Miscellaneous Data

wool, mineral, floor, wood, strips and material

MISCELLANEOUS DATA Portland Cement Industry. A graphic illus tration of the remarkable growth of the Port land Cement Industry in the United States, as compared with the advances made in other in dustrial lines, is given in the accompanying dia gram (Fig. 28), which is based on a chart pre pared by Mr. John Birkinbine, of the Birkinbine Engineering Offices, Philadelphia. The curves also afford comparison with the increase in popu lation, monetary circulation, etc.

Beginning at the bottom of the chart with less than a million barrels in 1890, the cement line is gradual in its rise until 1896, when its upward tendency becomes pronounced, advanc ing with such rapidity that it soon crosses that of pig iron, extending far beyond all compara tive lines, and finally ending in the great total of fifty million barrels in 1908. It is entirely unique in that it does not show the least down ward tendency at any point, a record no other industry has made. (See also page 12.) Mineral Wool. For purposes of fireproofing, insulation against temperature changes, sound pioofing, etc., mineral wool is a material of con struction that has come into extensive use in recent years. It is a mineral substance of a vitreous nature, in physical form consisting of a mass of fine fibers of irregular thickness inter lacing one another in every direction and thus inclosing innumerable minute air cells. Chemi cally, it is a silicate of magnesia, lime, alumina, potash and soda. The name Silicate Cotton is sometimes applied to it.

Mineral wool is manufactured by converting scoria or slag, together with certain rocks, while in a melted condition, to a fibrous state. It par takes of the nature of glass without its brittle ness, the fibers being soft, pliant, and inelastic. On account of the large proportion of air which it holds in confinement, it possesses a remark able power of resisting the transmission of heat and cold, and hence is of value as a means of frost-proofing and of insulation against heat.

Mineral wool is non-combustible and prac tically indestructible by heat; hence has impor tant value as a fireproofing material. If prop

erly placed, it goes far to reduce the fire-risk in buildings. Even when constructed chiefly of wood, a building may be made to burn very slowly by the use of mineral wool. Wire lath and expanded metal may be used in connection with the filling of mineral wool between the studding and floor joists.

As a non-conductor of sound, mineral wool also has special value, and hence makes a very efficient "deadener" or "deafener" of the floors, walls, and partitions of buildings.

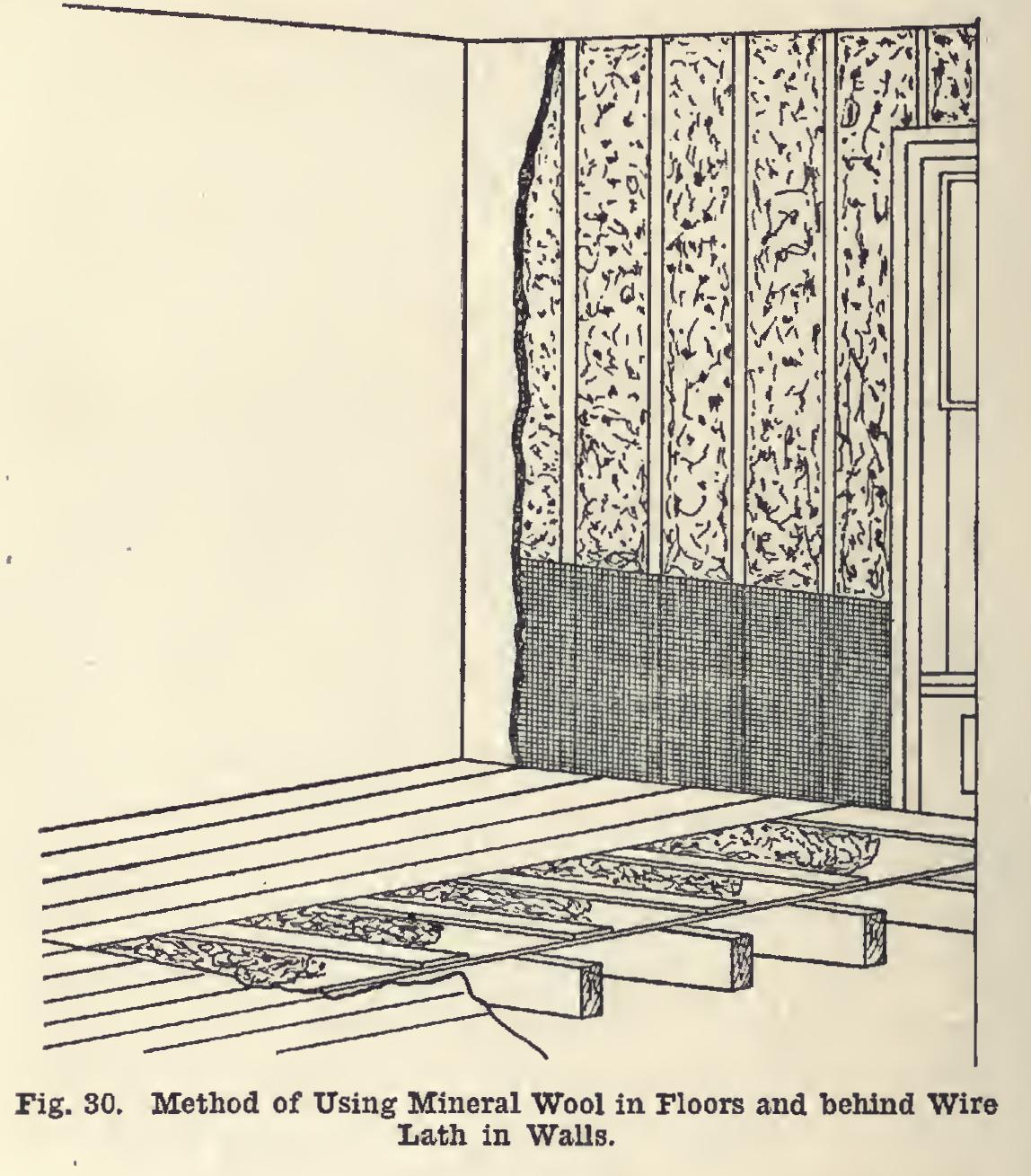

Various methods of applying this material to construction work are illustrated in Figs. 29, 30, and 31. In floors, the plan which gives the best result is to cover the joist with a rough floor, upon which lay wood strips to support the upper or finished floor. These strips should be at least a quarter of an inch thicker than the desired depth of wool. The mineral wool is packed between strips before the upper floor is laid. Another plan is to put a rough sub-floor between the joists, pack in the wool, and lay the finished floor upon the joists. Both modes are shown in ' the accompanying illustrations (Figs. 29 and 30). If strips of fireproof asbestos paper are put under the wood strips in the first mode, or upon top of joist in second plan, it will help to prevent the transmission of sound through the wood work. The wool should not be trampled upon after being put in place.

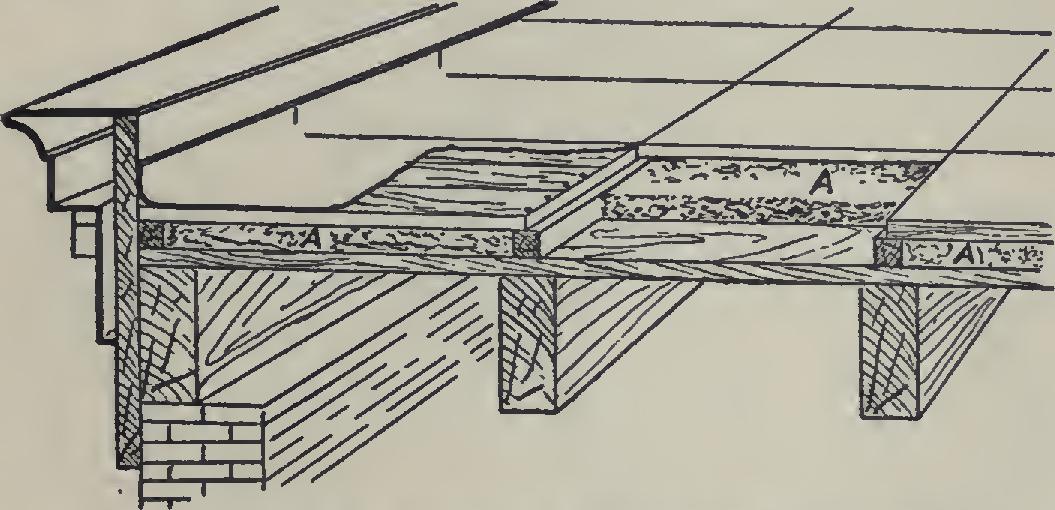

Fig. 31. Use of Mineral Wool for Roof Insulation.

Placed under the roof boards as shown at A, A, A, mineral wool assists greatly in rendering upper rooms comfortable in summer or winter.

In walls and partitions, the wool should be put in at the same time the laths are being put on. Begin lathing at the floor, with either wood or wire lath. After lathing up two or three feet, fill in the wool as high as lathed, then a few feet more of lath, and fill up as before, until the top is reached (see Fig. 30).