Framing for Cement Plaster Houses

lath, center and strips

FRAMING FOR CEMENT PLASTER HOUSES. The construction of the frame for a cement exterior differs but slightly from that for wood siding. Usually the sheathing is put on the outside of the studs (see Fig. 90). Upon this is tacked tar building paper. The furring comes next. The strips are 1/2 by 21/4, by 2, or by inches, and are nailed vertically. They are spaced twelve inches from center to center for the lath, irrespective of the position of the studding. The thicker furring is used when more air space is desired than can be obtained with the thinner strips.

That there may be plenty of clinches for the plaster, the wood lath are but one inch wide. They are the usual length, however, and the furring strips are spaced one foot from center to center, just as for metal lath. Fig. 91 gives sectional views of a plain plastered wall and of a half-timbered wall, showing details of con struction.

Window and Door Frames.

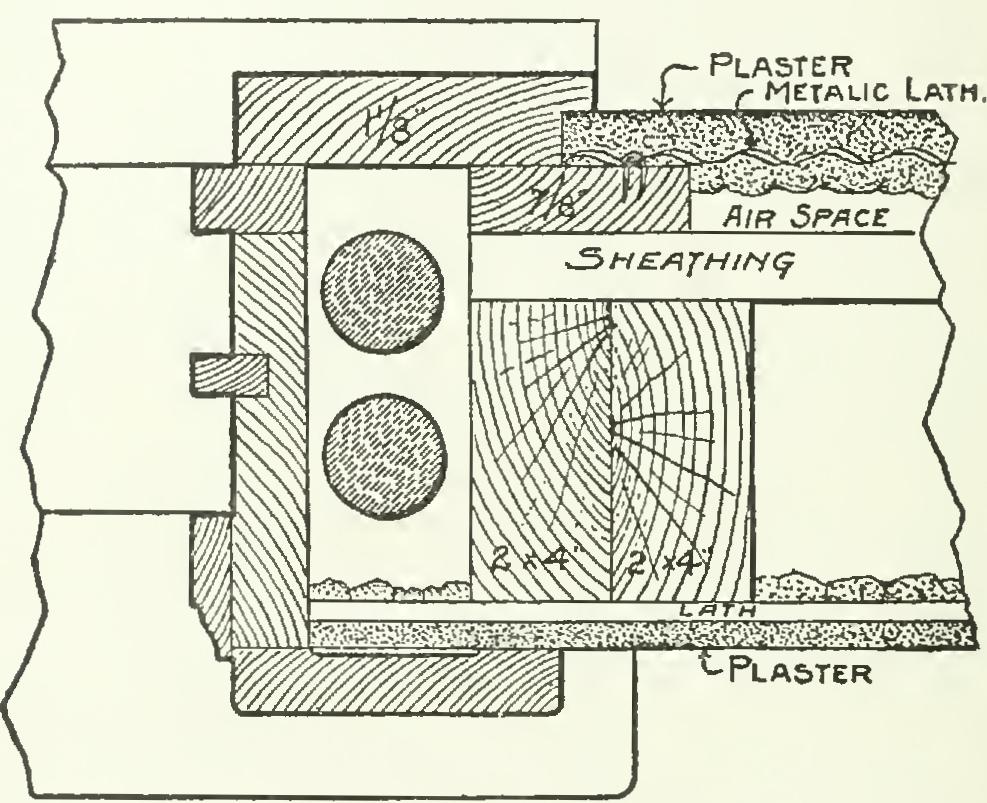

Window framing for cement plaster houses should be set as de I tailed in Fig. 92, which shows the use ofexpanded metal lath secured to strips. This gives a better clinch for the mortar than if the lath were stapled directly to the sheathing; besides, it creates an air space and provides a wider jamb at the windows, which is essential where large plate glass is used, necessitating heavier sash than for the common double strength glass. It is a good idea to plow or groove out the corner of the frame so that the mortar will extend under the edge of the frame. The flashing of the caps may be put on in the usual way, and plastered over. Of course it would be much easier, so far as the plastering is concerned, to set the frames after the plastering is done; but this would not make so tight a job, especially as to the prevention of leakage at the top. The framework should be very substan tial; otherwise settlement or vibration will crack the plastering.

Fig. 92. Framing for Windows, Cement Plaster Rouse.