The Masonry Arch

feet, arches, thickness, span, abutment, dimensions and depth

THE MASONRY ARCH The arch is a structure used primarily as a device for covering openings too long to be spanned by beams of reasonable dimensions. Masonry of all kinds is much stronger in com pression than in tension; and by the use of the arch, stresses of the latter variety need not be used.

Fig. 38 shows half an arch, and the parts represented are named as follows: Keystone The stone at B C.

Arch-Ring The stones at A D C B—I Intrados The curve, as A B, on a sec tion parallel to A D C B.

Extrados The curve, as D C, on a sec tion parallel to A D C B.

reduced, and failure may take place by rotation or by further crushing.

External Loads on Arches. Whether the arch be intended to support the masonry over .a doorway; or the spandrel filling, road founda tion, and pavement, with the traffic; or a rail road track or train, there are very many uncer tainties as to the amount and distribution of the load. The usual assumption regarding the effect of a brick wall above an arch, is that the arch should be designed to carry the weight of a triangle of the masonry, whose length is the span, and whose height is half the span. If the arch be flat, this load may be considerable.

The weights of the filling, pavement, track, and moving loads may all be determined with considerable accuracy. The uncertainty as to the way in which these weights act upon the arch, makes necessary some assumptions which may not be exactly true.

If the load is of sand, or is carried to the arch through considerable thickness of sand, it is rea sonable to suppose that it exerts some horizontal pressure. If, on the other hand, the loads are carried down by a spandrel filling of loose rubble masonry, the horizontal pressure must be small.

Experimental Tests on Arches. Perhaps the most notable tests of arches were made by the Austrian Association of Engineers and Archi tects during 1900-1905. The following account of the results is abstracted from "Engineering" (London, February 21, 1896) : time is taken as an example of safe dimensions, and others of similar span and rise are fash ioned after it. Nearly all small arches are built stronger than necessary, as it is cheaper to do so than to cut the stone very accurately to just the dimensions necessary. Few arches are built with less than one foot for the depth of the arch-ring.

Trautwine's rule for the thickness of arches of first-class masonry is : t = Square root of divided by 4, and with 0.2 added, in which t is the depth at the crown, r is the radius of curvature of the intrados, and s is the span, all dimensions being in the same unit of measurement.

If the masonry be second-class, the depth given by this formula should be increased by one-eighth; and if of soft brick, by one-third. For example, let the span be 50 feet and the radius be 30 feet; then, by the rule, t = 0.2+ square root of (30+25) = 2.05 feet. The thickness is usually increased from the crown to the skewback.

Dimensions of Existing Arches. Table 1X gives data regarding some arches that are still standing after years of service. While it is evi dent that they are strong enough, it is not def initely known how much lighter they might have been built with safety. The above formula gives 1.8, 2.47, 3.48, and 4.18 feet respectively for the proper depth of arch-ring for the four spans of Table TX.

Thickness of the Abutment.

There are sev eral empirical rules for designing thickness of abutments. The one here given is credited to the author of Trautwine's Engineer's Pocket Book.

Let t be the thickness of the abutment at the springing; r, the radius; and h, the rise of the arch—all in feet or in the same unit. Then, t=0.2 r+0.1 h+2.0.

This formula is applicable to large and small arches alike, and is thought to be safe whether the abutment stands alone or has a backing of earth on the side away from the arch.

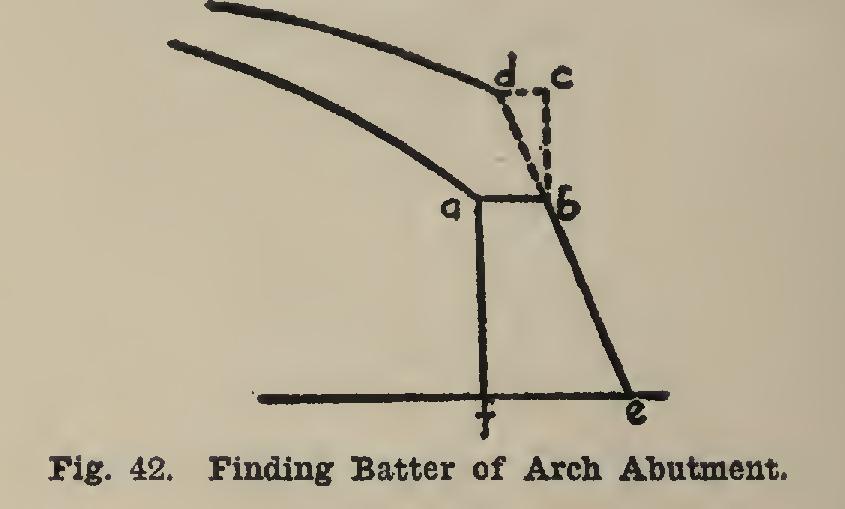

Having computed the proper thickness at the springing, the hatter of the abutment is found as shown in Fig. 42. The thickness a b is laid off; then b c is half the rise, and cd is of the span. This batter is produced downward to the bottom of the abutment, and the point d is joined with the extrados at the crown by a curve. The width of the bottom of must not be less than For example, let the height of the abutment of the second arch in Table 1X be 12 feet. Then the batter on the hack will be 12X3-:-8.25=4.36 feet; and the width of the bottom will be, by the rule, 4.36+2.47=6.83 feet; but the second re quirement makes it necessary to build it % of 12. or S feet wide.