Standard Mill Construction

floor, floors, plank, laid, timbers, fire, top and inches

STANDARD MILL CONSTRUCTION The succession of heavy fire losses each year is the penalty which this country is paying for the erection of light, cheap, and poorly designed buildings. The cost of fire insurance is a direct yearly tax on the building and its occupants. It is the duty of those responsible for the design of buildings, to plan them so that this tax may be the smallest possible, and this can be done often without any great increase in the cost of the building itself.

According to tests made by the Boston Insur ance Engineering Experiment Station—which only confirm and bear out the experience of years—it has been clearly shown that, all things considered, the mill or slow-burning type of con struction is to be recommended for most factory and warehouse buildings. In some cases, where the contents will be extra inflammable, the extra expense of the thoroughly fireproof reinforced concrete structure is warranted; otherwise mill construction should be used.

In order that there shall be no misunder standing of what is meant by mill construction, we shall say that it consists in disposing the timber and plank in heavy solid.masses so as to expose the least number of corners or ignitable projections to fire. Also it consists in sepa rating every floor from every other floor by fire stops.

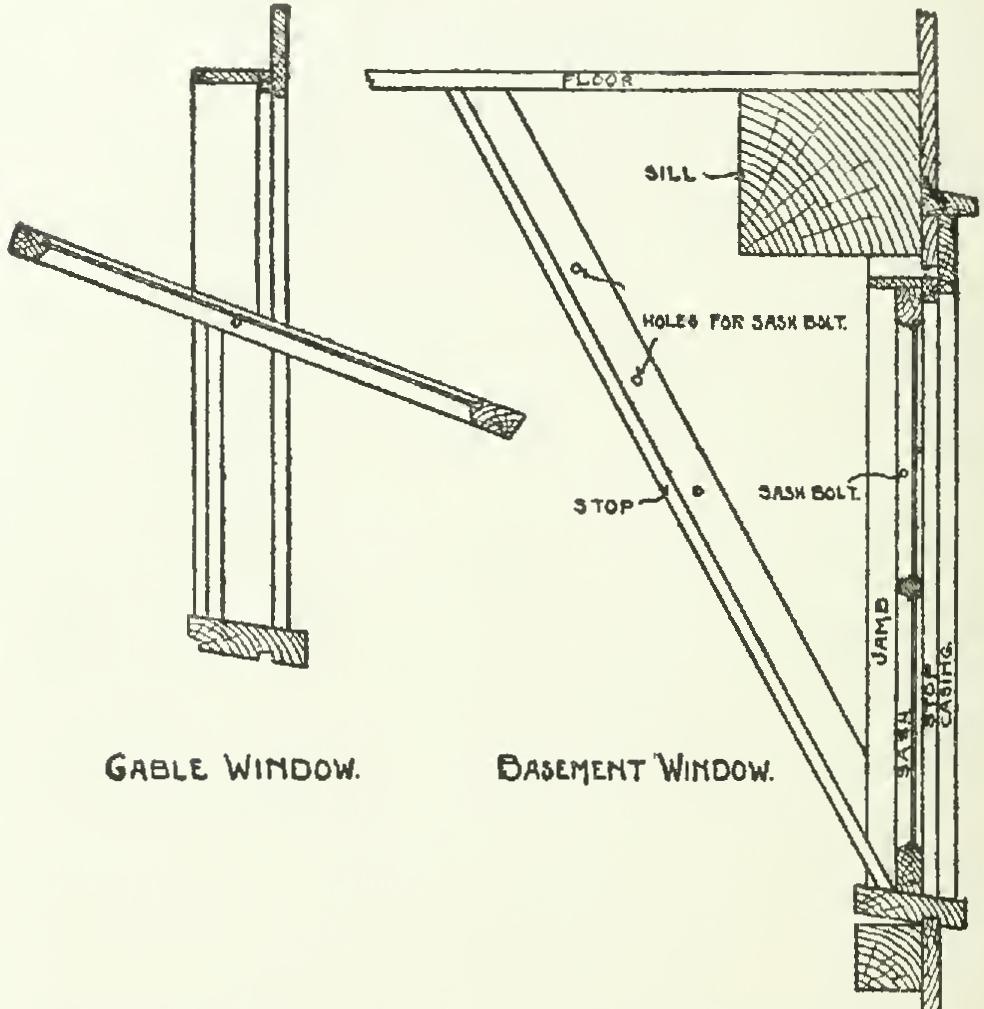

The essential features of standard mill con struction are illustrated in Fig. 149, and are, briefly, as follows: 1. The walls should be of brick or concrete block, at least 1 foot thick (16 inches for best work) in top story, and increased in thickness at lower floors to support additional load. The pilastered wall has many advantages, and is often preferred to the plain wall. Window and door arches should be of brick; window and out side door-sills and underpinning, of granite or concrete.

2. The roofs should be of 3-inch pine plank, spiked directly to the heavy roof timbers and covered with 5-ply tar and gravel roofing. Roofs should pitch 1/2 ineh to inch per foot. An incombustible coraice is recommended when there is exposure from neighboring buildings.

3. Floors are best made of spruce plank 4 inches or more in thickness according to the floor loads, spiked directly to the floor timbers and kept at least 1/2 inch clear of the face of the brick walls. Figs. 150 and 151 show bad and good forms of floor construction. In floors and roof, the bays should be 8 to feet wide; and all plank two bays in length, laid to break joints every 4 feet, and grooved for hardwood splines.

Usually top floor of birch or maple is laid at right angles to the planking; but the best mills have a double top floor, the lower one of soft wood laid diagonally upon the plank, and the upper one laid lengthwise. This latter method allows boards in alleys to be easily replaced when worn, and the diagonal boards brace the floors, reduce vibration, and distribute the floor load even better than the former method.

Between the planking and the top floor should be two or three layers of heavy tarred paper, laid to break joints, and each mopped with hot tar or similar material to produce a reasonably water-tight as well as dust-tight floor.

Rapid decay of basement or lower floors of mills makes it desirable, whenever wood is not absolutely necessary, to provide cement floors for these places. If wooden floors are required, crushed stone, cinders, or furnace slag should be spread evenly over the surface and covered with a thick layer of hot tar concrete, on which is often laid tarred felt, well mopped with hot tar or asphalt. On this a floor of 2-ineh seasoned plank should be pressed, nailed on edge without perforating the waterproofing under it, and the hardwood top floor boards nailed across the plank. Cement concretes promote decay of wood in contact with them. If extra support is required for heavy machinery, independent foundations of masonry should be provided.

4. In regard to timbers and columns it should be remembered that all woodwork in standard construction, in order to be slow-burning, must be in large masses that present the least surface possible to a fire. No sticks less than 6 inches in width should be used, even for the lightest roofs; and for substan tial roofs and floors, much wider ones are needed. Timbers should be of sound Georgia pine; and for sizes up to 14 by 16 inches, single sticks are preferred; but timbers 7 or 8 inches by 16 are often used in pairs, bolted together without air-space between. They should not be painted, varnished, or filled for three years because of danger of dry rot; and an air-space should be left in the masonry around the ends for the same reason. Timbers should rest on cast-iron plates or beam boxes, in the walls, and on cast-iron caps on the columns, as shown in Figs. 152, 153, 154, and 155.