Concrete Block Machines

blocks, plate, machine, cores, material, position and pressure

The "Eclipse" Block Machine, illustrated in Plate 16 (at the left), is another face-down ma chine with adjustable end- and face-plates for making various sizes of solid or hollow blocks, with or without mortar-lock ends. Should it be desired to make blocks of less height than those for which the machine is set, this can be done by means of a second face-plate placed over the original or separated from it by a skeleton wood block, which is turned out with the moulded block. Fractional face-plates can also be used to vary the face treatment, giving angle blocks, blocks curved at various radii, etc.

In Plate 16 (at the right) is shown a hollow block with mortar-lock ends, ready for removal on the pallet from a "Miles" Block Machine.

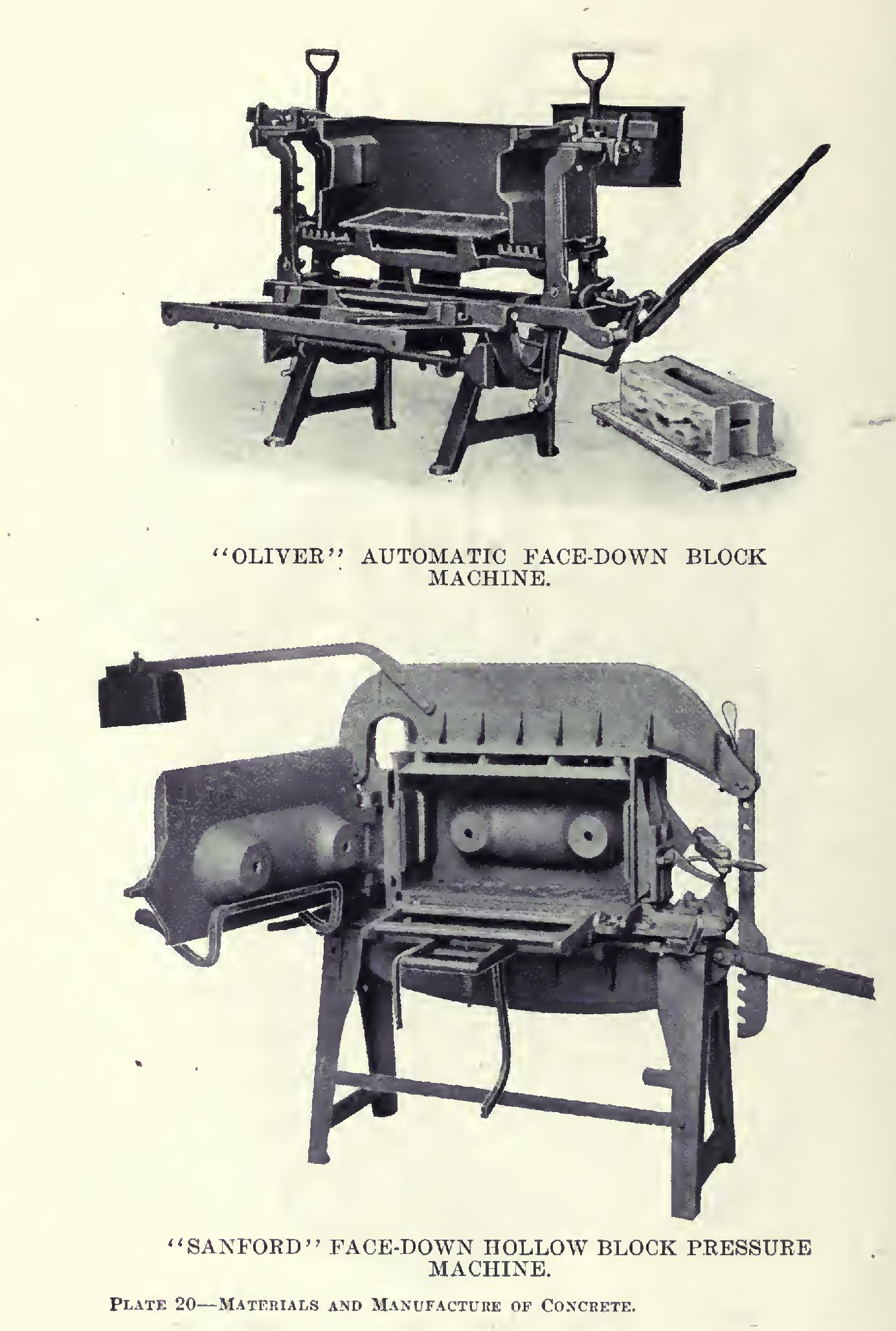

The "Oliver" Machine, shown in Plate 20 (upper figure), is another example of the face down type.

The "Sanford" Machine (see Plate 20, lower figure) is a face-down hollow-block machine of what is known as the "pressure" type. The mould-box is adjustable for different sizes, and the top and bottom plates are interchangeable so that the press can be operated either way. The cone-shaped, rounded cores are shoved into position for charging, by an automatic device that is placed in operation when the doors of the mould-box are opened. They then remain in position until the mould-box is closed and filled with material, and the pressure applied, when they are forced down to the center of the block by the material under compression, thus pressing a block as hard below as above the cores. They make a block, it is claimed, that is "arched or reinforced from every point to the center, at the same time coring both length wise and through the block." Their roundness allows the material under compression to slide over and about them, thus filling the voids. The holes in the apex of the cores remove any air in the center of the mould-box, and act to relieve any vacuum that may be formed in opening or removing the cores when the block is finished.

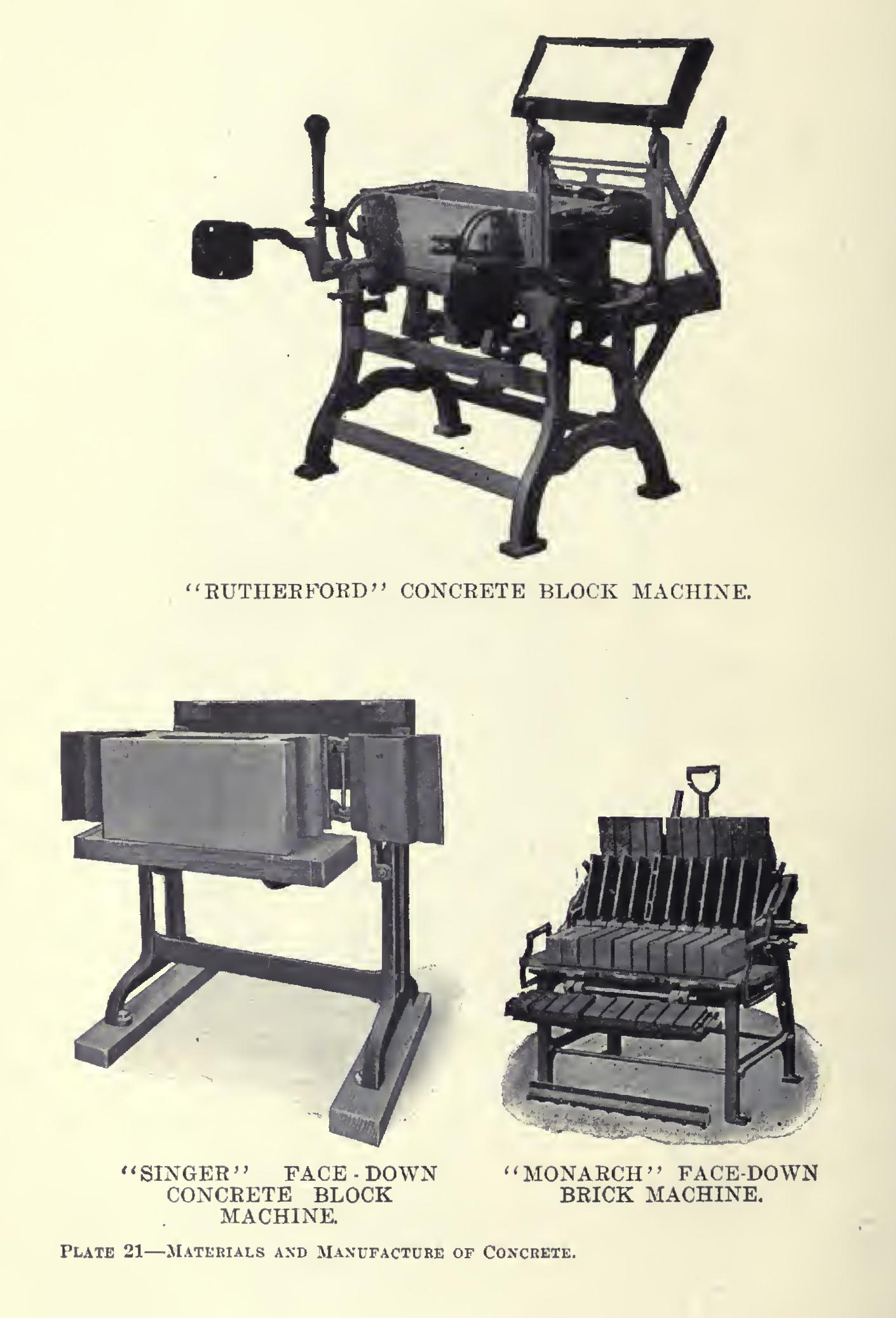

In the "Rutherford" Block Machines (see Plate 21, upper figure)—all of which are of the face-down type—we find a number of appliances for the production of blocks, either smooth, rock-faced, or of ornamental design, for ordi nary construction; also blocks specially adapted for cellar walls or large buildings. These blocks be tongued-and-grooved, top and bottom, the tongues and grooves being made by means of slides, which, after the blocks are formed, are easily removed from the machine. Or blocks

may also be made with a half-round recess at each end, which allows the blocks to be placed close to each other, and the recess can be filled with cement or mortar, thus making the wall impervious to wind and showing a joint of one quarter of an inch.

The mould-board frame on which the face plates are fastened has longitudinal slots which permit the interchanging of the plates, so as to produce a great variety of combinations.

Different-sized cores may be used when de sired; also extra cores when blocks are needed for window-frames or sill-blocks with taper. In some of these machines the frame has a slide movement whereby the face-plate is removed from the block, instead of the block being drawn away from the face-plate, this feature, it is claimed, being important for avoiding cracks or other injuries to the face of the block.

In the "De Armon-McKinney" Block Ma chine, illustrated in Plate 22 (at the left), we have what is known as a "double-pressure machine. The mechanical principle applied is that of obtaining pressure from a toggle-joint arrangement operated by a lever. With this device, a pressure of 72,000 pounds is secured. This enormous pressure is applied on the top and bottom of the block at the same time. No hand tamping is necessary.

This machine is also of the face-down type. The facing material is placed in the moulding box, covering the plate about one inch thick, after which the grouting is filled in just even with the top of the moulding box and stroked off, thus obtaining a uniform amount of material for each block. The power lever is then brought from a perpendicular to a horizontal position. The end doors are thrown open by means of the latch levers, which also remove the end cores. The block is turned one-fourth over by throwing the pallet to a horizontal position, and the fin ishing plate is then removed from the block by the use of a lever and returned to the proper position for the next block. The block is now resting free on the pallet ready to be removed to the drying racks.

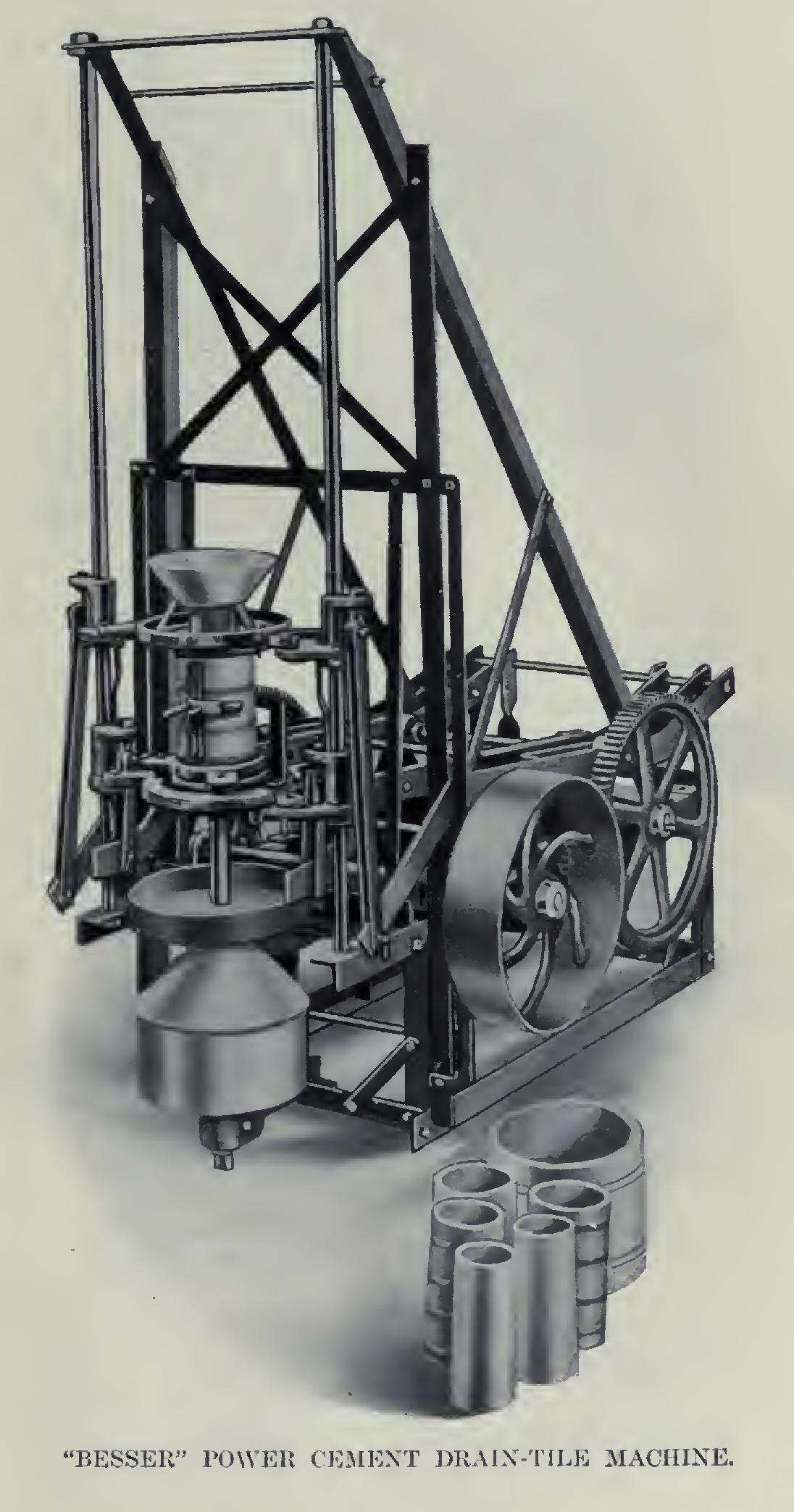

Other block machines illustrated are the "Singer" (Plate 21, lower left figure) and the "Besser" (Plate 22, upper right figure).