Elements of Steel Construction - Raw Materials 1

ore, iron, lake, superior, tons, cent, loaded, red, hematite and region

ELEMENTS OF STEEL CONSTRUCTION - RAW MATERIALS 1. Introduction. The iron and steel indus try is one of our greatest, and yet it is compara tively young. While iron was known to the ancients, it is only within the last forty years that it has been manufactured in large quanti ties. Indeed, it has been estimated that more iron and steel have been produced within the last fifty years than the entire quantity pro duced in all the previous centuries.

Two causes can be assigned in explanation of the marvelously rapid expansion of the industry. The first was the invention of the steel-frame fireproof structure, which, in the construction of office and industrial buildings, has largely taken the place of the old-time timber and masonry. This type of building may be said to date from the erection in 1884-5 of the Home Insurance Building, in Chicago, Ill.—the original "sky scraper"—which was designed by W. L. B. Den ney, a Chicago architect, and which soon attract 95 ed a world-wide attention and following that opened up an unlimited field for the application of steel shapes in the erection not only of build ings, but also of bridges and other structures.

The second cause which has played an impor tant part in contributing to the increased de mand for structural steel, has been the distinct ively modern affiance of steel and concrete in what is known as the reinforced concrete type of construction, dating from about 1895. The increasing structural applications of reinforced concrete-steel, as it is sometimes known—is one of the most striking features of the present era of industrial development.

In point of capital invested ($1,528,979,076), annual wages paid ($381,875,499), and gross value of yearly product ($803,968,273), the iron and steel industry stands first in rank; while in number of employees (733,968) it is second, that of the manufacture of textiles being ahead*. When it is seen that the number of employees is greater than the combined population of the cities of Cincinnati and Buffalo, is half as great as the population of Chicago, and is greater than the combined number of people in the States of Maine and Nevada, and that if the yearly income from the industry were applied on the national debt it would wipe it out in about thir teen months, we can readily appreciate the magnitude of its importance.

2. Iron Ore—Production and Classes. Iron *12th Census Reports.

ore occurs in almost every country of the globe. In its production the United States stands first, with 52,955,070 long tons in 1907—or about fifty per cent of the world's output. Germany comes next with an output almost equal to that mined in the State of Minnesota. Great Britain comes after Germany; and then come Italy, France, Russia, and Austria-Hungary, with outputs scarcely equal to or little larger than that of our two greatest mines.

Iron ore is divided into classes according to its chemical composition. The various kinds are: Magnetite, Brown Hematite or Limonite, Red Hematite, and Carbonate or Siderite. Mag netite is so called on account of its peculiar prop erty of affecting the magnetic needle. The

difference between brown and red hematite is that the "brown" has water occurring in it in chemical combination, while the "red" has not. All iron ore may have water occurring in it in a mechanical way—that is, as dampness—in which case it is heated in large tanks and the water driven off as steam. This is done in order to reduce the weight and therefore the freight charges, and also to reduce the amount of fuel required for turning the ore into cast iron. Practically ninety per cent of all iron ore used in this country is red hematite.

The United States imports a small amount of iron ore, almost all the imported supply coming from Cuba, which ships us about one half of its production.

Of

the 52,955,070 tons mined in the United States in 1907, 42,245,070, or about eighty per cent, came from the "Lake Superior Region," which is that portion of the States of Michigan, Minnesota, and Wisconsin lying at the western end of Lake Superior. Of this amount, Wis consin produces about two per cent. Alabama is the greatest iron ore State outside of Michi gan and Minnesota, since it produces about one half of the United States ore which is not produced in the Lake Superior Region.

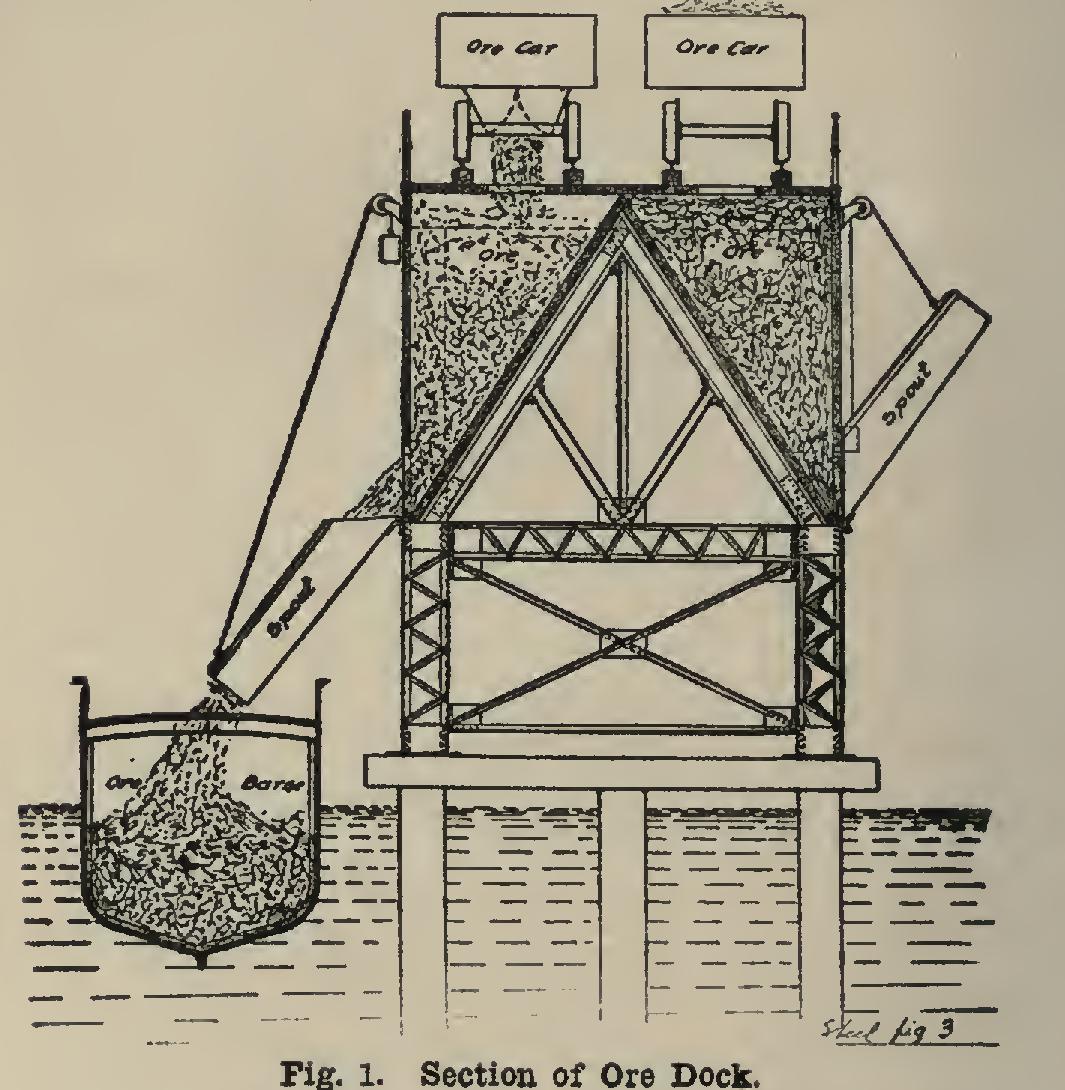

3. Occurrence. The ore may occur at con siderable depth below the surface, in which case it is mined by the use of shafts and cross-head ings, the method being similar to that employed in coal mining; or it may occur in form like loose clay and in huge pockets, or in heaps or small mountains, at a short distance under the surface, in which case the surface dirt is stripped off by means of steam shovels and the ore is loaded on by the same means. Many of the mines in the Lake Superior Region are of this kind, and the ore is taken out very economically, loaded on cars, and shipped to the ore docks at the lake. Here it is stored in the dock hoppers; and when a boat comes to be loaded, spouts are lowered to the several hatches of the boat, and the coal thus delivered on board. See Fig. 1 and Plate 1. These huge steel barges can carry as much as 12,000 to 13,000 tons at a time, can be loaded at the rate of about 100 tons a minute, and unloaded at the rate of 35 tons in the same period of time.

After the load has been put on board these barges, for only about one per cent of the ore of the Lake Superior mines is carried all the way to the furnaces by rail, they proceed in tow or under their own steam to the port of Gary, Indiana, at the southern end of Lake Michigan, or to one of the ports on Lake Erie, where they are unloaded and their contents either put in large piles or taken directly to the furnaces, a large majority of which are in Pennsylvania.

4. Ore Ranges. The ore fields of the Lake Superior Region are named after the respective ranges in which they occur. Table I gives the names and location of these ranges, as well as their output for 1907, and the approximate date of opening. The approximate cost of a ton of ore delivered is $4.00.