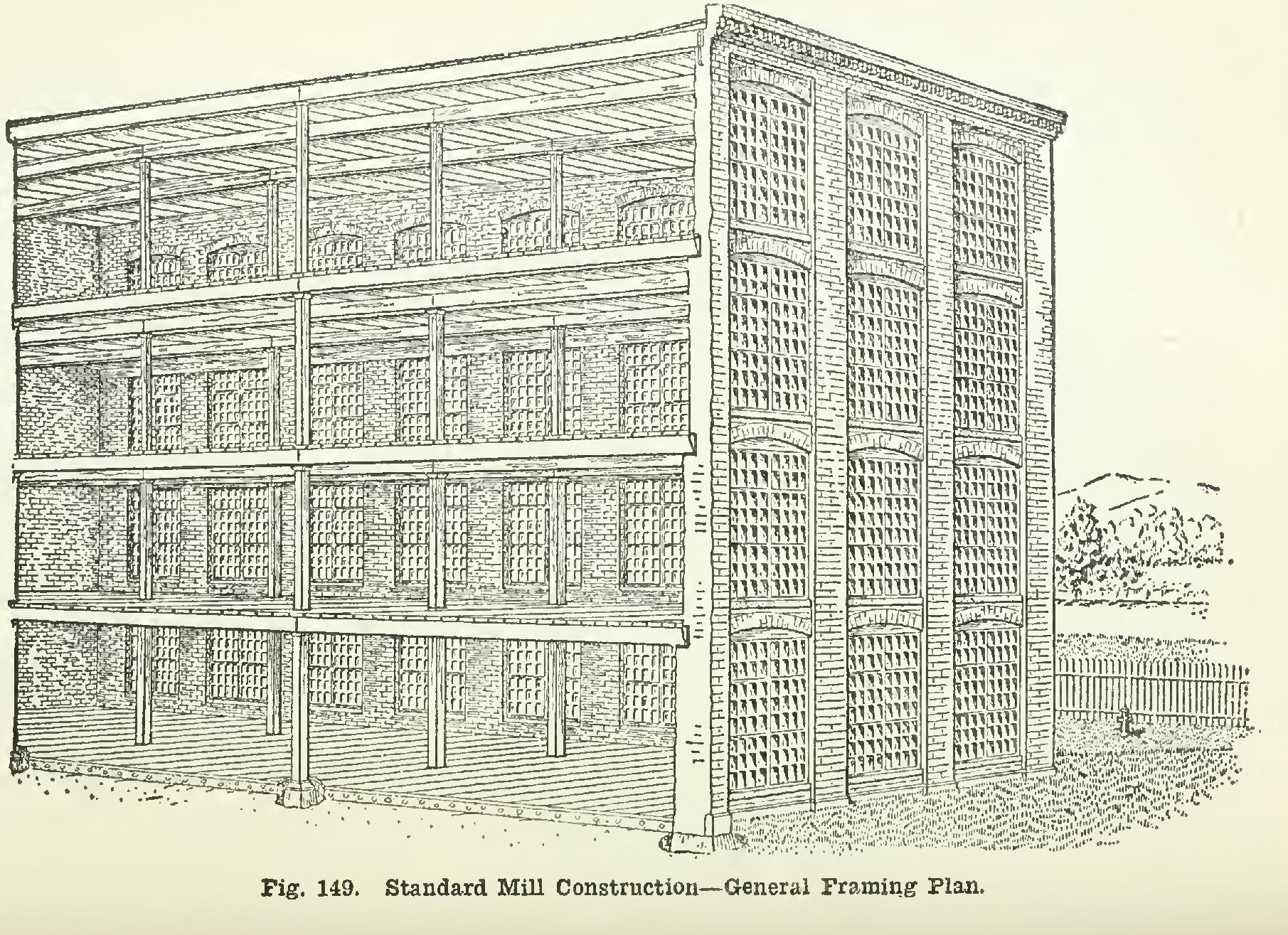

Standard Mill Construction

light, roof, floor, walls, increasing, saw-tooth, wide and beams

Beam boxes are of value, as they strengthen the walls when floor loads are heavy and dis tance between windows small; they facilitate the laying of the brick and the handling of the beams; and there is less possibility of breaking away the brick in put ting the beams in place.

They also insure a proper air-space around beams.

Columns should be set on pintles, which may be cast in one piece with the cap, or separately, as pre ferred (see Figs. 156 and 157.) Col umns of cast-iron are preferred by some engineers; and, when the building is equip ped with automatic sprinklers, have proved satisfactory, but are not so fire resisting as timber. Wrought-iron or steel col umns should not be used unless encased with at least 2 inches of fireproofing.

One of the most important features of slow burning construction is to make each and every floor continuous from wall to wall, avoiding holes for belts, stairways, or elevators, to the utmost extent possible, so that a fire may be confined to the floor where it starts. No well informed mill owner, engineer, or builder will therefore fail to locate elevators, stairs, as well as main belts, in brick towers or in sections of a building cut off by incombustible walls from all the rooms of a factory. Openings in these walls should be provided with fire-doors, preferably self-closing. These should be hung on heavy, inclined, solid steel rails at least inches by inch, and balanced by a weight held by a fusible link.

In modern practice all belts and ropes which may be used for transmission of power to the various rooms are placed in incombustible ver tical belt-chambers, from which the power is transmitted by shafts through the walls into the several rooms of the factory. There should be no unprotected or unguarded openings in the inner walls of this belt-chamber.

Saw-Tooth Roof Construction. The great ad vantages and the increasing use of saw-tooth roof construction, together with the lack of fa miliarity with it in many sections, make it desir able to outline its important features.

Two typical designs are illustrated—one, Fig. 158, a textile weave shed with good basement for shafting for driving looms on main floor above, thus dispensing with the overhead shaft ing and belting in the weave room; the other, Fig. 159, a design for a light machine shop or foundry. Other designs are applicable, with light wooden trusses or reinforced concrete.

The important advantages of this form of roof construction are: Uniform diffusion of light throughout the room, thus making all space in it available. all interior surfaces painted white, and with ribbed glass in the sash, the diffusion of light is almost perfect.

Adaptability for lighting large floor areas in wide buildings with low head room, compared with what is necessary in wide buildings with the ordinary form of monitor skylights.

They provide the true solution to the prob lem of excluding the direct rays of the sun and obtaining the very desirable north light in all sections.

Economy in lighting, in that they lessen the fixed charges due to the lessened number of hours per day during which artificial light is necessary.

Better working conditions, especially in tex tile mills, therefore increasing production and encouraging permanency of the help.

The saw-tooth form is especially adapted to buildings for weaving and similar processes iu textile factories, machine shops, foundries doing light work, and for similar or allied opera tions, such as assembling and drafting; and in some dye houses, where careful matching of colors is necessary.

As to the disadvantages, while testimony of those having had experience with saw-tooth roofs is almost uniformly favorable, more or less difficulty has been experienced. Practically all of it, however, may be summed up as due either to faulty design or to poor workmanship. The difficulties in general are caused by leaks due to severe conditions during winter in our northern climate, poor ventilation, excessive heat when roofs are thin, or excessive condensa tion on under side of roof and glass when the temperature outside is low and there is consid erable moisture in the rooms.

It may here be well to state that the light roof of 2-inch and 3-inch joists and boards should never be used; and that, while the prin ciples of slow-burning or mill construction, with the heavy timbers, are preferred, the increasing difficulty of promptly obtaining yellow pine lum ber of good dimensions, and its increasing cost, often necessitate the use of trussed forms, using rather light timbers. In no case, however, should they be less than 6 inches in width, and of depth sufficient to carry the load—this in order that they may be slow-burning. The roof in all cases should be of plank, with wide bays.