Concrete Block Machines

blocks, cement, feet, machine, sand, size, cubic and mixture

Number of Blocks Required. In estimating the number of blocks required, the simplest method to pursue is to figure out the superficial or face area of the building. First, multiply the length around the building (in feet) by the height of the wall (also in feet) ; let us call this quantity A. Find the surface of gables by multiplying width of gable by its height, and dividing by 2; call this quantity B. Find the surface of each opening by multiplying its width by its height, and add together all the areas of the openings; call this quantity C. Then add together the quantities A and B, and subtract from their sum the quantity C. The result will be the net or actual face surface to be covered with the blocks (in square feet). Divide this by 100 by simply pointing off two figures at the right, and this will give the number of squares of 100 feet each to be covered.

Then turn to Table XX, and multiply your number of squares by the number in the right hand column opposite the size of block to be used. The result will be the number of blocks needed for the building.

For example, suppose the superficial area to be covered is 1,525 square feet. This will be 15.25 squares of 100 feet each. If the blocks are to be 8 by 8 by 16 inches, find this size in the left-hand column of the table, and look across to the right, where you will find the number 112. Then 112 x15.25=1,708, which is the number of blocks required.

Cost of Concrete Blocks.

The following ex ample of cost calculation is based on condi tions that may be regarded as approximately standard: The facing mixture is 1 part Portland ce ment to 2 parts coarse, sharp, clean sand; and the body of the block 1 part cement to 2 parts sand and 3 parts gravel or broken stone, the gravel or broken stone to range in size from one-fourth to three-fourths of an inch in diameter.

One barrel cement contains 3% cubic feet. One cubic yard contains barrels.

One cubic yard of sand and 3% barrels of cement will give a 1:2 mixture of cement and sand.

The figures given in the above table for the weight of hollow blocks and the number produced from one barrel of cement, can, of course, be taken as only approxi mate, since the size of the air-space in different blocks varies. It ranges from about 27 to about 32 per cent, or averages about 30 per cent, of the total space occupied by the block.

One cubic yard of sand and gravel and barrels of cement will give a 1:5 concrete mixture.

For manufacturing 100 blocks 8 by 8 by 16 inches in size, there are needed 2.24 barrels of cement, 0.68 cubic yard of sand, and 1.06 cubic yards of gravel or broken stone. The cost of

making 100 blocks will therefore be approxi mately as follows: 2.24 bbls. best Portland cement @ $2.00 per bbl. .$4.48 Total cost of 100 blocks 8x8x16 in. =$9.00 The above figures are conservative estimates of cost for materials and labor. They may vary to a greater or less degree, depending on the locality—distance from sources of supply, local labor conditions, etc.

Ordinarily blocks cost less than common brick. For comparison of cost with brick con struction, the following figures showing the equivalent number of brick displaced by blocks of various sizes, will be found of help: Kinds of Block Machines. There are two general types into which concrete block ma chines are classified—namely, vertical-faced machines and face-down or horizontal-faced ma chines. These names indicate the position occu pied by the face of the block during the moulding process. In the "face-down" or "down-face" machines, the face-plate forms the bottom of the mould; in the other type, this plate is held in a vertical position. The face-down machine is the more easily adapted to applying specially treated faces to blocks. If a vertical machine is used, the special facing (consisting simply of rich mortar, which may be colored, water proofed, etc.) is placed while the mixture form ing the body of the block is kept back by a part ing plate or other device. In the face-down machine, the facing can be placed directly in the bottom of the mould, and the coarser body mixture be placed above it.

Plate 17 shows groups of solid and hollow blocks, plain and with differently ornamented faces, and gives some indication of the various structural uses to which these shapes may be applied.

Plates 18 and 19 illustrate the application of concrete blocks to house construction and ornamentation. The use of blocks in the con struction of silos, chimneys, smokestacks, etc., is also illustrated in various plates.

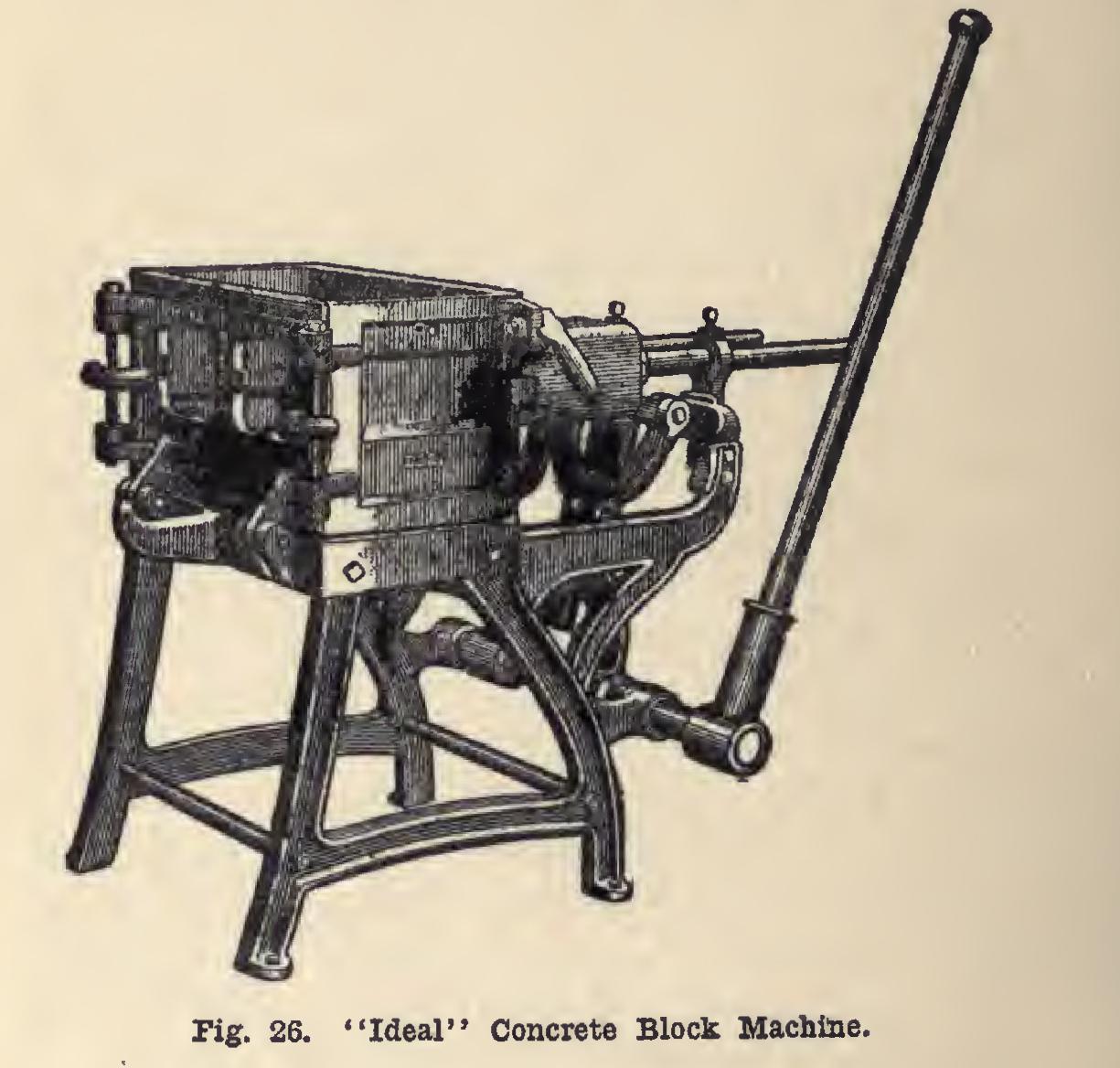

• The "Ideal" Block Machine, illustrated in Fig. 26, is of the face-down type. It embodies Fig. 26. "Ideal" Concrete Block Machine.

the important feature of horizontally removable cores, which are withdrawn by means of a lever while the block is still in the position in which it was made. The block and mould are then swung outward to discharging position, being 41110po 1 s VIII " Viii turned over on one side, when the face- and end plates are released, and the block removed on the pallet. With this machine, fractional-sized blocks in every inch size within the capacity of the machine may be obtained—all with proper marginal effect.