Steel Shapes 18

angles, inches, channels, columns, legs, tables, foot and called

Angles are so called because of their shape, the two legs meeting to form an angle; and they are made with equal legs (C 13-14) and with un equal legs (C 14-15). Special angles—square root angles, so called because their angles are all squared—are given (C 16-17), but are very rarely used.

In the tables (C 109-119) are given various useful data relating to angles with unequal and with equal legs. For the present the first five columns will be noted. In column 1 is given the mark by which the rolls can be picked out when it is desired to roll that section. Those sections which have a star (") are special angles. They are not square root angles, but the star indicates that they are not kept in stock, and are not rolled except in large tonnages, unless a high price is charged for them. They should not be used in the design of structures. Some one of the other angles will do.

The size, thickness, weight per foot, and the number of square inches in the section, are given in the next four columns. Do not use an angle thicker than 13/16 of an inch if you can well avoid it. This is about as thick as can safely be punched for rivets. For thicknesses greater than this, the holes must be bored, and this is very expensive. It is, of course, possible to punch material thicker than 13/16 inch; but the thickness of the plate in such cases is too great compared with the diameter of the punch (which is seldom more than 13/16 inch), and the punch is likely to break off in the hole. It will be cheaper to use a larger and thinner angle, even if the area is somewhat greater than that required.

In listing angles the following method is in common use: The large leg (if of unequal legs) should be stated first, the small leg next, the thickness next, and finally the length in feet and inches. The number of the angles required is placed first. For example: 1 L 6"X4"X%" X or 2 L's 4" X 4" x Members composed of angles are either riv eted directly to other members, or are riveted to a plate which is connected to the other member or members by rivets or a plate.

Channels. Channels are used mostly in pairs for compression members—that is, mem bers taking a thrust or push. They are some times used as tension but, on account of the thinness of their webs, the end connec tions are expensive because of the large number of rivets necessary. Channels are much used as beams. In (C 101 and 102) is a table containing a large amount of useful data relative to chan nels.

On account of the many dimensions of a channel, it is simpler to designate them by their depth only, and then give their weight per linear foot, and finally their Thus: 1 [ 9"X 13.25 or 2 ['s 12"X20.50 lbs.—

7'41/2". These signify, in the first case, one channel 9 inches deep, weighing 13.25 pounds per linear foot, and 17 feet 6 inches and, in the second case, two channels, each 12 inches deep, weighing 20.5 pounds per linear foot, and 7 feet inches long.

Those channels whose weights are given in heavy-faced type (like the 8"X 11.25 lbs., 9"X 13.25 lbs., 10"X15.00 lbs., etc.) are called stand ard sizes. Formerly it was necessary to avoid using any others but these; but now most of the large steel companies keep all weights in stock, and any weight can be obtained easily. In columns 5 and 6 are given the dimensions of web and flanges; (C 6 and 7) give the sections; while (C 183-186) give valuable information as to dimensions and riveting in flange and in the web.

1-Beams. The shapes known as I-beams so called from the resemblance of their section to the letter I—are seldom used in any other manner than as beams; see (C 1-5). In some cases, particularly in building members for cranes, they are used to help make compression members. They are much used in building con struction, to form what are known as box gir ders; see (C 152-156). An I-beam should be listed thus: 1 I 24"X80 lbs.-3'-4", which means, one I-beam, height 24 inches, weight 80 pounds per linear foot, 3 feet 4 inches long.

The tables (C 97-100) are for I-beams. They give data for I-beams practically the same as the tables mentioned above do for channels; and the same remarks regarding the tables for chan nels apply to these for I-beams. On (C 175-182) are given tables which contain information regarding the method of fastening in walls, and the position of rivets when such a connection is to be used.

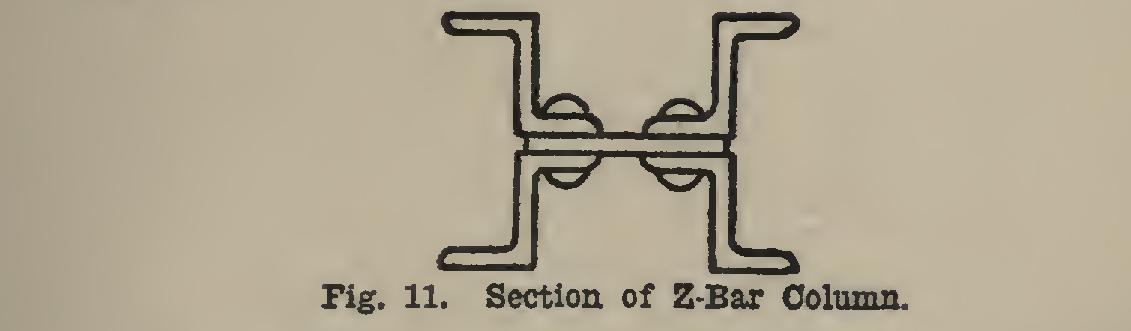

Z-Bars. Information regarding Z-bars (or Zees, as they are sometimes called) is given on (C 10, 11), (C 103 and 104), and (0 189-190). Z-bars are seldom used for anything except columns. The excellent manner in which they can be combined with a plate to form an eco nomical section for compression, and the many faces they have to which connections can be easily made, make them general favorites for columns. Fig. 11 shows how these can be put together.