Steel Shapes 18

plate, plates, inches, width, inch, universal and flats

Squares. These are listed (C 27), and their areas and weights may be found (C 261-266). The larger squares listed (C 263-266) are seldom obtainable except by special order. Their use is confined to supports for bridge ends, and for other similar uses.

Flats.

Flats are distinguished from plates, chiefly from the fact that they can be obtained quite thick in proportion to their width, and their width varies by of an inch. It is not advisable to use flats of widths other than 1, 2, 21/„ 3, 4, 5, 6, 7, and 8 inches, as the other widths are seldom kept in stock and have to be made specially to order.

Flats are seldom used separately, except to take tension, and then they are riveted at their ends. It is a common and almost universal use to use flats for tension by first making them into eye-bars. This will be discussed later on.

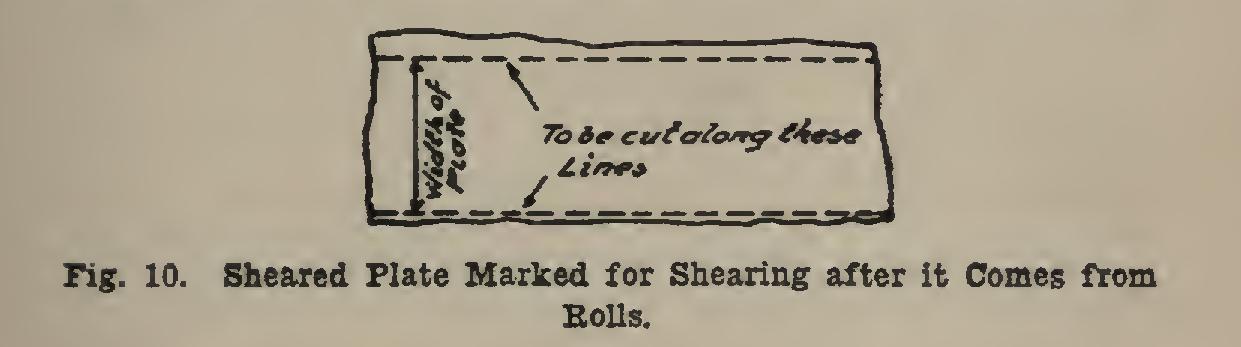

Plates. Plates are of two kinds—sheared and universal. This signifies the manner in which they were manufactured. When the ingot is put through the rolls, it comes out from the final pass as a long, flat plate with irregular edges somewhat as indicated in Fig. 10. Straight lines at a distance apart equal to the width of the required plate, are now laid out, and the plate is then taken to the shearing ma chine and these unequal edges cut off. Sheared plates can always be distinguished by their edges. For sizes and lengths, see (C 30) upper table. At the top of the columns in the table is given a width, and in the next column another width, which differs from the former by a certain number of inches. Suppose, for example, that it is desired to find the length that a 93-inch plate inch thick could be rolled. It would, accord ing to the second note at the bottom, be the same as that for the next widest plate given in the table. The next plate is 96-inch, and the length for that is 130 inches. Therefore the greatest length for a 93-inch plate is 130 inches. If it is desired to have a plate shorter than the lengths given, order it, and the mill people will cut off as much as you want. These plates can be obtained in widths of 48, 49, 50, 51, 52, 53, 54, 55, 56, 57, and so on up to 120 inches, but they cannot be had in widths of a fraction of an inch. If a

plate inches is desired, a 52-inch plate must be ordered, and inch cut off one side.

Universal plates are rolled by four or by six rolls, one pair horizontal and one pair vertical, or one pair horizontal and two pair vertical. Plate 5 (lower figure) illustrates a universal plate roll. The pairs of rolls can be brought as close togeth er or kept as far apart as desired. In this proc ess the plate is rolled to the desired width as well as thickness, and therefore no shearing is neces sary. One great advantage of these plates is that the edge, not being cut, has the same "skin" or surface as the sides of the plate. It will, as a re sult, take paint much better and will not rust so readily.

The sizes and lengths of universal plates are given in (C 30), lower table. As in the case of sheared plates, these plates may be purchased in any inch in width from smallest to the largest, but not in any fraction of an inch except in the case of large orders.

Universal plates should be used when pos sible. They are not used by themselves except to make eye-bars, but they are much used in making built-up members, which comprise a great variety of structural members, consisting of several shapes riveted together.

All plates should be listed by writing first the number of plates of each size; then the width in inches; then the thickness in inches; and finally the length in feet and inches. For ex ample, if we wanted a plate 18 inches wide, inch thick, and 12 feet inches long, we should specify it thus: 1 Pl. or, if the length is less than a foot, 1 Pl. 7" x0' If two or more plates are to be listed, we should write: 2 Pls. 5/-6", or 7 Pls. 3" X X Angles. The angle is the most useful of structural shapes. There is scarcely any built up member of any size which does not of neces sity require angles in its construction; and they are employed either singly or in a pair or pairs to make many smaller members. The angle may be used to take either tension or compression.