Rivets and Riveting 22

rivet, rod, pounds, fig, length and plates

RIVETS AND RIVETING 22. Rivets are made in different sizes and lengths. The head and diameter are the same for any given size, but the length will vary as the case requires. When the size of a rivet is spoken of, the diameter is usually meant.

(C 191) gives a table of sizes of rivet-heads, showing also the clearances necessary for machine driving.

Rivets are made by heating long rods of the required diameter in a small furnace until they attain a welding heat for a distance of about one foot from the end. The operator then takes out the bar, and sticks the end in the rivet ma chine, which has previously been set so as to make rivets of the required length. The ma chine grips the rod, forms the head by jamming together a portion of the rod, and cuts the rivet off to the proper length. The rivet drops into a receptacle; the machine releases the rod, and the operator shoves it further in, and another rivet is made. This operation is kept up until all the heated part of the rod has been made into rivets. The operator then returns the remain der of the rod to the fire, to get it heated up again, takes out another, and makes rivets out of its heated portion. This action is repeated until all the rivets required are made. If a rod gets so short that the end not in the fire becomes too hot to handle, it is put in the furnace and handled with tongs. In this way the entire rod is used up. As one rod is used, others are put in, and thus the process continues as long as desired.

Rivets were formerly made from a pure grade of wrought iron; but now it is the general practice to make them of soft steel, a material much like wrought iron in physical properties.

The length of the rivet must be such that it will go entirely through the material which it is to hold together, and in addition extend beyond far enough to afford material for form ing the other head. Fig. 12 shows the length, grip, and formation of a second head.

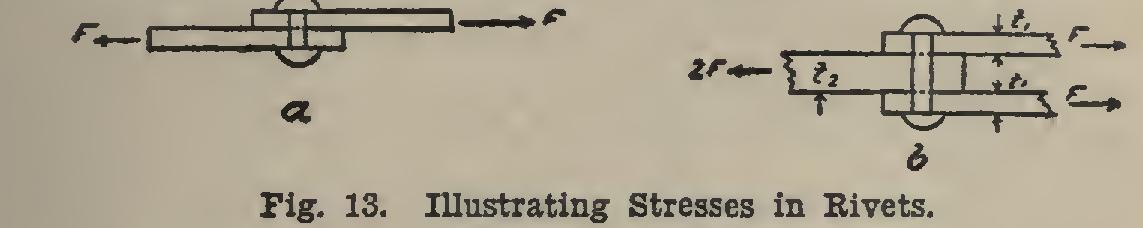

Stresses in Rivets. The stresses which come on a rivet are: Shear, which is the tend ency to be cut across its section; the bearing on the plates it connects; and the tension on the heads, due to contraction. Referring to Fig.

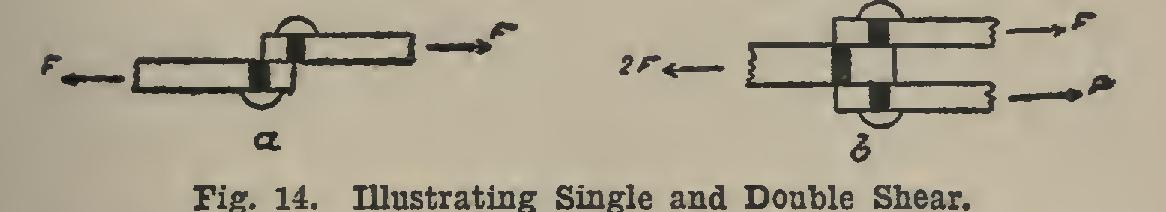

13 (a and b), it will be seen that if the joints are like (a) and the two plates which are pulled in opposite directions are so strong that the rivet will not pull out of them, then it will be cut in two at the point between the plates, and will become as Fig. 14 (a), being sheared off in a manner somewhat the same as if it were cut by a pair of shears. When the conditions are such as shown in Fig. 13 (a), the rivet is said to be in single shear.

In order to find out how many pounds a rivet should stand in single shear, multiply the area of the rivet by the allowed unit shearing stress. In (C 195), fourth column, are given, in the sev eral tables, the number of pounds a rivet should stand if the allowable stress on one square inch of metal is as stated. Thus in the first table the allowable unit-stress is 6,000 pounds; and if the rivet is in diameter, we look in the first column and find and then to the right on the same line in column 4 is found 3,610, which is the value sought. That is, in a rivet joint 3,610 pounds can be allowed for each rivet driven. This allowable stress is quite low, and will perhaps be used in railroad bridge design.

For building design, the last table should be used; and here in the fourth column, oppo site is found 7,220, which is the number of pounds one rivet should stand when the unit shearing stress is 12,000 pounds. The other tables give values for unit-stresses of 7,500 and 10,000 pounds.

In case the joint is as in Fig. 13 (b), the rivet will, providing the plates are strong enough to keep it from pulling out, fail by being cut off at each of the joints between the middle and side plates, Fig. 14 (b). Since just twice as much will be cut as in the case of Fig. 13 (a), the rivet is said to be in double shear.