Stonecutting

masonry, stone, stones, broken, surface and according

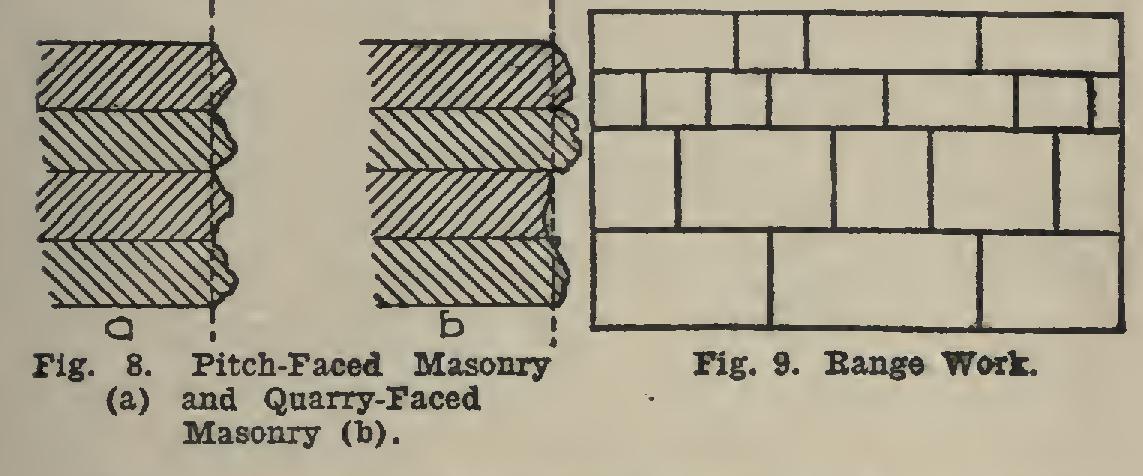

STONECUTTING Masonry is classified (1) according to the kind of material of which it is composed—as Brick Masonry, Stone Masonry, and Concrete Masonry; (2) according to the manner of dress ing the faces and edges—as First-Class or Sesond-Class Masonry, Ashlar, Rubble, Square Stone Masonry, Pitch-Faced or Quarry-Faced Masonry; and (3) according to the arrangement of the material in the wall—as Uncoursed or Dry Rubble, Range or Broken Range Work, and many other similar terms.

In this treatise, only stone and brick masonry will be considered in detail, concrete masonry being reserved for special treatment elsewhere.

Manner of Dressing Stone.

Stones used in masonry are divided into three classes—roughly broken stones as they come from the quarry, with little attempt to make them of regular shape or size; stones roughly broken to conform to some prearranged form and surface; and stones accurately fashioned according to a defi nite design.

Rough broken stone is used when weight is essential, as in breakwaters, as a pavement for shore protection, as retaining walls where space is not limited and appearance is not a factor, and in foundations for walls. The stone may or may not be laid in mortar. When masonry is divided into numbered classes, such construction would be third-class, but it is usually called rubble masonry.

Squared stones

are broken by hammers or axes to nearly straight edges, and the sides are made approximately plane surfaces. The angles are not always square, and a section may be any polygon with obtuse angles, although this form is exceptional. This class and the class follow Crandalled. A tool like that shown in Fig. 5 is called a erandall, and is designed to do the work of the point more quickly and to produce a more uniform result. The tool is made by wedg ing several double-pointed bars about 9 inches long into a handle as shown; and it is used with two hands.

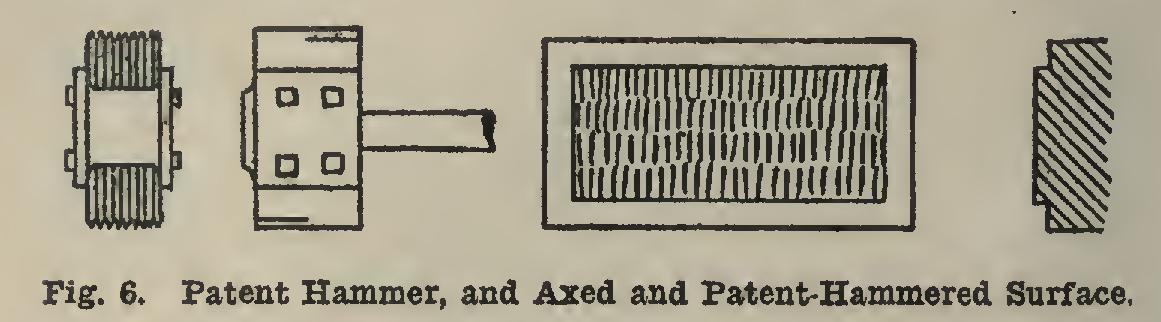

Axed and Patent-Hammered. Axes

and patent hammers make straight marks instead of conical holes in the stone; and these marks are made parallel to one another over the entire surface to be dressed (Fig. 6). The ax makes one mark, and the patent hammer several marks, at each blow. If the edge of the ax be cut to form teeth, the tool is called a tooth-ax.

Bush-Hammered. The bush-hammer is

a heavy tool, about three inches square in cross section, with faces cut to form numerous square, pyramidal points. It is used for the final dress ing of a surface where the point and ax have been used. This manner of finishing is destruc tive to the softer stones, causing them to weather badly. (See Fig. 7.) Many of the soft sandstones and limestones are capable of being worked by machines similar to those used for working wood and iron. Such stone may be planed, mortised, fluted, grooved, and turned with great facility, and the surface is given a smooth or ribbed finish at will. Cut stone tooled in any of the above-mentioned ways is called ashlar or first-class masonry.

Arrangement of Stones in the Wall.

The ar rangement depends partly upon the manner in which the stones have been cut, and largely upon the desired stability and appearance.

Pitch-7aced and Quarry-Faced Masonry. The sketch, Fig. 8, shows clearly the distinction between the two methods of laying the stone. It will be noted in a, that both the upper and lower front edges of the pitch-faced stone are, in the same plane. This arrangement requires con siderable more care than is necessary in break is an analogy between the distinctions of range work and of rubble work; but the latter is made of irregular-shaped stones, while the former is composed of rectangular pieces.