Constructing a Cupboard

shingles, shingling, buildings, corner, boards and square

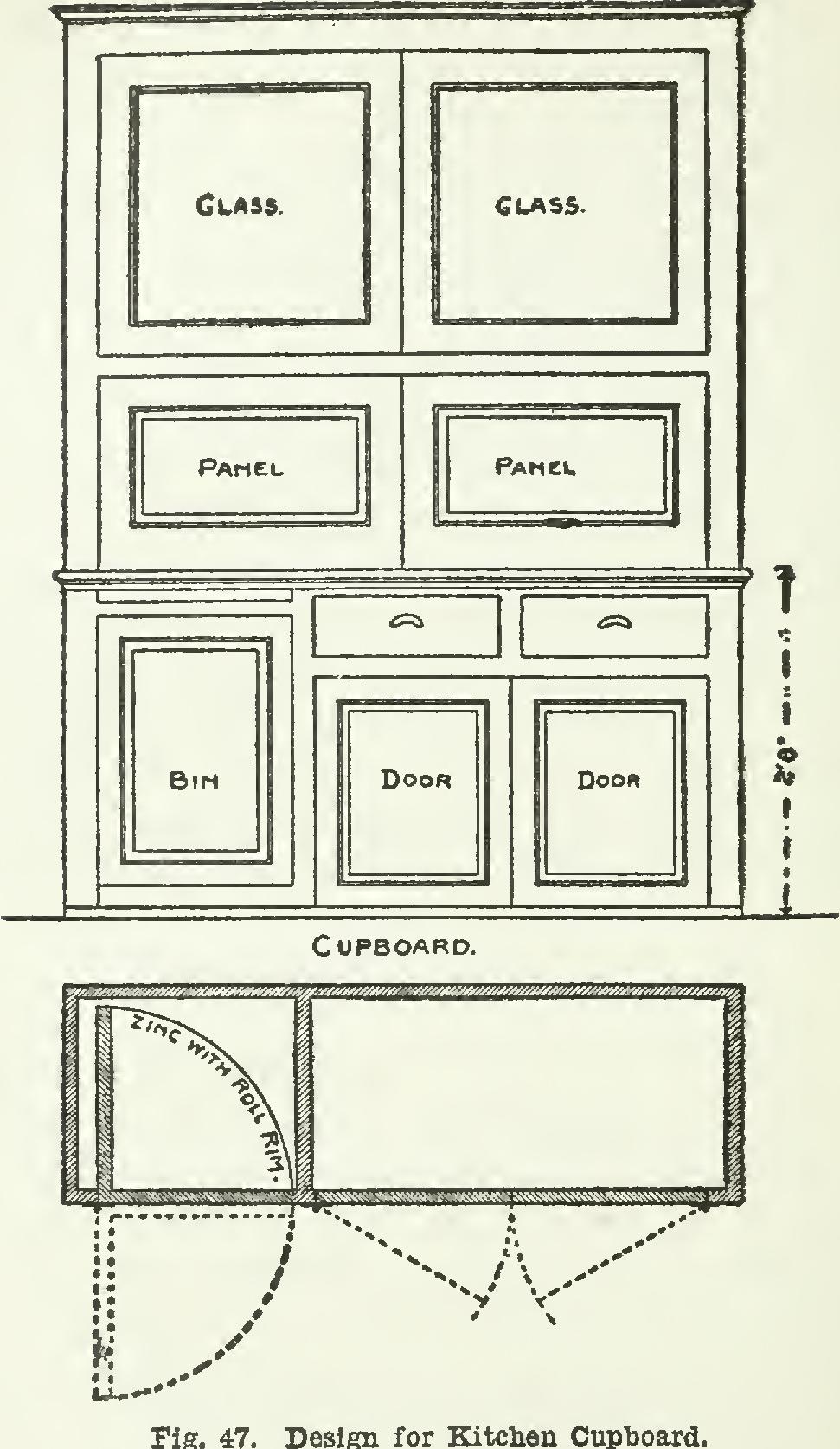

CONSTRUCTING A CUPBOARD Fig. 47 is a sketch of a cupboard. It makes a very complete fixture for the kitchen, and is easily made. The flour bin is hung the same as a door, and swings outward as shown by the dotted lines in the plan. It is quarter-circle in shape, the back being made of zinc, with a roll rim at upper edge. A board inches thick and 16 or 18 inches wide is used for the front and back. The bottom is grooved in about inches from the bottom ends of these pieces, and gained in about % inch deep. The front and back edges are grooved about % inch wide by 1/4 inch deep, to receive the zinc back, which is made fast by nailing with round-headed tacks. The front may be paneled, as shown in the draw ing, if a better finish is desired.

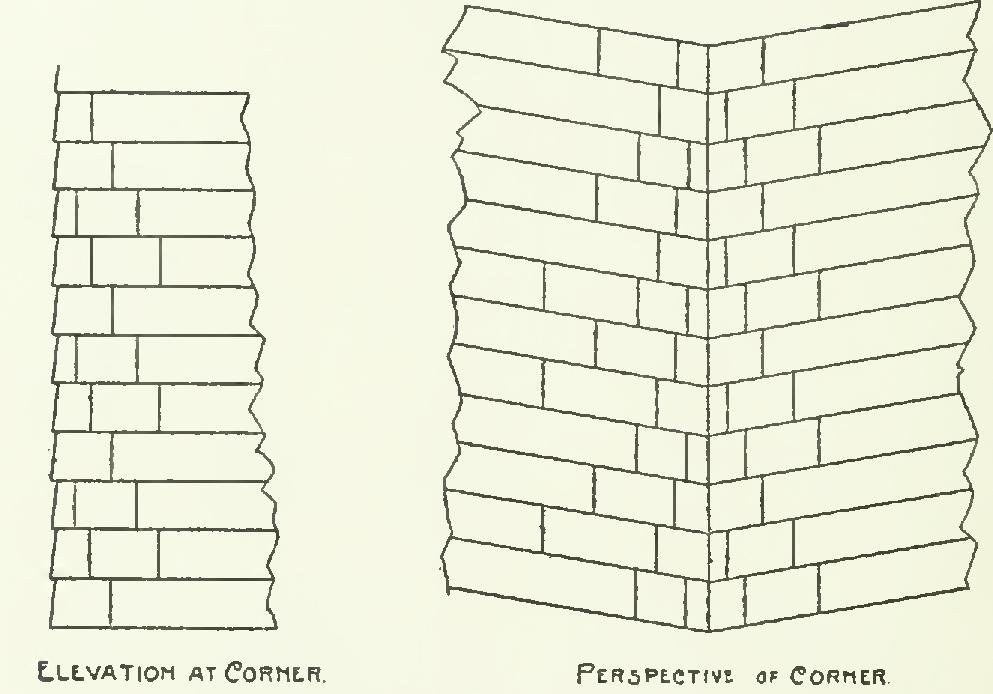

Shingling the Sides of a Building It is the style in many sections of the coun try, to shingle the sides of buildings, not only for the smaller class of buildings, but for public buildings as well. See Figs. 48, 49, and 50.

When properly done, it makes a good-look ing building, and the cost is generally less than for any other siding material, since wall shingles can be put on with more space exposed than in regular roof work; also a cheaper grade of shingles can be used for this purpose, with good satisfaction. One thousand will cover about 150 square feet of steface; and a man will put on about as many in a day as he can on the ordinary roof in the same length of time. As this kind of work is comparatively new, differ ing in some respects from roof shingling, it may be that some will be benefited by a few pointers concerning the work.

The building may have corner boards and water-table, though these are generally omitted. It makes a more weatherproof and at the same time a better-looking job, to run the shingles out to the corners. The first course at the bot tom should be double. The first or under course furnishes a good place to work in some of the poorer shingles. In shingling the corners, the shingles on one side should be kept flush with the corner, and those on the other side should be flush with the butts or a little beyond, so that they may be trimmed even by sawing in on the edge and cutting out with a knife.

There are several ways of getting the first course straight; a straight edge can be used by tacking a shingle at each end to hold it in place, and should be used for each course thereafter.

Fig. 48. Shingling a Corner.

The siding boards should be straight and level, and the first course should extend a little below to form a water drip. The courses should come even with the top and bottom of the window frames, which can be easily done by varying the courses the same as in clapboard siding. It will be necessary to cut the tops of the two last courses under the windows, but the pieces can be used at the tops of the windows, which should have a rabbeted cap. The shingles should be doubled at the point; one row should be put above the cap, and the other should drop below these. At the corners of the window-frames, it is better to cut out a corner of a few shingles so as to break joints.

When a first-class job is desired, it is better to put the cornice on and cut the shingles to fit under it. For some classes of buildings, it is all right to put the cor nice on over the shin gles; or, in case the cor nice is already on, to drive the shingles up under it.

Do not use too large nails for shingling. If the boards are sound, three-penny nails are. large enough.

Paper may be put under the shingles, and in some cases this is the best method; but as so many nails are driven through the paper, it seems better to put it on the inside of the sheathing between the studs.

As to the cost of this method of building, boards for less than $20.00 per thousand may be used, which will answer. The shingles at $4.00 per thousand will come to about two cents per square foot laid. Plaster will cost about one cent per square foot, so that five cents per square foot will cover the cost.