Rivets and Riveting 22

rivet, bearing, value, plate, pounds, shear and thickness

Since, in a riveted joint, we do not wish the rivet to fail, we must select some unit-stress less than enough to destroy it. Such stresses are given (C 195), being 6,000, 7,500, 10,000, and 12,000 lbs. per square inch.

In order to get the number of pounds which should be allowed on one rivet in double shear, the value for single shear is found, and then doubled. For example, to find the value of a rivet in double shear, under an allowed unit-stress of 10,000 pounds, the value for single shear (4th column on same line as in the 1st column) is 4,420 pounds; and therefore the value in double shear is 4,420 X2=8,840 pounds.

It is very evident that, where possible, rivets in double shear are the more economical, since only one-half the number that are required in single shear are necessary.

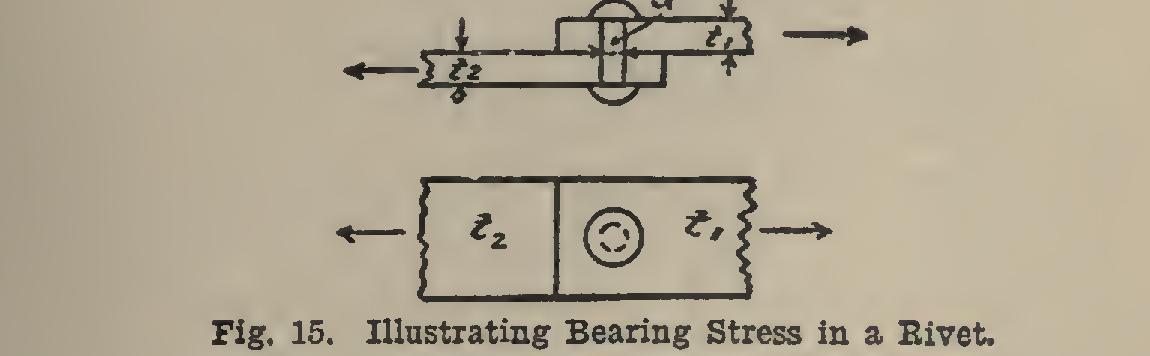

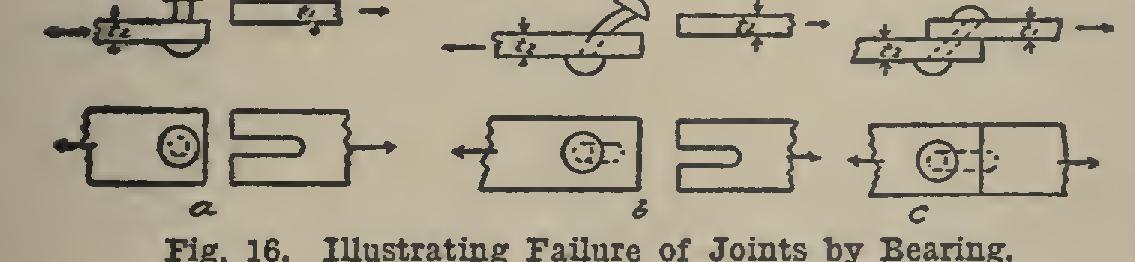

If two pieces of steel are placed close to gether as in Fig. 15, and pulled in opposite directions as indicated by the arrows, the rivet might shear off at x. If the rivet were too strong to shear off, it would pull out one or both of the plates, and therefore the joint would look either like Fig. 16 (a) or like 16 (b) after it had failed. When such a failure happens, the Fig. 17. Calculating Allowable Bearing Pressure on Joint.

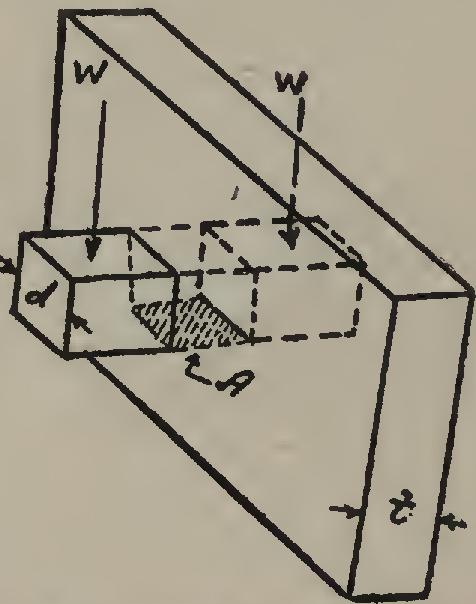

joint is said to have failed by bearing. This means that the pressure of the rivet on the plate was too great, and it pushed its way through the plate, tearing an oblong hole as it went. If the rivet were square in section, it would not take any greater force to pull it through the plate than it does when the rivet is circular in section. The allowable amount of pressure (v) caused by a square or a round pin on a plate of a given thickness, is equal (see Fig. 17) to the area (A) in square inches multiplied by the allowable unit bearing stress (Sb). That is: v=A X Sb, or, more simply, v=ASb.

To get at this result in a still simpler way, the bearing value of a rivet (vb) can be found by taking the allowable bearing stress (Sb), multiplying by the thickness (t) of the plate; and then multiplying the result by (d), the diameter of the rivet or length of side of the bar. This is true since the area A is equal to the product of the thickness of the plate times the diameter of the rivet or side of bar. In other

words, since A=t X d, we have the following simple rule for finding the bearing value of a rivet : vb=t X d X Sb, in which vb--=bearing value of the rivet, in pounds; t= thickness of the plate, in inches; d=diameter of the rivet, in inches; and Sb=unit allowable bearing stress.

In (C 195-196) are given the bearing values of different rivets in plates of different thick nesses, and these are given for unit bearing stresses of 12,000, 15,000, 20,000, and 25,000 pounds respectively. If the bearing value of a rivet in a plate is desired when the unit-stress is 20,000 pounds, is noted in the first column of the third table; then that same line of figures is followed over until the column headed is reached. Here 6,250 is found, and this is the desired value. As a check here, and Therefore, the bearing value Some blanks are left in the tables. The rea son for this is that it is not practicable to use rivets of the smaller diameters in the thicker plates. However, if it were required to obtain a bearing value not given, it is easily calculated from the rule already given. For example, let it be required to find the bearing value of a %-inch rivet in a plate when the allow able unit-stress is 25,000 pounds. Here and Sb=25,000; therefore the bearing value say 11,720 pounds. It will be noted that this result is the same as if we had a rivet in a plate, as shown directly by the table.

In case the thickness of the plate is given in decimals of an inch, the same rule must be fol lowed for determining the value of the rivets, since no tables are given other than those in (C 195-196). For instance, suppose that it is required to rivet something with rivets to the web of a 12-inch 31.50-lb. I-beam. By referring to (C 97), and the 5th column, the thickness is found to be 0.350 inch. If the allowable unit bearing stress is 20,000 pounds, the bearing value of one rivet is vb=0.350 X 20,000=6,125 pounds.