Mill Buildings 58

roof, feet, trusses, truss, pitch, angles, stresses, spans, plate and value

MILL BUILDINGS 58. Buildings which are used for manufac turing purposes are usually classed as mill buildings. They may be entirely of steel, or they may have brick walls and steel roofs. The steel roofs may be covered with a steel roof covering or with slate, shingles, tile, concrete, or any other roof-covering.

In any case, mill buildings usually consist of a series of bents (Plates 19 and 20), which con sist of a pair of columns supporting a roof truss and, in many cases, a crane also, which runs lengthwise of the shop. In some cases the col umns carry the wall covering; in other cases the columns carry the roof truss only, masonry walls being built in between them; while in still other cases, there are no columns at all, the roof trusses resting directly upon the tops of masonry walls.

The roof trusses are connected by beams on which the roof cover is supported. These are called purlins. The columns are connected by members running horizontally, and these mem bers are the supports of the walls of the build ing. They are called gilts (see Plates 19 and 20). The space between any two bents is called a bay.

The covering is usually of corrugated iron. Since the strength of the iron is such as safely to carry a man if it is supported at its end by sup ports 5 feet apart, the spacing of the purlins on the truss should not be greater than 5 feet. The girts must be strong enough to carry the weight of the siding, and also to withstand the wind pressure. This wind pressure is usually assumed at 30 pounds per square foot of wall surface. The spacing of girts should be limited to 5 feet in order not to have the corrugated steel stressed too greatly by the wind.

The length of bays is an important factor in the cost of the building. This varies with the span of the roof truss. For spans of from 10 to 20 feet, the bays should be 10 to 12 feet in length; for spans of from 30 to 60 feet, 15 feet in length; for spans of from 60 to 80 feet, 20 feet in length; and for spans of from 80 to 150 feet, 21 to 25 feet. In many cases, wooden in stead of steel purlins are used; and then the span is one foot short of the standard lumber lengths, being 11, 13, 15, 17, and 19 feet, in order that 12, 14, 16, 18, and 20-foot joists respectively may be used for purlins.

The pitch or slope of the roof truss is impor tant. In case the roof-covering is of tar or pitch and gravel, it should be small, or on warm days the roof-covering would run. In case tile, shin gles, or corrugated iron are used, the pitch should be steep, or the rain will beat up under the covering at its laps, and cause leaks. For concrete roofs, the slope may be small or great as desired. It might be said that for pitch or tar roofings, the pitch of the roof should be or less, while for the other classes it should be over A usual pitch for the latter class is or 30 degrees, either of which gives satisfactory results.

The effect of the pitch of the truss on the weight is small for slopes from to pro vided the lower chord of the truss is horizontal.

If the lower chord is raised, the difference will be considerable, and comparative design should be made to determine the most economical pitch.

Purlins are most economical when made of Z-bars, in which case the section modulus given in Table X should be used.

Channels and Z-bars are the best for girtsf or, if the length of bays be great, I-bars may be used. Angles have been used in some cases, but they are not economical.

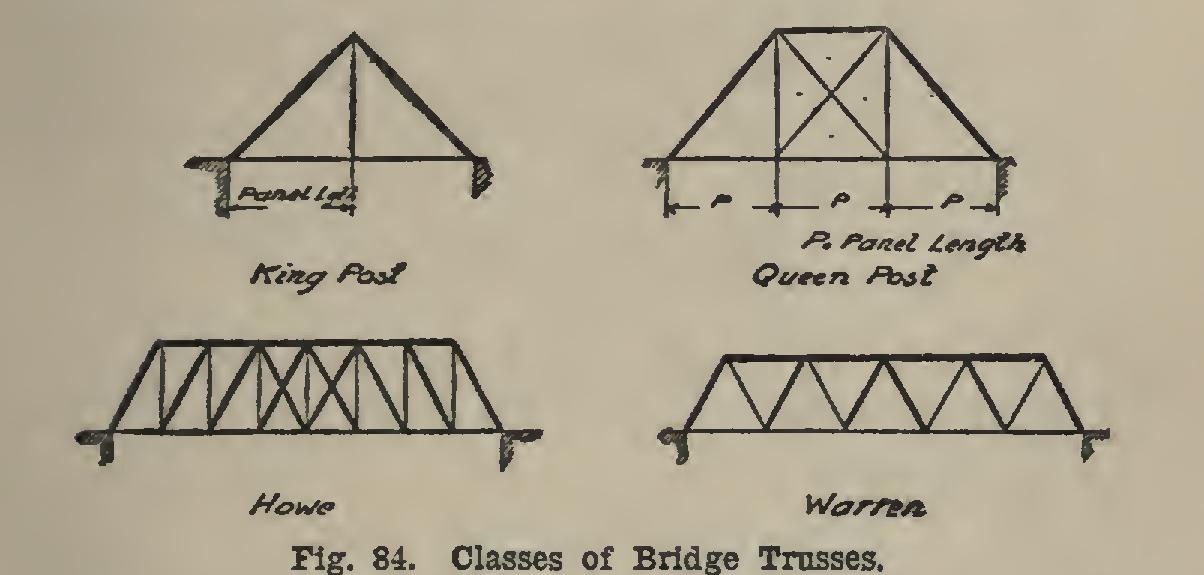

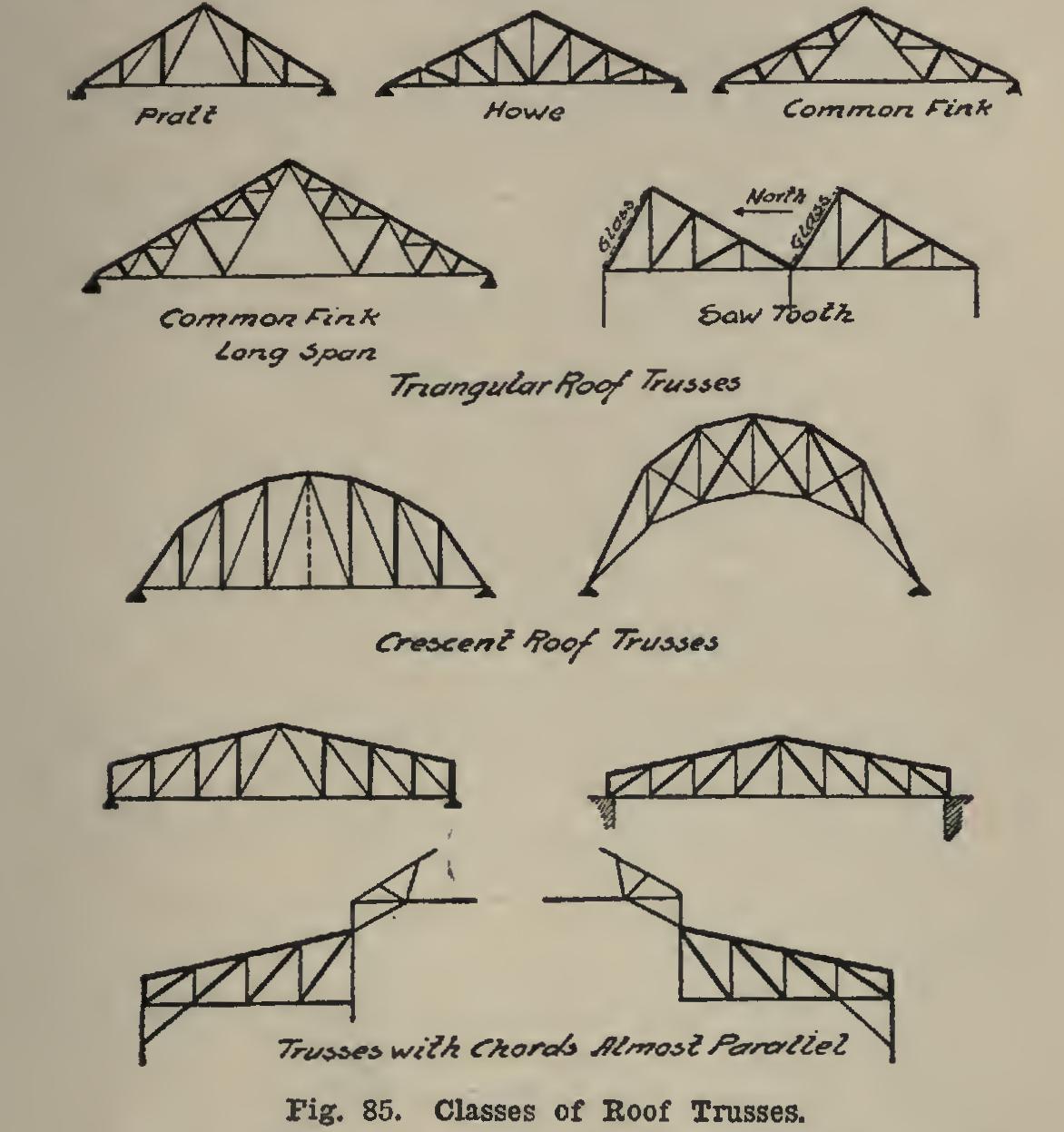

59. Design of Roof Trusses. There are sev eral types of roof trusses (see Fig. 85). The design of these is made after the manner pre viously given, the stresses being once deter mined. The loads are given in the specifica tions, and the approximate weights are also given.

The stresses may be determined by the methods of mechanics; or, for the most usual forms and slopes, they may be determined by (C 173-174). The methods given are for trusses which rest upon masonry walls. In the case of stresses in trusses which rest upon columns, the stresses are greater in some members than in others. The computation of such trusses is rather complicated; but if the stresses in the members be and bf as computed by (C 174) are doubled, and the stress in gc is increased by the trusses will be safe, and will do for all practical purposes.

Most of the members of roof trusses of ordinary spans, consist of one or two angles. If one angle is used in either tension or com pression, tables (C 109 to 119) may be used. If two angles are used in compression, the tables in (C 144-146) are to be used, the least value of the radii of gyration being employed. Usually the angles are inch apart, owing to the fact that the connection plate goes between them. In such cases, use or whichever is the least.

Connections of members are made in most of the ordinary spans—and should be in all spans up to 125 feet—by means of rivets. In this case the bearing value of the rivet in the connection plate, or its value in single shear, is used, taking the smaller value if the case is one where one angle joins the plate. If the member consists of two angles, then the value of the rivet in bearing in the plate determines the number of rivets. In each case, whether the member is in compression or in tension, the number of rivets is obtained by dividing the total stress in the member by the value of the rivets.

Care should be taken to see that the gauge lines of angles, when three or more meet at a joint, should all meet at the same point, as in Fig. 86, a, and not as in Fig. 86, b. When they meet as in Fig. 86, b, extra stresses are set up in the members and the plate; and these stresses are additional to those caused by the loads on the truss. This is a quite common fault, and, in addition to showing poor design, may in extreme cases cause failure of the joint.

Clip angles should be used in all cases where an angle connects to a plate.