Depositing Concrete

cement, day, surface, wet, board, clean, water, spading and placing

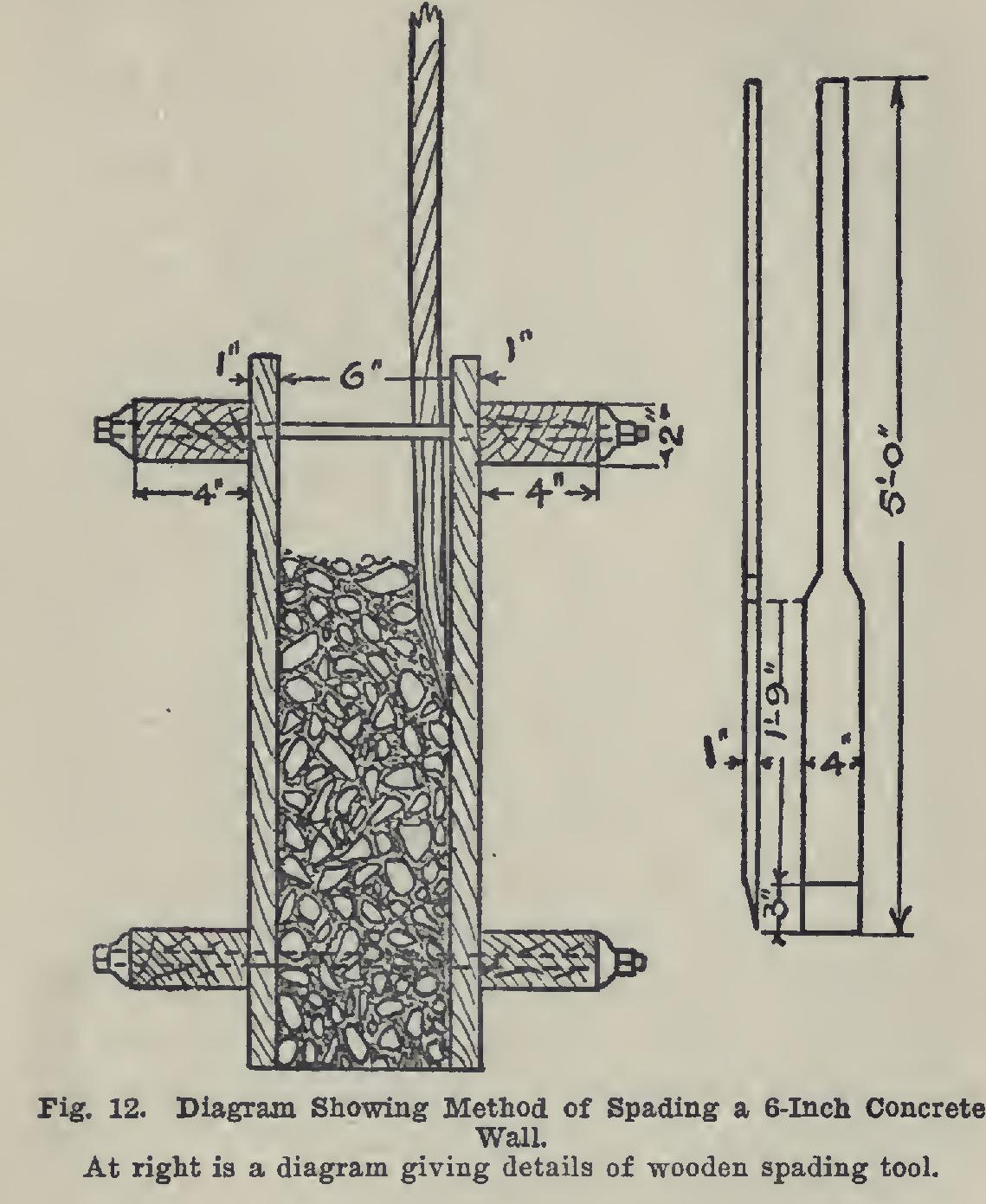

Spading. In order to insure a smooth, un broken face on the concrete, it should be care fully spaded next to the forms, where the fin ished concrete will be exposed to view. And this is true whether the mixture be dry, me dium, or very wet. The operation of spading consists in running a spade or flattened shovel down against the face of the form, and work ing up and down. This action causes the stone or gravel to be pushed back slightly from the form, and allows the cement grout to flow against the face of the form and fill any voids that may be there, thus making the face of the work present an even, homogeneous appear ance. Where the narrowness of the concrete section, such as in a 6-inch silo wall, prevents the use of a spade, a 1-inch by 4-inch board, sharpened to chisel edge on the end, will do as well. Only sharpen on one side, and place the flat side against the form, as shown in Fig. 12. In the case of a dry mixture, spading must be done with greatest care by experienced hands, to get uniform results; but with a medium or very wet mixture, it is very easy to obtain first class work; indeed, with a wet mixture, spading is required only as an added precaution against the possibility of voids in the face of the work, and is really necessary in few cases.

In

spading, be careful not to pry with the spade, as this may spring the forms.

Protection of Concrete after Placing.

Green concrete should not be exposed to the sun until after it has been allowed to set for five or six days. Each day during that period the con crete should be wet down by sprinkling water on it, both in the morning and afternoon. This is done so that the concrete on the outside will not dry out much faster than the concrete in the center of the mass; and it should be carried out carefully, especially during the hot summer months. Old canvas, sheeting, burlap, etc., placed so as to hang an inch or so away from the face of the concrete, will do very well as a protection. Wet this as well as the concrete. Often the concrete forms can be left in place a week or ten days; this protects the concrete during the setting-up period, and the above pre cautions are then unnecessary.

Cleaning the Concrete Board.

When the day's work is done, carefully clean all the tools, especially the concrete board. Remove with a shovel all the loose cement, sand, and stone. Then scrub the board with a broom and water. If this is not done, small particles of stone are glued to the board by the cement, and render shoveling the next day most difficult.

Bonding Old and New Concrete.

Consid erable care is necessary in order to secure a perfect bond or joint when new concrete is to be connected to old, or when a job of concreting interrupted for a considerable time is resumed, as when workmen quit work one day to take it up again the following day.

In ordinary work subject chiefly to com pressive strains, as in foundations, it will be sufficient if the surface of the concrete laid one day is merely washed with clean water before laying on the new concrete the next day; but in walls and floors, or where tensile stresses will be developed, the surface to be joined should be thoroughly washed clean and soaked with water, and then painted either with neat cement (cement and water) or with a very thin, rich mortar consisting of 1 part cement to 1 part sand. If the old surface is very dirty, it may be necessary, after washing it as clean as pos sible, to pick it with a cold chisel in order to expose a perfectly clean and somewhat rough surface of concrete.

It will always help in the subsequent secur ing of a good bond with later work, if the old surface, after ramming or troweling, is scratched or roughened.

Where a water-tight wall is desired, as in a tank, if the concrete is laid in successive tiers and not by one continuous operation, special joints should be made which will give a me chanical as well as a chemical bond. They may be square or V-shaped in section, and either horizontal or vertical. Such joints are moulded by placing pieces of timber so that they will form grooves in the surface of the concrete when the last layer is placed each day, then re moving the wood the following day, and coating the joint with neat cement or very thin, rich mortar before placing the next layer of concrete.

Concreting in Frosty Weather After concrete has once firmly set and hard ened, frost has no effect upon it. It is different, however, if frost is allowed to attack the con crete while being mixed or placed, or during the setting process.

Many special tests and many investigations of work in progress have been made, in order to determine the effect of freezing upon Portland cement concrete before it has had a chance to set. While some difference of opinion on this subject exists, it is the generally accepted con clusion of engineers that freezing does not mate rially affect the binding quality of good Port land cement, and that concrete laid in freezing weather will not be injured provided it does not freeze till after placing, and provided also that it is not subjected to any load until after it has been thawed out and allowed to set in the usual way. The freezing simply retards the process of hardening, which will again proceed under favorable conditions, until the concrete event ually develops its full strength.