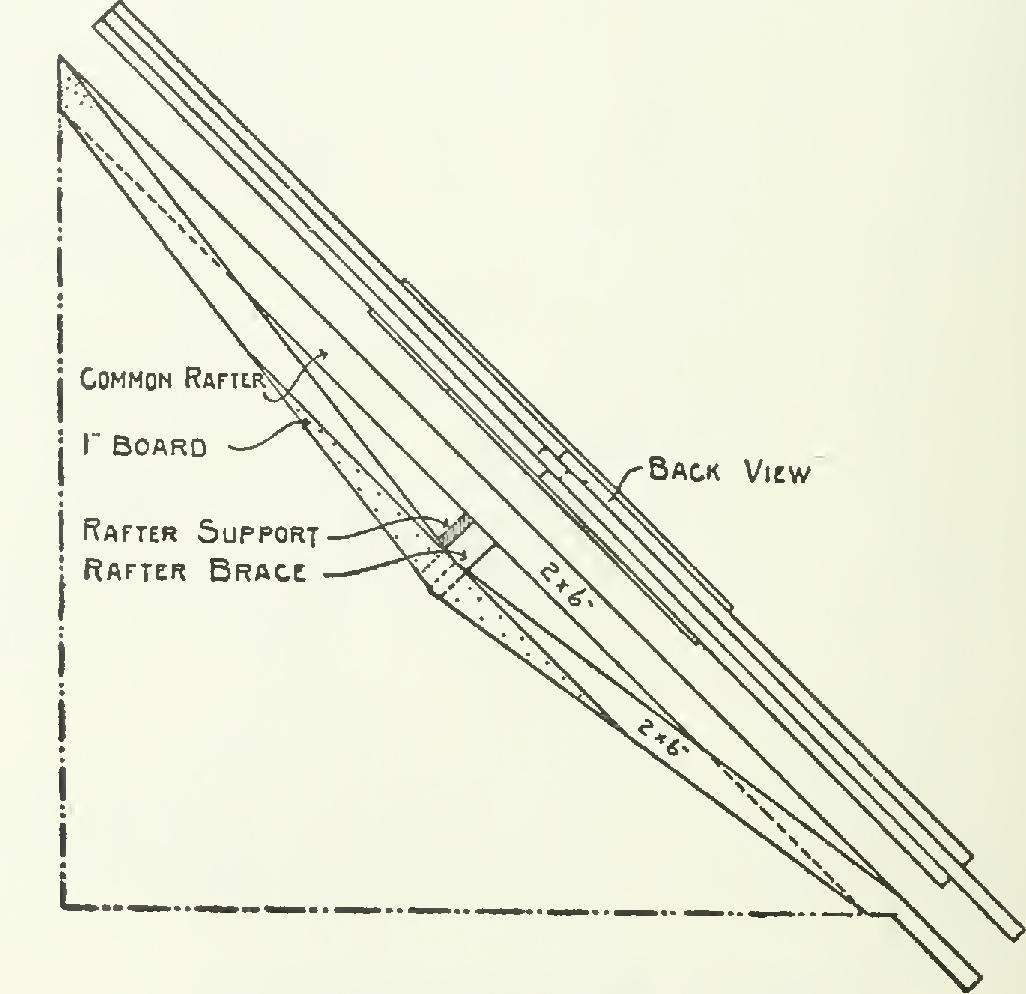

Fig. 135. Queen Rafter for Roof Support.

Roof Supports. Fig. 135 is a sketch of what is called a queen rafter. It is used for barns up to 34 feet wide, without putting in purlins.

While it possesses considerable merit for stiff ening the roof, there is nothing in it to keep the sides of the building from spreading, as it does not form a tie, which is necessary when the loft floor is far below the plate.

To secure the additional strength needed, the rafters should be set on 24-inch centers, and Fig. 136. Plank-Framed Truss for Gambrel Roof.

sheathing put on diagonally toward the center, close and well nailed. The center rafters where the sheathing meet should be doubled and well spiked together. The floor-joist lap onto each stud, and should be well nailed to prevent spreading.